The Australian Renewable Energy Agency (ARENA) has announced a funding of $500,000 ($364,476.82) in funding to support Boral’s subsidiary Boral Timber in producing renewable diesel and renewable bitumen from sawmill residues.

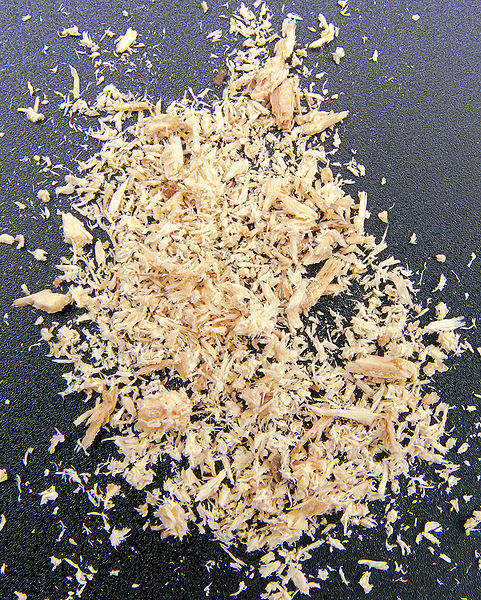

Image: Boral to turn sawdust into biodiesel with ARENA's support. Photo: Courtesy of Rasbak/Wikipedia.org

The funding will be used to investigate the feasibility of building a biofuels refinery, which will use waste sawmill residues from the Boral Timber Hardwood Sawmill at Herons Creek near Port Macquarie.

The sawmill residue includes sawdust, remnant woodchips, shavings and offcuts and they are presently used for lower value uses such as landscaping and boiler fuel.

Under the A$1.2m ($874,488) study, Boral will explore the technical and financial feasibility of establishing a biorefinery which will be located near the Herons Creek sawmill.

If the study is successful, the proposed biorefinery, which is estimated cost A$50m ($36.43m) to build, will have a capacity to convert up to 50,000 tonnes of waste sawmill residue produced each year into transport-grade renewable diesel and bitumen.

The study will examine a mechanical catalytic conversion technology, developed by Global Ecofuel Solutions SL, a Spain-based company, combined with the potential biorefinery at Herons Creek

ARENA CEO Ivor Frischknecht said: “The transport sector is a significant user of energy in Australia, with liquid fuels a key long term energy source for heavy-vehicle road and air transport since they cannot readily be electrified.

“Bioenergy comprises a growing proportion of Australia’s energy mix and this new technology could see residue from the production process be used to reduce Boral’s reliance on diesel and bitumen derived from fossil fuels. If this ground-breaking technology is successful, we hope to see a transition to similar biorefineries by other companies which have a waste stream in forestry or agriculture.”

Boral building products executive general manager Wayne Manners stated that if the feasibility study is successful, the transport-grade renewable diesel produced at the new biorefinery could account for up to 15% of the company’s annual diesel needs.