Encana has selected Siemens to provide rotating equipment for the Pipestone Processing Facility, which is being built in Alberta, Canada.

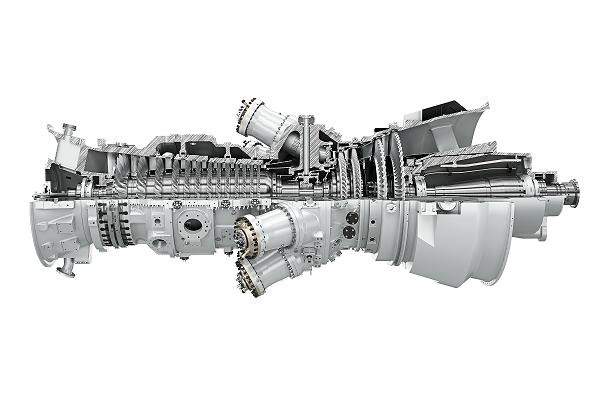

Image: The SGT-750 gas turbine to be used at the Pipestone Processing Facility. Photo: courtesy of Siemens AG.

In this connection, Siemens has been selected by the Canadian natural gas company to deliver a feed and sales gas train and a refrigeration compression train for the Pipestone Processing Facility located in Grand Prairie.

The facility, which will be designed to facilitate capacity expansion in the future, will provide Encana with 19,000 barrels per day of net raw condensate processing capacity along with 170 million cubic feet per day of net inlet natural gas processing capacity.

Keyera will own the facility and provide processing services to Encana. The Pipestone Processing Facility, which will have total processing capacity of 200 million cubic feet per day, is slated to enter into operations in 2021.

The facility’s first train will feature a Siemens SGT-750 gas turbine driving two Dresser-Rand DATUM compressors for feed and sales gas compression. The turbine will be combined with a Siemens waste heat recovery unit for process heat.

The second train will feature a Siemens electric motor-driven DATUM compressor for providing refrigeration compression with Siemens variable frequency drive.

Siemens America Oil & Gas vice president Patrice Laporte said: “Siemens state-of-the-art SGT-750 gas turbine is the only twin-shaft engine in its power class with industry-leading fuel efficiency and one of the lowest emission profiles.

“The train configuration achieved by coupling the SGT-750 with the highly efficient DATUM compressors provides an excellent solution for the Encana’s Pipestone gas compression service.”

According to Siemens, the SGT-750 gives customers a lightweight industrial gas turbine, which incorporates the size and weight benefits of an aeroderivative gas turbine while sustaining the robustness, flexibility, and longevity of conventional heavy-duty industrial gas turbines.

Siemens Oil and Gas new equipment solutions executive vice president Matthew Chinn said: “We’re providing all of the equipment for these two compression trains from one source, which lends testament to Encana’s ongoing confidence in our equipment and Siemens’ capability to offer a one-stop solution to our customers.

“Further to this, our solution is less capital intensive, due to the excellent attributes of the SGT-750 turbine’s lower life cycle costs compared to competing turbines in the industry.”