Predictive maintenance is set to be an “investment priority” for the mining industry over the next two years, according to a report.

The analysis by data and analytics firm GlobalData claims the drive to improve productivity and reduce downtime will lead to further investment by mining companies in predictive maintenance for both plant and mobile equipment.

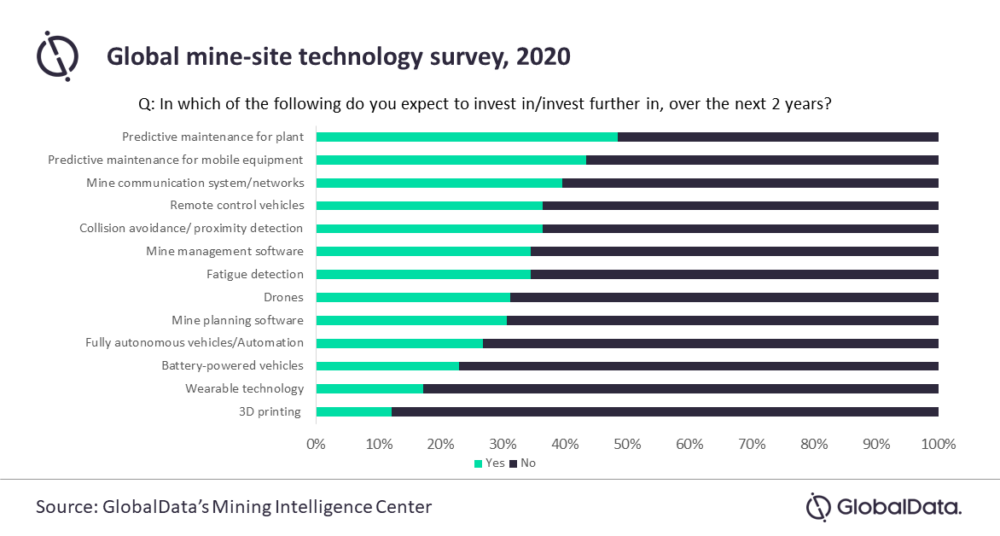

A mine-site survey by the company revealed that, while more than three quarters of mines had already made at least minor investments into predictive maintenance, 48% of miners surveyed expected to either invest in the technology for the first time or invest further in the next two years.

Meanwhile, a further 43% expected to invest in predictive maintenance for mobile machinery across the same period.

Predictive maintenance investment “critical” for mining industry

David Kurtz, director of analysis, mining and construction at GlobalData, believes investment in predictive maintenance is “critical for mines looking to improve productivity and reduce expensive downtime”.

He adds: “The ability of predictive maintenance to collect real-time data from sensors on equipment and use data analytics to detect potential problems before they lead to machine failure not only ensures continued productivity of critical operations, but saves money in parts and labour and can even extend the life of equipment, so the benefits of this technology are considerable.”

GlobalData’s report notes that, across the regions studied, predictive maintenance adoption was highest overall in Australasia – a region that is expected to see the highest levels of investment over the next two years, followed by the Americas.

The most widely adopted technologies were mine planning software, management software and communication systems, with a respective 89%, 86% and 83% of mines having already made at least minor investments in each of these areas.

According to the analysis, the technology that has experienced the highest increase in adoption over the past two years is drones. While 44% of mines had invested to some extent in drones in 2018, this share had risen to 64% by the end of 2020.

Miners have been continuously coming up with various new ways of using drones within the industry, whether it be for exploration, surveying, and mapping to maintaining safety and enhancing security.

The popularity of unmanned aerial vehicles (UAVs) across the mining industry has grown rapidly in recent years, with mine sites across Australasia and Africa showing substantial penetration by drones.

The unlimited aerial data that can be collected with drone technology means engineers can record and track more information in less time, allowing them to focus on analysis and interpretation.

It is believed 70% of the mining majors have at least trialled drones since 2016, with companies such as Rio Tinto, BHP and Anglo American using the technology.