The Sheep Mountain uranium project in Wyoming is one of the biggest uranium mining projects in the US. Energy Fuels, a uranium mining company based in the US is the owner and developer of the project.

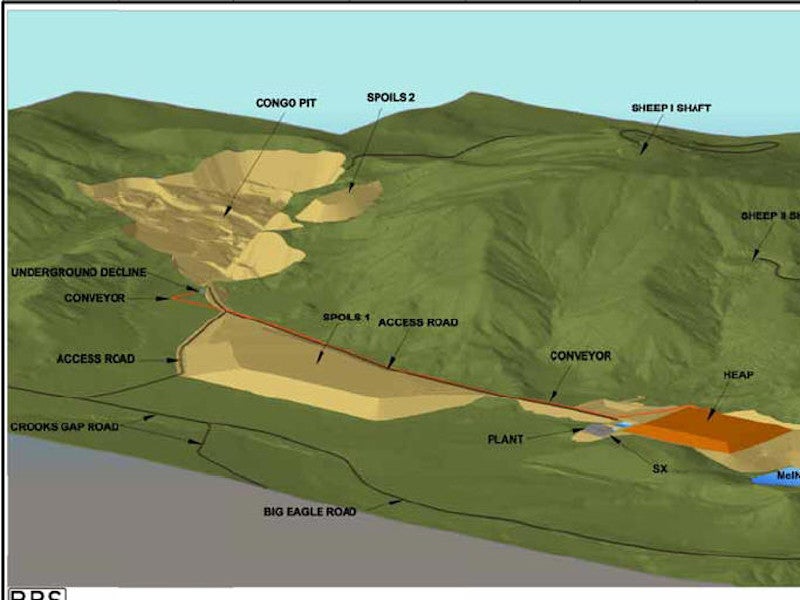

The Sheep Mountain project involves the greenfield development of the Congo open-pit mine, as well as the re-opening of the historical Sheep underground mine.

An updated preliminary feasibility study (PFS) for the project was completed in February 2020. It predicts a total annual production of 1.4 million pounds (Mlb) of uranium over an estimated mine life of 12 years for both the open-pit and underground mines, with an estimated capital expenditure of £124m ($152.6m).

The Sheep Mountain property history

The discovery of uranium in the Sheep Mountain area dates back to the early 1950s. Uranium mining in the area was dominated by Western Nuclear Corporation (WNC), Phelps Dodge (PD) and Continental Uranium Corporation (CUC) until the late 1980s.

USECC, a joint venture of U.S. Energy Corporation and Crested Corporation, acquired the WNC properties in 1988.

Uranium Power Corp. (UPC) acquired a 50% interest in the Sheep Mountain property from USECC in 2007, while the remaining 50% stake was later acquired by Uranium One.

Canada-based Titan Uranium acquired the property ownership from UPC as well as Uranium One in 2009. Energy Fuels acquired Titan Uranium in February 2012 and completed a PFS for the project in April 2012.

Location, geology, and mineralisation

The Sheep Mountain uranium project is located in Fremont County, approximately 13km south of Jeffrey City, at the northern edge of the Great Divide Basin in Wyoming, US.

The Sheep Mountain mining claims cover a total area of approximately 4,475 acres, out of which private lease lands account for 630 acres.

Uranium mineralisation at the deposit is hosted within the Battle Spring Formation of the Eocene Age.

Sheep Mountain uranium reserves

The total probable ore reserves for the Sheep Mountain project are estimated to be 7.4 million tonnes (Mt) containing 18.36Mlb of uranium.

The Congo open-pit is estimated to hold 3.9Mt of probable mineral reserves containing 9.1Mlb of uranium with an average grade of 0.115% U3O8, while the probable mineral reserves of the Sheep underground mine are estimated to be 3.49Mt containing 9.24Mlb of uranium at an average grade of 0.132% U3O8.

The total indicated uranium resources for the project are estimated to be 30.3Mlb.

Mining methods

A combination of underground and open-pit mining methods will be employed for the Sheep Mountain uranium project.

Conventional open-pit mining involving four 637 CAT twin-engine scrapers, four 631 CAT single-engine scrapers, two medium-size excavators, two motor graders, two track- dozers, two 32t articulated trucks, one 980 CAT wheel loader and two water trucks will be carried out for stripping and ore extraction at the Congo pit.

The Congo pit design includes up to 400ft-high walls and a maximum depth of 600ft in the south-east corner of the pit.

Ore extraction from the Sheep underground mine will be carried out through a modified room and pillar method utilising modern mining equipment.

The mining equipment for the underground operation will include five jumbo drills, nine bolters and six scooptrams of seven cubic-yard capacity each.

A 36in conveyor system will be used to haul ore through one of the double declines, while the existing shafts will be used for ventilation purposes.

Ore processing

The conventional heap leach method will be used to recover uranium from the extracted ore.

The run-of-the-mine (ROM) ore will be crushed and stacked in a 40acre heap pad area. The stacked ore material will be treated with acid leaching.

The resultant pregnant leach solution (PLS) will be drained to a collection pond from where it will be pumped to a solvent extraction plant to concentrate and purify the extracted uranium.

The extracted uranium will undergo precipitation for the production of yellowcake products which will be washed, dried and packaged into sealed drums before shipping.

Infrastructure facilities

Primary access to the site is via an existing county road, while telephone, electric and natural gas services are readily available at the site.

The Sheep Mountain uranium project is estimated to require up to 360 gallons per minute (GPM) of process water flow which will be met through the dewatering of the Congo open-pit and the Sheep underground mine.

Contractors involved

BRS Engineering prepared the 2012 PFS, as well as the updated PFS for the Sheep Mountain uranium project which was published in February 2020.