The Green Duba integrated solar combined-cycle (ISCC) power plant is a 600MW project under construction in Tabuk along the Red Sea coast, in the north-western region of Saudi Arabia.

Being implemented by state-owned Saudi Electricity Company (SEC), Green Duba will be Saudi Arabia’s first fossil fuel-fired power plant to utilise solar energy for more efficient power generation.

The integrated project consists of a 550MW gas/condensate-fired combined-cycle facility and a parabolic trough type concentrated solar power (CSP) facility capable of generating up to 50MW of additional electricity.

The environmental impact assessment (EIA) for the project was filed in 2014, while construction works were started after the award of key contracts in 2015.

Project Gallery

-

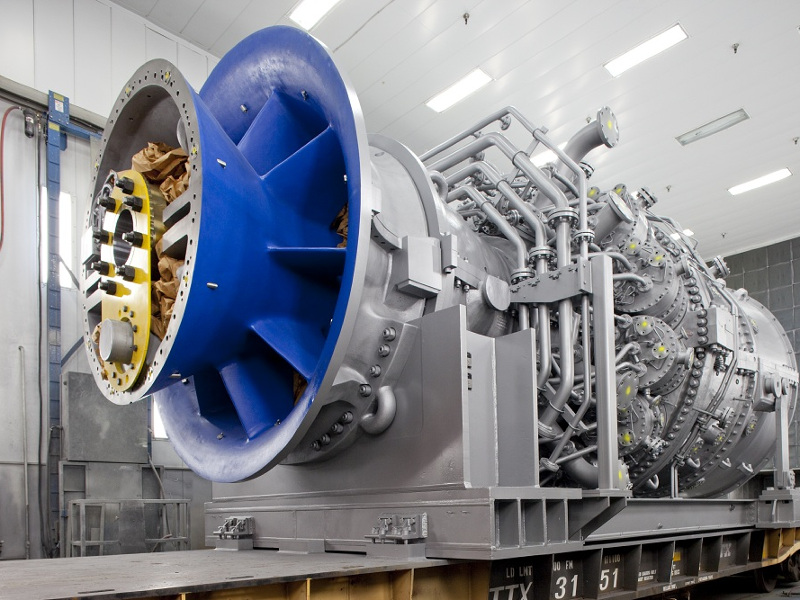

The Green Duba integrated solar combined-cycle (ISCC) power plant uses two GE F-Class combustion turbines. Image courtesy of General Electric.

-

Initec Energía, together with its local partner SSEM, received the EPC contract for the Green Duba project in November 2015. Image courtesy of Intec Energia.

-

Construction works for the integrated solar combined-cycle (ISCC) project were started in 2015. Image courtesy of Dextra Group.

-

The parabolic trough concentrated solar component of the project will produce up to 50MW of electricity. Image courtesy of Z22.

Upon completion, the Green Duba integrated power plant is expected to generate enough electricity for approximately 600,000 households.

Green Duba project background

The project is being developed as part of the Kingdom of Saudi Arabia’s Vision 2030 to diversify its economy by reducing dependence on oil. The project also forms a key part of the Neom futuristic city plan in the bay area of Tabuk in north-western Saudi Arabia.

Project location and regional geology

The Green Duba project site spreads over 160ha of coastal land in the Tabuk province, approximately 55km north of Duba.

The project area is mostly dominated by a sandy beach and has no permanent residential areas nearby or in the immediate vicinity that could be impacted by the project construction.

The Green Duba project site can be accessed via the Duba highway that runs on the east side. The nearest airport is located approximately 140km away, at Tabuk, while the nearest seaport is at Yanbu.

Green Duba combined-cycle power plant details

The Green Duba combined-cycle power plant will feature two GE F-Class gas turbines, as well as a steam turbine generator, two heat recovery steam generators (HRSG), a condenser, and boiler feed pumps also from GE.

The two gas turbines being used for the project include a 7F.05 turbine and a 7F.03 turbine.

The 7F.05 gas turbine will operate on condensate, while the 7F.03 combustion turbine is meant to operate on natural gas, with Arabian Super Light (ASL) crude oil used as the back-up fuel.

Both the GE F-class turbines come with a 14-stage compressor and 3D aerodynamic air foils to increase efficiency, as well as a dry low NOx (DLN) combustion system to control emissions.

Designed to operate at 60Hz frequency, the turbines offer a net combined-cycle efficiency of more than 59%.

Green Duba CSP facility details

The 50MW parabolic trough CSP facility, developed on an approximately 1km² site for the integrated project, is equipped with 48 Ultimate Trough parabolic trough collectors from Flabeg and receiver tubes supplied by Archimede Solar Energy.

Each of the high-performance parabolic mirrors has an aperture width of 7.5m, while the total length of the solar collector tube loop carrying synthetic oil is 800m. The total aperture area for the CSP field is 170,000m².

The solar project involved the installation of a total of 264 double-corrosion protection permanent steel ground anchors each measuring up to 31m-long and the construction of a 1m-thick diaphragm wall (D-wall) comprising 33 panels covering 5,756m².

The solar heat captured by the CSP facility will be used to pre-heat the boiler water that will be introduced into the HRSG, to increase the thermal efficiency of the combined-cycle operation.

Power transmission

The electricity generated by the Duba Green facility will be evacuated via an onsite 380kV/132kV substation into the National grid of Saudi Arabia, which is owned and operated by SEC.

The substation will be connected to the power generation facility through 380kV underground transmission cables.

Contractors involved

Spanish engineering and construction company Initec Energia, along with the local company Saudi Services for Electromechanical Works (SSEM), was awarded the engineering, procurement, and construction (EPC) contract for the integrated solar combined-cycle project in November 2015.

General Electric (GE) received the order to supply key equipment as well as provide long-term maintenance services for the Green Duba combined-cycle plant in January 2015.

Tractebel Engie was appointed as the Owner’s Engineer by SEC for the Green Duba integrated power project.

Flabeg, a high-tech glass and mirrors manufacturer based in Germany, supplied parabolic troughs, while Italian firm Archimede Solar Energy supplied the solar collector tubes for the Green Duba CSP facility.

Schlaich Bergermann Partner (SBP), an engineering and consulting firm based in Germany, was engaged in providing engineering and site services for the parabolic trough facility.

Dextra Group was contracted to supply its Geotec double corrosion protection (DCP) permanent steel ground anchors, while Saudi Bauer was engaged for the equipment installation works on the solar field.

ABB Group was contracted to supply a 420kV gas-insulated switchgear (GIS) for the Green Duba substation in March 2016.