The Norwegian government’s “Longship” project is set to mark the world’s first implementation of a full-scale carbon capture and storage (CCS) programme.

The project, announced in a government white paper on 21 September, has been described as a “milestone” moment in the bid to help Norway meet its climate ambitions and in reaching the goals laid out in the Paris Agreement.

Dubbed Longship after the ships used by Vikings, it will lead to emission cuts, help the development of a new technology and create jobs.

For the $2.7bn initiative, the government has confirmed there will be about $1.8bn worth of public funding put forward.

While Longship will originally be rolled out across the Scandinavian country, Prime Minister Erna Solberg believes that for it to be a successful climate project for the future, other countries also have to start using the technology as well.

Here, NS Energy takes a look at which sites are set to benefit from the project’s implementation.

Initiatives to be funded by Norwegian government’s Longship project

Norcem’s cement factory

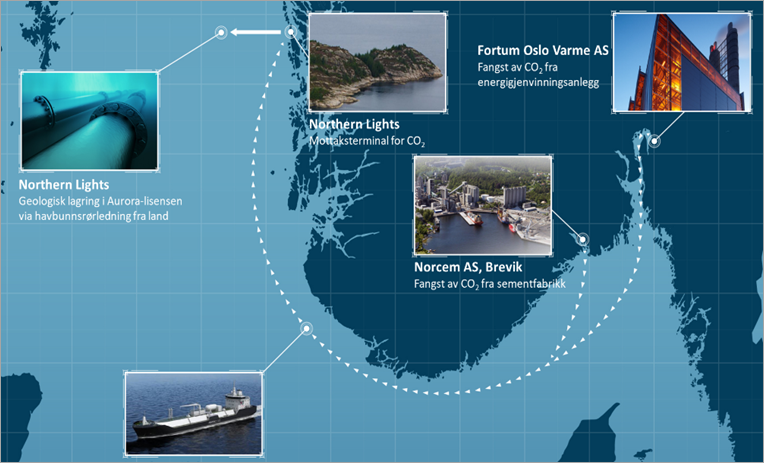

The government has proposed to first implement CCS at Norwegian manufacturer Norcem’s cement factory in Brevik, a small town in south-eastern Norway.

Norcem, which is part of the German HeidelbergCement Group, is aiming to have zero emissions from concrete, seen in a life cycle perspective, by 2030.

It said this ambition will be reached through the development of new types of cement, increasing the percentage of alternative fuels and carbon capture in cement production – which Longship will be aiming to play a key role in.

An essential element in the planned carbon capture is to make use of the residual heat from the cement factory and Norcem claims there is enough residual heat to capture about 400,000 tonnes of CO2 annually – corresponding to about 50% of the plant’s emissions.

It said the CCS facility can be fully operational by 2024 and used at other cement plants around the world.

Fortum Oslo Varme’s waste incineration facility

The government also plans to fund clean energy company Fortum Oslo Varme’s waste incineration facility in the capital city of Oslo.

But speaking at the launch of the International Energy Agency’s CCUS in Clean Energy Transitions report on 24 September, Prime Minister Solberg said Norway will only provide financing for the project if it secures sufficient funding of its own as well as cash from other sources, such as the EU’s Innovation Fund.

The waste-to-energy plant at Klemetsrud incinerates more than 400,000 tonnes of waste per year, which is used to produce electricity, district heating and cooling to Oslo.

Emissions from the plant contain steam and CO2, with flue gas currently being cleaned out of dioxins, nitrogen oxides and carbon monoxide.

Fortum said a pilot for the site demonstrated the possibility to capture 90% of all CO2 in the flue gas, while 58% of the waste incinerated at the plant is of biological origin, making the plant carbon-negative.

Northern Lights project

Longship also comprises funding for the transport and storage project Northern Lights, a joint venture between Norwegian state-owned Equinor, alongside fellow oil majors Shell, a British-Dutch multinational, and French firm Total.

It involves liquefied and pressurized CO2 being loaded from the capture site to the ships which will transport it to the Northern Lights onshore terminal at Naturgassparken in Norway.

At the terminal, CO2 will be offloaded from the ship into onshore intermediate storage tanks.

Buffering the CO2 in onshore intermediate storage tanks allows for continuous transport of carbon by pipeline to the subsea wells for injection into a subsurface, geological storage facility.

The Northern Lights project is set to be developed in two phases, which could see up to five million tonnes of CO2 captured and stored a year.