There’s a lot of talk — and hype — around the Internet of Things (IoT), but what impact could it have on the nuclear sector?

There is no doubt that the adoption of this technology and the advantages brought by the exploitation of artificial intelligence and blockchain, combined with IoT systems, are increasingly changing the way the industrial and business sectors think and operate.

According to a recent report from the World Economic Forum (WEF), the Industrial IoT is forecast to add $14tn to the global economy by 2030”.

The data gathered by IoT devices, however, is meaningless if it is not analysed and used to inform decisions.

As explained in a paper following the Consumer Technology Association conference CES 2019 exhibition by Sylwia Kechiche, principal analyst at the mobile communications association GSMA, “IoT is meaningless without data and analytics.”

Starting with the issue at hand

Everything originates from an idea, or an issue to solve.

Innovation looks at the best possible solution, optimising the use of existing technologies and identifying the necessary technical readiness levels (TRLs) required.

The solution needs to be studied through its feasibility, its commercial, socio-economic impacts, its strategy and its technical features.

It is an iterative process which uses project management, business and financial analysis, as well as technology evaluation.

Innovation also requires comprehending a global view and the ability to adapt concepts and solutions used in one sector for their implementation in a different context.

Disruptive innovation refers to the disruption of an existing scale of values — a cibceot Clayton Christensen, professor at the Harvard Business School, introduced as early as the mid-1990s.

Current thinkers even believe that the bricks on which the digital technologies are developing, such as computing power and data storage capacity, can amplify this trend in an exponential manner, accelerating innovation.

But adopting innovation is never easy, especially when it comes to established contexts and markets, and innovation implies a change of mentality and discussions about consolidated processes, controls, and regulations.

It is therefore important that innovation occurs in harmony with its environment.

The expression ‘it ain’t broke, don’t fix it’ should not always apply, as even though a system is not broken, it could well be out-dated, or deteriorating, or no longer in line with the changes happening in the direct environment of the system itself.

For instance, in transporting radioactive materials by road, while no change is made to regulations or operations, road traffic may have changed there may be more bicycles or autonomous vehicles, for example, and have an impact on the way roads are used.

According to the UK’s Department for Transport, pedal cycle traffic increased by 28.2% to 2017, which was accompanied by the creation of cycle lanes that could have changed some routes typically used.

How can the IoT improve the nuclear sector?

When discussing innovation, new developments in reactor and fuel design and technology come to mind.

But in power plants operation, decommissioning, transport and storage, there are many areas that could benefit from innovation, ranging from the necessity of updating a business strategy to communication efficiency, maximisation of processes or advanced security.

Of course, each innovation needs to be assessed in terms of safety, security and reliability, ensuring that efficiency of processes is improved while the same levels (or even better levels) of safety and security are assured.

The IoT industry originally focused more on the consumer sector, but it has become apparent during the past two years that IoT brings many benefits to businesses.

New IoT companies are offering new sensor technologies, innovative solutions to each industry sector.

The IoT allows the collection of data, and therefore a better understanding of systems, thei monitoring and sometimes control, which, coupled with AI, can support decision making.

Because of the specific features and needs of the nuclear sector, plants constantly need to be at their optimum degree of maintenance, newer and older plants alike should be monitored and, most importantly, potential failures should be detected as early as possible, in order to intervene promptly regardless of the age of the structure.

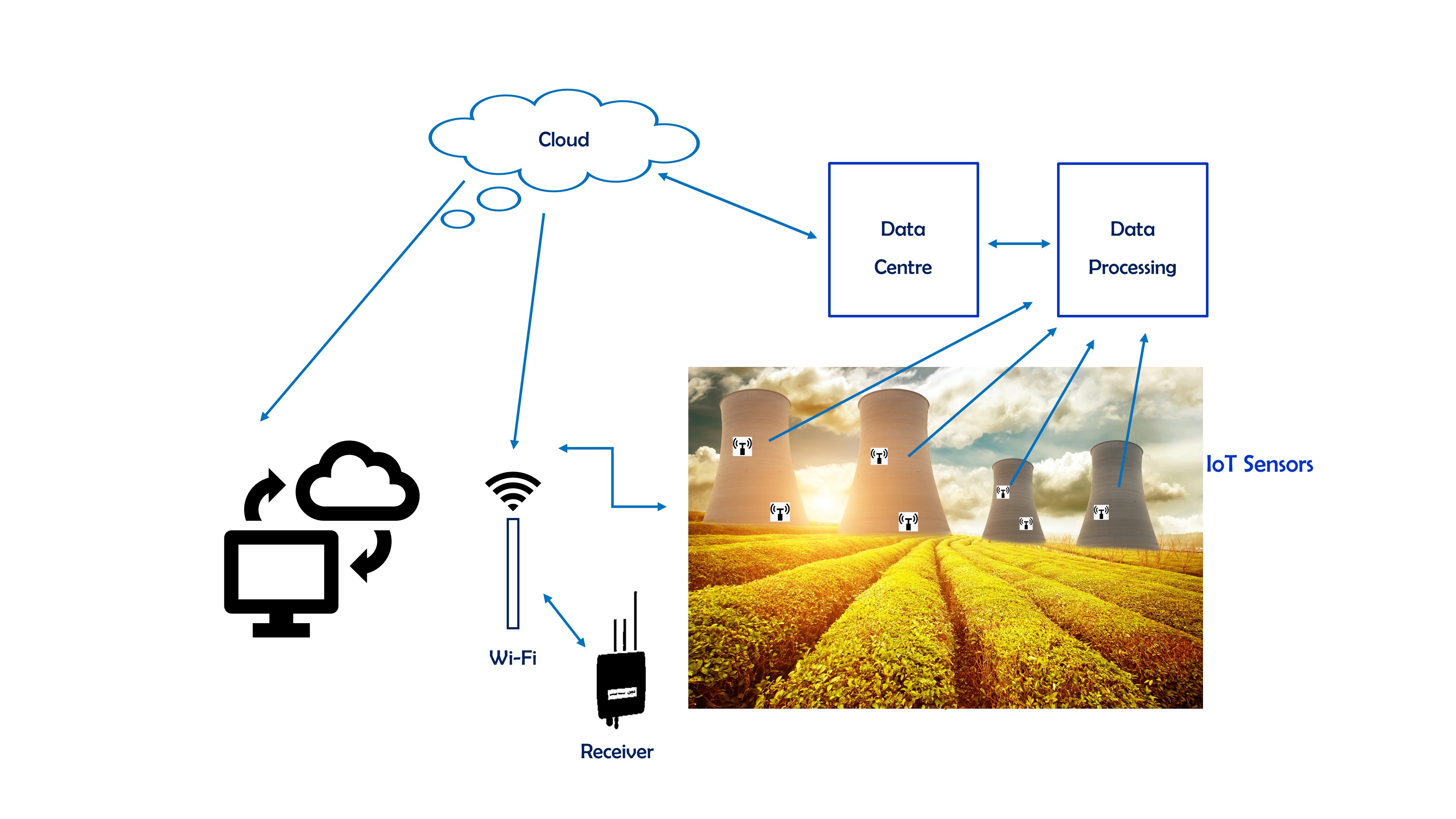

The IoT is available to provide data which will be collected and interpreted to lead to ad hoc actions.

These could then be communicated and exploited for refurbishment, safety and security purposes.

Remote data collection and transmission also allow an increased flexibility to analyse and monitor the plant and its emissions remotely, not to mention the benefit of the automated intervention that IoT allows.

Collecting data, and a well-planned use of these data will be useful to enhance the nuclear sector productivity, safety and durability.

A more refined knowledge of the system should eventually enable a prediction of the performance and assets of a plant.

Navigating risk

As with any innovation, regardless of sector, risks connected to the implementation of IoT technology to nuclear exist — for example, risks relating to the cybersecurity and privacy of data.

These risks are addressed from the system design stage.

Solution robustness and mitigation techniques exist and allow for a strengthened data collection, use the IoT devices, data processing and information transmission to the data centre.

An illustration of an innovative idea transferred to the nuclear from the construction sector is provided by Temlab, a solution ported to the nuclear sector by AB5 Consulting.

It is a newly patented IoT remote monitoring system of concrete corrosion.

The durability and long-term performance of concrete structures in severe environments is severely tested by carbonatation and chlorides.

Traditionally, the monitoring techniques to evaluate any degradation and issues in concrete are carried out by invasive techniques.

The Temlab system, on the contrary, is a non-invasive methodology, based on the measurement of the electrochemical corrosion of embedded steel and of the chlorides concentration and pH via sensors embedded in the structure.

The measurements, especially focused on pH, chloride concentration, conductivity, temperature and humidity measurements, can be taken on site as well as remotely.

The installation of sensors can take place either during concrete casting (the sensors are immersed in the concrete and the reference electrode is placed where the structure solidifies) or in the already solid structure after concrete casting, by inserting them in small holes drilled into the concrete.

While the system has been developed to monitor bridges and buildings, this technology could be beneficial to the nuclear sector as well, providing a safe and cost-efficient solution to monitor concrete structures.

Other benefits include the regular collection of data, which can provide a more continuous control, informing decision-making processes when compared to traditional visual and invasive methods which rely on spot checks.

Compared to other monitoring solutions, the Temlab system is more predictive, as it performs concrete-cover monitoring on any given structure, thus avoiding steel damage.

This is effectively achieved by monitoring chlorides damage in concrete structures and assessing the development stage of carbonatation, both of which constitute the most serious phenomena causing structural degradation.

By exploiting this new technology, the maintenance costs to repair and restore buildings are much lower than those affected by steel corrosion.

Regular monitoring of the structures even before they are affected by corrosion should lower the repair costs.

New technologies are now available and transferred from other sectors, bringing promising opportunities for the nuclear sector.

It is key that the nuclear sector considers and adopts innovative solutions, which will ultimately improve further operations, safety and security, in a cost-effective manner.

This approach needs to be done with a full understanding of the impact on the solution and its environment.