The Vanguard One potash project is located in the Saskatchewan province in Canada. Gensource Potash Corporation plans to develop the project with an estimated investment of $207m.

The bankable feasibility study of the project was completed in May 2017, while environmental approval was received in August 2018. The Vanguard One potash project is expected to produce 250,000 tonnes (t) of potash a year over its 43 years of mine life.

The construction of the project is estimated to take 22 months for completion and create 150 jobs.

Vanguard One potash mine location, geology, and mineralization

Vanguard one potash mine is located in south-central Saskatchewan, neighboring the villages of Tugaske and Eyebrow.

Project Gallery

-

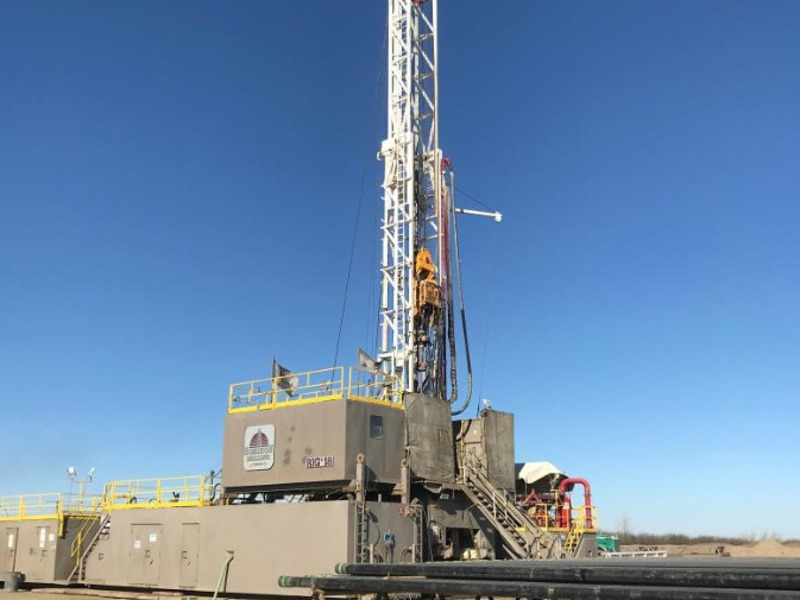

Horizon Drilling conducted the drilling and coring of a new potash exploration well for the project in November 2018. Image courtesy of Gensource.

-

Vanguard One potash project is located in south-central Saskatchewan, near the villages of Tugaske and Eyebrow. Image courtesy of Gensource.

-

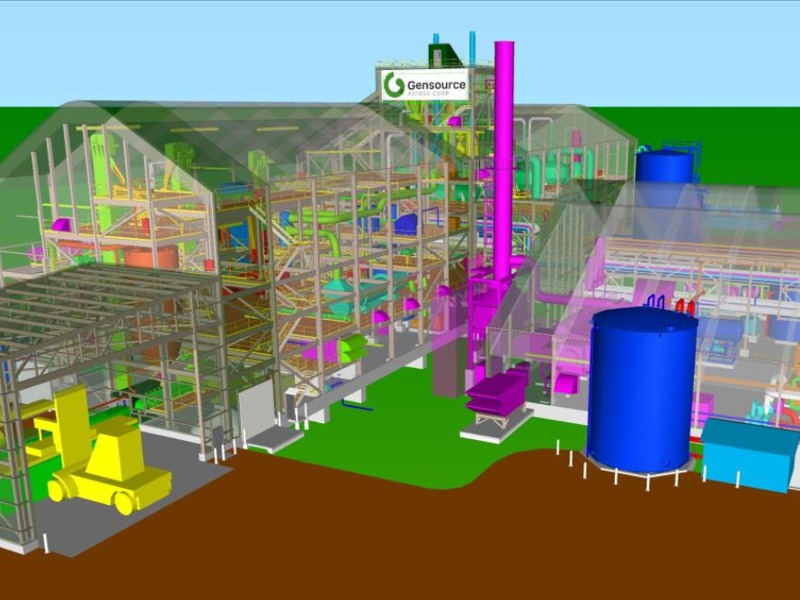

Vanguard One potash project is expected to produce 250,000 tonnes per annum (tpa) of potash. Image courtesy of Gensource.

-

Selective solution mining method will be used for the Vanguard One potash project. Image courtesy of Gensource.

The project geology comprises 500m-thick Laurentide drift in the uppermost section and clastic dominated rocks in the middle portion. The lower sequences consist of sedimentary rocks such as dolomites, limestones, and evaporites of the Precambrian Basement.

The project area lies within the Elk Point Basin that stretches 400km from east-central Alberta to western Manitoba.

Potash mineralization at the project area is primarily found within the Prairie Evaporite Formation, which is dominated by halite, sylvite and carnallite, and sylvite.

Potash reserves at Vanguard One mine

The proven and probable mineral reserves of Vanguard One potash mine are estimated to be 9.79Mt grading 43.44% potassium chloride.

Mining and ore processing at Vanguard One potash mine

Vanguard One will be an underground potash mining operation involving multi-lateral horizontal caverns and employing the selective solution mining technique.

The potash mine is planned to be developed with six solution mining caverns, with each cavern anticipated to produce 45,000t of potash a year.

Mining fleet of the project will include a Mi-Jack Travelift MJ50HDC, Taylor 974 top loader, Taylor 9972 Reach stacker, Komatsu EX50 and BX5 forklifts, a Bobcat 500 skid-steer loader, a Manitex 1704 series boom truck crane, and a JLG E300AJP telescopic handler. The fleet will also include six Ford F-150 gasoline pick-up trucks.

The brine solution consisting of salt (NaCl) and a minor amount of sylvite or potash will be used to dissolve potassium chloride (KCl) in the mining caverns.

The returning potash-rich brine from the mine will be cooled by a vacuum crystallizer, followed by a surface cooling crystallizer operation.

The Potash-containing slurry from the crystallization process will be de-watered in a drum filter prior to being fed a rotary drum dryer.

The obtained solid product will then be compacted, screened, and passed through a dust collection system.

The final product will be loaded into intermodal shipping containers to be railed to the Port of Vancouver (Delta Port) for shipping to the customers in Asia.

The return brine from the processing plant will undergo 100°C heating before being re-injected into the mine caverns for further potash recovery.

Infrastructure facilities

The Vanguard One project site is accessible by the Highways 19, 42, and 367 and the Canadian Pacific rail line.

Water for mining activities will be drawn from four raw water wells located in the north-western part of the project area, while power will be sourced from a transmission line to be constructed as an extension to the existing SaskPower 25kV three-phase overhead line.

The natural gas required for heating operations at the processing plant will be supplied from the TransGas pipeline through a new 150mm-diameter branch pipeline.

Contractors involved

Golder Associates was engaged for environmental, permitting, and social studies for the project.

Credit Suisse Ag Science Team, CIBC World Markets, BMO Capital Markets, CRU were the other consultants engaged in the feasibility study of the project.

AACE International, along with Innovare, South East Construction (SECON), ENGCOMP, and Whiting Equipment Canada prepared the capital cost estimate of the project.