South Africa’s biggest diamond mine, Venetia, is located in the Northern Transvaal within Limpopo Province in the north-east part of the country. The mine is owned by De Beers, which is a subsidiary of Anglo American.

A reconnaissance sampling programme was carried out by De Beers in 1969 to detect the source of alluvial diamonds. Construction activities at the mine began in 1990, following the finding of viable kimberlite pipes in 1980.

Commissioned in August 1992, the Venetia mine accounts for approximately 40% of South Africa’s annual diamond production. The mine has a surface area of 3.8ha and employs approximately 4,365 people. It produced 4.6 million carats (Mct) of diamonds in 2017.

The existing Venetia open-pit mine will be converted to an underground operation by 2021 to increase the life of the mine to 2046.

Project Gallery

-

The Venetia open-pit diamond mine will be converted into an underground operation by 2021. Image courtesy of De Beers UK Limited.

-

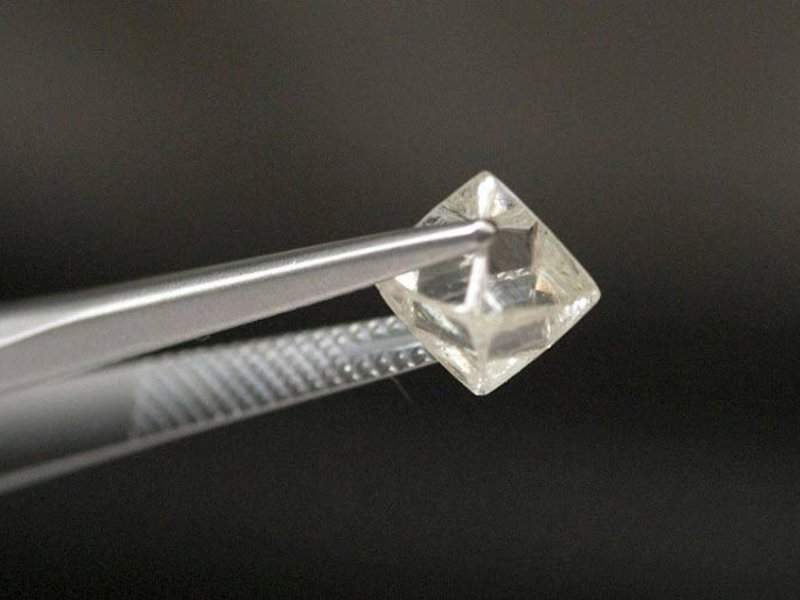

The Venetia open-pit diamond mine produced 4.6Mct of diamonds in 2017. Image courtesy of De Beers UK Limited.

-

The Venetia underground mine is expected to produce 94Mct of diamonds during its estimated life of 31 years. Image courtesy of De Beers UK Limited.

Venetia diamond mine geology

The Venetia kimberlite cluster comprises 14 kimberlite pipes on a surface area of 4km². The kimberlite pipes have been intruded in synform structure.

The first kimberlite, known as K1, is kidney-shaped and is the biggest kimberlites ore body in the structure, with a surface area of 12ha. The second biggest body, K2, is oval-shaped and occupies 5ha of area. The dimensions of K1 and K2 are 640mx260m and 250mx200m respectively.

The cluster also consists of small kimberlite bodies and dykes along the Lezel fault plane, as well as various satellite ore bodies.

Venetia diamond mine reserves

The open-pit mine is estimated to contain proved and probable reserves of 14.7Mt of ore grading 125.5ct/100t and containing 18.4Mct of diamonds, as of December 2017.

The total inferred diamond resources at the open-pit operation were estimated to be 18Mt of ore graded at 17.1ct/100t and containing 3.1Mct of diamonds.

The Venetia underground operation has estimated proved and probable reserves of 98.9Mt of ore, graded at 80.3ct/100t and containing 79.4Mct of diamond, whereas the total inferred diamond resources were 69.9Mt grading 85.3ct/100t and containing 59.6Mct of diamond.

Venetia underground mine development details

The Venetia diamond mine received environmental authorisation (EA) from the Limpopo Department of Economic Development, Environment and Tourism (LEDET) for conversion into an underground mine in October 2012. The environmental management programme (EMP) for the underground operation was granted in the same year.

The development of an underground mine beneath the Venetia open-pit mine is currently underway with an investment of $2bn. Excavation work for the project began in 2013, while production is scheduled to commence in 2022. The underground mine is expected to reach full production in 2025 and create employment for up to 2,000 locals.

The infrastructure required for the mining operation is being developed, including a horizontal tunnel to allow workers to reach the underground mine, and two vertical shafts with a diameter of 7m each to a depth of 1,080m below surface.

Further, a decline shaft, associated ventilation systems, ground and water handling infrastructure, and required surface infrastructure will be developed.

Production from the underground diamond mine

The underground mining operation is estimated to extract 94Mct of diamonds from 132 million tonnes (Mt) of ore during its estimated life of 31 years, according to the life of mine plan approved in 2017.

Contractors involved with Venetia underground mine

Murray & Roberts Cementation received a contract worth R2.6bn ($245m) to build the entire underground mine in July 2014.

Advisian and WorleyParsons provided concept design using 3D designs and performed an advanced feasibility study for the Venetia underground operations.

Mining and processing at Venetia open-pit

The Venetia open-pit operation employs conventional open-pit mining method. The quarry will be mined to a depth of 450m.

The waste rock and kimberlite is drilled and blasted before being loaded and hauled in a conventional truck and shovel operation. The kimberlite ore is stockpiled adjacent to the processing plant and then crushed and processed at the plant to recover the diamonds.

The site also has a waste rock dump facility along the pit boundary and a fines residue disposal facility for the kimberlite fines.