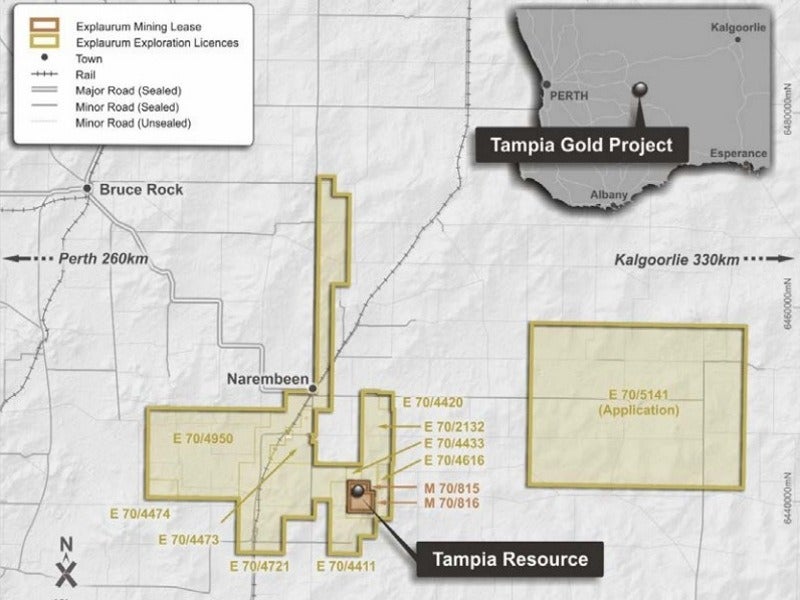

The Tampia gold project is a high-grade gold mine located near the town of Narembeen in Western Australia. Ramelius Resources gained ownership of the project through the takeover of Explaurum Limited in February 2019.

The project is expected to produce approximately 490,000oz of gold over an initial mine life of six years.

Explaurum completed the feasibility study of the Tampia gold project in May 2018. Construction of the project was expected to be commenced by December 2018 and is expected to be completed in the December quarter of 2019. Gold production is expected to be started in early 2020.

Tampia gold mine location, geology, and mineralization

The Tampia gold mine is situated in Lake Grace terrane, approximately 240km from Perth, Western Australia. The Lake Grace terrane comprises metamorphosed to granulite facies within greenstone belt remnants, and granite-intruded banded felsic granulite gneiss.

The Tampia Hill deposits were discovered in 1987 by BHP and subsequently operated and developed by various operators including Dry Creek Mining, Nexus Minerals, Tampia Gold, Auzex Exploration, and Explaurum.

Encompassing an area of 327km², the gold property is made up of two granted mining leases and nine exploration licenses.

The project area hosts a sequence of mafic and felsic granulite facies paragneiss and orthogneiss, with the gold deposit comprising an ovoid-shaped mafic gneiss sequence.

The region is made up of a sequence of late Archean mafic-felsic granulite, facies granitoids, and gneiss intruded all throughout by dolerite dykes of Proterozoic age.

Most of the mineralization is related with tabular zones of intense silicification process and is accompanied by microcline, hornblende and massive, green clinopyroxene.

Tampia gold mine ore reserves

The Tampia gold project is expected to contain probable ore reserves of 7.23Mt, grading 2.09g/t Au. It contains 485,000oz of gold, as of May 2018 estimates.

Mining and ore processing at Tampia gold mine

Conventional open-pit mining, involving drilling and blasting followed by loading and haulage, will be used at the Tampia gold project. Mining is proposed to be conducted in three stages, with initial focus on the southern end of the pit.

Ore will be processed at a 1.5Mtpa processing plant, which features a 420tph capacity crushing circuit. The ore will initially be subject to primary crushing before being forwarded to a single-stage semi-autogenous grinding (SAG) milling comminution circuit.

The grinded material will undergo gravity concentration and leaching in an intensive leach reactor (ILR). The leached product will be taken to a two-stage flotation circuit, wherein the resulting float concentrate will be produced. The concentrate will be pumped to a high-rate flotation concentrate thickener, while the flotation tails will be discharged and pumped into the high-rate pre-leach thickener.

The flotation circuit will recover gold to a low mass sulphide concentrate for ultrafine grinding and enhanced cyanide leaching prior to adsorption in the carbon-in-leach (CIL) circuit.

The CIL circuit consists of a pre-oxygenation tank for flotation concentrate, a leach tank for flotation tails, and six CIL tanks. Gold will be recovered from the carbon loaded product in an elution and electro-winning circuit.

Infrastructure facilities at Tampia gold project

The Tampia gold project is accessed from Perth through the township of Narembeen. Water required by the project is proposed to be sourced from underground sources.

Power supply will be provided by an 8MW LNG-fueled power station located onsite. The power plant will be constructed on a build-own-operate basis, with LNG to be transported by road from Kwinana.

Workers will be accommodated at a 120-person permanent facility, while construction personnel will be accommodated at a 100-person temporary facility.

Contractors involved

Explaurum prepared the updated feasibility study (FS) for the Tampia gold mine in consultation with a number of industry experts such as NPV Consulting, ALS Metallurgy, Metallurgy, Gekko Systems, and JT Metallurgical Services.

Other consultants involved in the FS preparation were Kenex, MineComp, MinEcotech, Mintrex, AMC Consultants, Ecoscape, and MBS Environmental.