Effective filtration minimizes unplanned downtime, reduces maintenance costs and ensures that the turbines are highly efficient

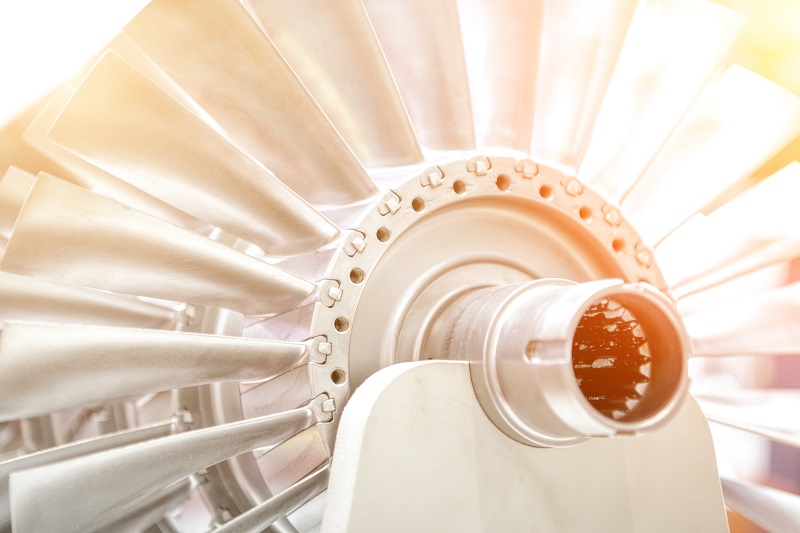

Wheel of the air compressor of an aircraft engine. Replacement of the jet engine.Turbine blades closeup. Shallow depth of field.

Tiny dust particles of a half micrometre size can already lead to severe consequences for the operation as well as the efficiency factor of any gas turbine and turbomachinery. The difference is made between erosion, corrosion and fouling. Thanks optimally designed static filtration concepts risks can be reduced to a minimum.

Erosion, for example, relates to the material removal on the blades through dust particles > 5 μm. These particles have an abrasive effect which influences the aerodynamics of the blades. Fouling is the deposition of particles < 5 μm on the blades which can severely reduce the aerodynamics of any turbine blade.

Even still corrosions inside the turbo machinery are caused by air contaminations – especially through salts in combination with high relative humidity. These aggressive compounds lead to an eventual deterioration of turbine blades.

Installing the right filtration solution or the right combination of filters is extremely significant when protecting valuable turbine blades. Effective filtration minimizes unplanned downtime, reduces maintenance costs and ensures that the turbines are highly efficient.

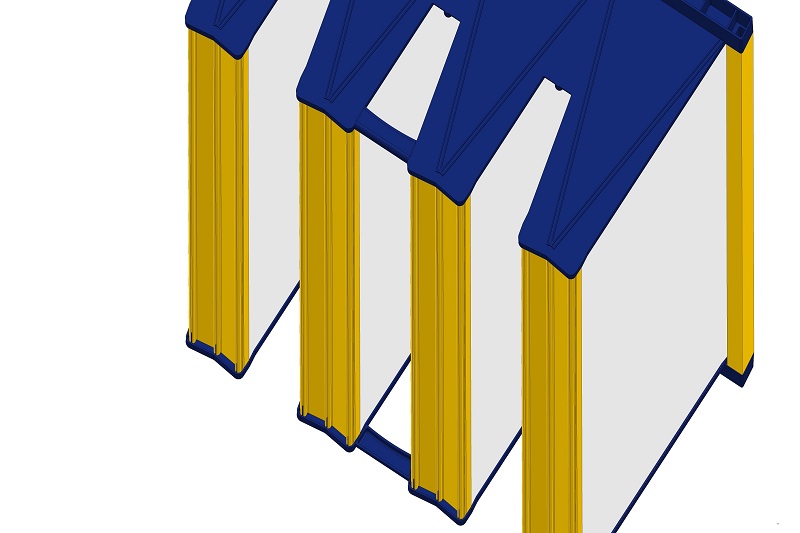

With the redesign of the V-bank, DELBAG has introduced a lighter product that is more sustainable, but still durable. DELBAG have also introduced handles to simplify the transport on-site for maintenance crews during the initial installation process as well as during change-out “session”, where the filters often weigh up to 10 kilos more due to the heavy dust cake accumulated inside the static filter.

The DELBAG engineers have likewise widened the V-arrangement of the four filter compartments, lowering the differential pressure by up to 15% in contrast to comparable products. Still, an additional special feature of the new DELBAG MultiForm V-bank compact filter is its drip trays for excessive condensate at the bottom of the filter compartments, making it perfect for operating in environments of adverse conditions such as fluctuating temperatures and high humidity.

The new V-bank compact filters MultiForm, available in filter classes T5 up to T11, acc. to ISO 29461:1 2021 (former ePM10 to E11), now also comprise practical pre-filter connection clips – making it possible to easily connect various V-banks together and utilize them as a part of an advanced 2-stages or even 3-stages filtration solution.

A multistage filtration set up consisting of pre and main filters ensures optimal performance and protection of any turbine.

Source: Company Press Release