The Taichung combined-cycle power plant is a 2.6GW gas-fired facility being developed adjacent to Taiwan’s existing 5.5GW Taichung coal-fired power station, which is one of the world’s biggest thermal power plants.

Taiwan Power Company (TPC), the owner and operator of the Taichung power complex, is implementing the gas-fired project to gradually replace the coal-fired units. The project supports Taiwan’s Renewable Energy Development Act (REDA) energy policy, which aims to increase the gas-fired power ratio to 50% by 2025.

The power station will be initially developed with two combined-cycle units of 1.3GW each. The new high-efficiency, combined-cycle power generating units will be commissioned in phases from 2024 onwards.

The feasibility study of the project was approved by the Executive Yuan in March 2018, while the environmental impact assessment (EIA) was approved by Taiwan’s Environmental Protection Administration (EPA) in January 2020.

Location and site details

The Taichung gas-fired power station will be located in Taichung Port Electric Power Specialised Zone and Industrial Specialised Zone (II) in Longjing District, Taichung City, Taiwan.

It will be developed on a 13.4ha-site adjacent to the Dadu River. The two new combined-cycle units will be installed to the south of the coal-fired units nine and 10 of the Taichung power complex.

Taichung combined-cycle power plant make-up

The Taichung combined-cycle power project will consist of two 1.3GW multi-axis combined-cycle units.

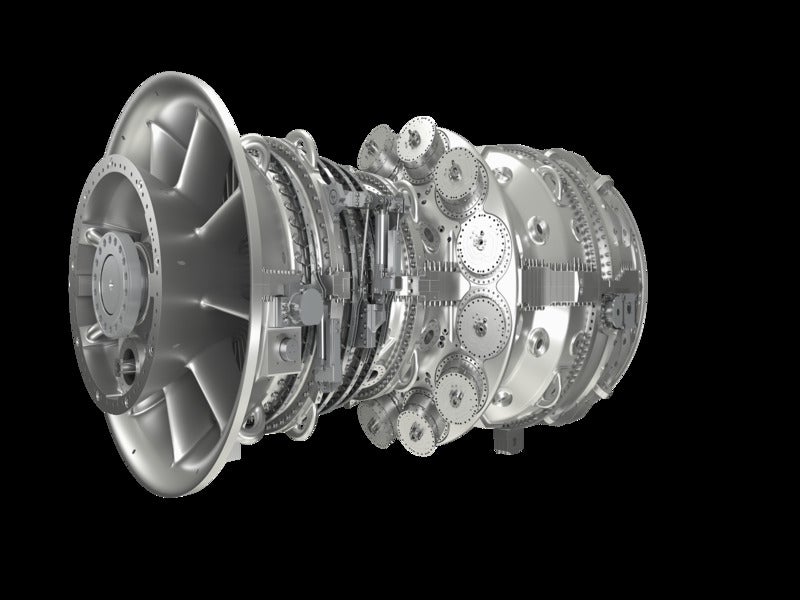

Each unit will be equipped with two 7HA.03 gas turbines and one steam turbine along with supercritical generators and heat recovery steam generators (HRSGs).

The waste heat recovery boiler assembly will include preheater, economiser, evaporator, superheater, steam drum, and feed water pump.

Condensers deployed at the plant will use seawater for cooling. The initial raw water requirement of the gas-fired units is estimated to be 725m³/d.

The plant will also house air pollution prevention facilities, waste storage sites and wastewater treatment plant.

Other infrastructure at the plant will include gas recirculation units, main control buildings, raw water system, fuel supply system, natural gas metering stations, LNG storage tanks, 161kV and 345kV switchyards, circulating water pumps, and associated auxiliary facilities.

Feed gas supply for Taichung gas-fired units

The Taichung combined-cycle power plant will utilise roughly 320 tonnes per hour of natural gas for power generation, which will be supplied from the Taichung liquefied natural gas (LNG) receiving and regasification terminal.

The receiving terminal will have five above-ground LNG storage tanks of 160,000m³ each.

Power evacuation

The power generated from the Taichung gas-fired combined cycle power station will be evacuated to the existing Taipower’s ultra-high voltage power transmission and distribution system, through 345kV overhead power lines.

A 161kV switchyard will be built to provide power supply for the LNG receiving station.

Contractors involved

CTCI and its consortium partner General Electric International (GE) were selected by Taiwan Power Company for engineering, construction, and commissioning of the Taichung combined-cycle power plant as well as the Hsinta combined-cycle power plant in September 2020.

CTCI will be responsible for engineering, civil construction works, erection of power generating units, as well as the balance of plant (BOP) packages.

CTCI will also build the associated receiving terminal, as part of an engineering, procurement, construction and commissioning (EPCC) contract awarded by Taiwan Power Company in September 2020.

GE will supply and install the gas turbines, steam turbines and heat recovery steam generators for the Taichung combined-cycle power plant.

Taichung coal-fired power plant details

The Taichung coal-fired power station comprises ten coal-fired units of 550MW capacity each.

Approximately £2.18bn ($3.34bn) was invested in the construction of coal-fired units one to eight, of which the first four units were commissioned by 1993 followed by the remaining four by 1995.

Units nine and 10 were commissioned in 2005 and 2006, respectively.