Babcock & Wilcox Nuclear Energy, Inc. and Lightbridge Corporation have signed a memorandum of understanding (MOU) to explore joint development of a pilot-scale facility to demonstrate fabrication of Lightbridge’s metallic uranium-zirconium alloy nuclear fuel.

Babcock & Wilcox Nuclear Energy, Inc. and Lightbridge Corporation have signed a memorandum of understanding (MOU) to explore joint development of a pilot-scale facility to demonstrate fabrication of Lightbridge’s metallic uranium-zirconium alloy nuclear fuel.

Lightbridge’s nuclear fuel technology is designed to provide an increase in power output while simultaneously extending the operating cycle length in existing pressurized water reactors. The metallic fuel could provide improved safety and fuel performance benefits.

The Lightbridge Zr-U alloy is a high-alloy fuel comprised of U-50Zr. One of the primary differences, with respect to irradiation characteristics, of Lightbridge’s metal fuel compared to U-10Zr is a significant reduction in irradiation-induced swelling. The U-10Zr fuels exhibit high radiation-induced swelling (typically, ~30 volume percent within 2 atom percent burnup) while swelling in the Lightbridge metal fuel is expected to be around 1 volume percent per atom percent burnup, the company said on its website.

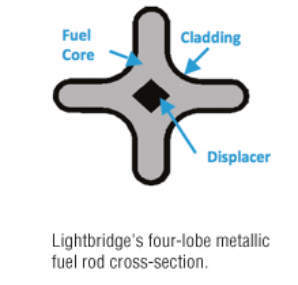

The fuel rod geometry is also innovative: it is not a tube filled wih pellets. It has multiple lobes as seen in cross-section and twists helically along its length. Outer cladding, fuel core and central displacer are bonded during manufacture. Four lobes are used in square lattice designs; three in hexagonal (VVER) lattice designs, according to an article published in Nuclear Technology vol. 180, December 2012, pp437-442 that is posted on Lightbridge’s web site.

B&W NE (a subsidiary of The Babcock & Wilcox Company) and Lightbridge will jointly identify a pilot fabrication facility to demonstrate the fuel rod fabrication capability. If the potential teaming arrangement proves feasible, Lightbridge and B&W could enter into a definitive agreement early next year.

Under the MOU, B&W and Lightbridge agree to perform scoping studies relating to the pilot fabrication facility and explore potential teaming arrangements in that area.

The company plans to start full-scale lead test assembly operation in a PWR by 2017.