The Dasa uranium project is an underground, high-grade uranium mine being developed by Global Atomic in the Republic of Niger.

The project was initially envisaged for open-pit operations followed by underground mining after reaching a certain depth with a preliminary economic assessment (PEA) for the open-pit project announced in 2018.

However, Global Atomic concluded that the underground mining operation at Dasa will be profitable after completing various studies.

Global Atomic filed a new NI 43-101 compliant PEA in May 2020 and completed environmental impact statement in July 2020. The Government of Niger issued mining permit in December 2020.

The Dasa uranium mine is expected to produce 4.4 million pounds (Mlbs) of U3O8 a year or up to 48Mlbs of U3O8 over its 12-year phase one operational life.

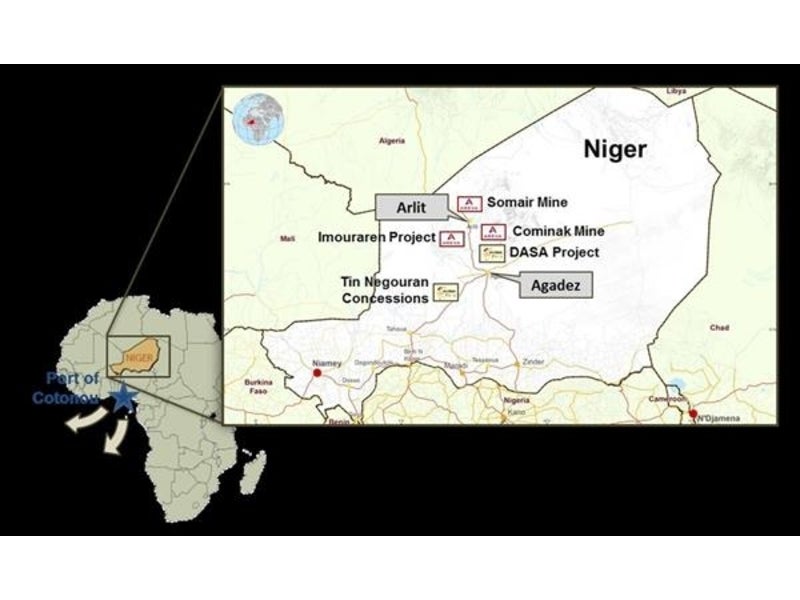

Location and geology

Dasa is a high-grade uranium deposit hosted in sandstone formations inside the Tim Mersoïsedimentary basin. It is located within the Adrar Emoles III permit, approximately 105km south of the Arlit uranium mining town and approximately 120km away from Agadez in Niger. An all-weather road connecting Agadez provides access to the Dasa uranium project area.

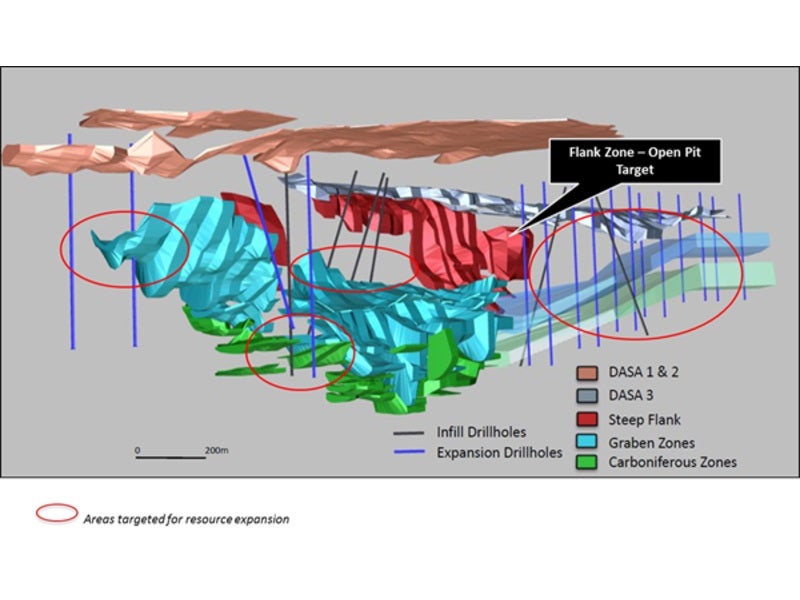

Mineralisation is found in multiple horizons ranging from Jurassic to Carboniferous ages, with Carboniferous sedimentary formations hosting most of the uranium mineralisation. It is associated with a large fault which forms the western edge of graben called the Flank Zone.

Discovered in 2010, the Dasa uranium deposit also has low concentrations of molybdenum and vanadium.

Mineral resources

The indicated resources at the Dasa uranium mine were estimated to be 26.3Mt containing 102Mlbs of uranium, while the inferred resources were estimated at 22.31Mt containing 88Mlbs of uranium, as of July 2019.

Mining operations at the Dasa uranium project

Global Atomic plans to employ the conventional underground mining method using sublevel blast-hole retreat technique with cemented paste backfill. The underground ore can be accessed via the main decline, access ramp, and crosscut drives. The sublevels will be spaced at 20m while the collection drive spacing will be 15m.

The mine will employ standard mechanised underground mining equipment such as advanced ground support drilling rigs and electro-hydraulic face, long- and short-hole drilling rigs. The diesel powered 10t Load Haul Dump (LHD) loaders and 32t underground mine trucks are planned to be used for the material handling purposes.

The ancillary equipment will include diesel-powered charge-up vehicles, utility vehicles, and other light vehicles.

An electro-hydraulic longhole production drill unit is proposed to be used for longhole stoping operations, while a combination of waste rock, classified tailing materials and binding agents will be used to prepare backfill for the depleted stopes.

Broken stock ore at the Dasa uranium deposit will be moved to the run-of-the-mine (ROM) pad crusher feed bin, waste dump storage facility or surface stockpile in 33t haul trucks.

Processing

The processing facility will be designed to process 900,000t of mineralised material per annum to produce approximately 7Mlb U3O8 product in the first six years of production. The processing capacity will be increased to 1.2Mt to produce up to 5Mlb of high-quality uranium ore concentrate from the seventh year.

The Dasa uranium processing plant will feature a crushing circuit with a semi-autogenous grinding (SAG) mill. The slurry will be mixed with sulphuric acid in a series of leach tanks to leach the uranium and then pumped to the resin tanks for the absorption of uranium onto the resin beads.

The uranium will be removed from the resin using sulphuric acid and the final uranium peroxide (UO4) product will be produced using hydrogen peroxide. The final product will then be filtered, dried and packaged for export.