The Collaborative Consortium for Coarse Particle Processing Research in Australia will handle multidisciplinary aspects of coarse particle processing such as flotation, comminution, etc.,

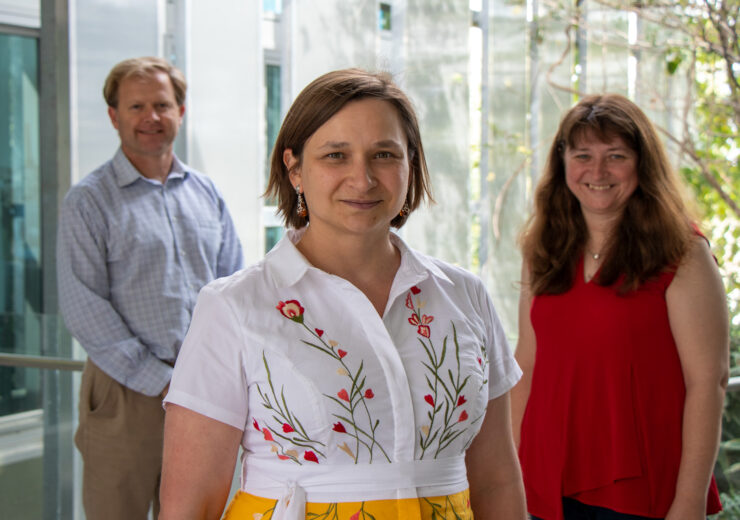

Left to right: Program chair professor Neville Plint, and technical directors Dr Liza Forbes and professor Kym Runge. (Credit: The University of Queensland.)

Australian researchers have signed an agreement with industry partners to form a consortium that will develop improved energy efficiency approach for mineral processing operations.

Under the agreement signed by the University of Queensland’s Sustainable Minerals Institute (SMI), the Collaborative Consortium for Coarse Particle Processing Research (CPR) will operate initially for five years.

This consortium will handle multidisciplinary aspects of coarse particle processing such as flotation, comminution, classification, and equipment design and process chemistry.

It will also help towards addressing global challenges such as reduction of greenhouse gas emissions and human-made climate change.

Details on Collaborative Consortium for Coarse Particle Processing Research

This consortium includes researchers from SMI’s Julius Kruttschnitt Minerals Research Centre (JKMRC) and representatives from Anglo American, Aeris Resources, Eriez Flotation Division, Glencore, Hudbay Minerals, Newcrest Mining and Newmont.

The programme chair is SMI director and professor Neville Plint. JKMRC’s associate professor Kym Runge and Dr Liza Forbes will serve as technical directors.

Professor Plint said: “This consortium brings together depth and breadth of expertise and significant technical skill, and it shows the willingness of industry to work closely with university researchers to tackle complex problems and have an impact.”

“The team in JKMRC have worked hard and consulted with all our industry partners to create this important forum.”

Newmont director of processing Dr Ronel Kappes said the company had identified Coarse Particle Recovery (CPR) to be an important technology to boost the efficiency of processing.

Dr Kappes said: “The UQ CPR Consortium project is an important step in technology development in order to leverage future CPR applications.”

Eriez Flotation Division’s (EFD) Dr Eric Wasmund said: “This consortium fits EFD’s vision to enable sustainable technology solutions through strong customer partnerships.

“As demonstrated by our leading-edge HydroFloat technology, coarse particle flotation is a key disruptive technology for improving mineral recoveries, reducing power and water consumption and producing safer tailings.”

The consortium conducted its first technical workshop at the end of September.