Rook I uranium project is an underground uranium mine located in Saskatchewan, Canada. NexGen Energy fully owns and is developing the uranium deposit at an estimated capital cost of £887m (C$1.5bn).

Pre-feasibility study for the Rook I project with focus on Arrow deposit was completed in November 2018. The deposit is expected to produce 228.4 million pounds (Mlbs) of yellowcake, through a mine life of nine years.

Rook I uranium project location, geology, and mineralisation

The Rook I Project is situated in the north-west of Saskatchewan province, approximately 40km from the Alberta-Saskatchewan border.

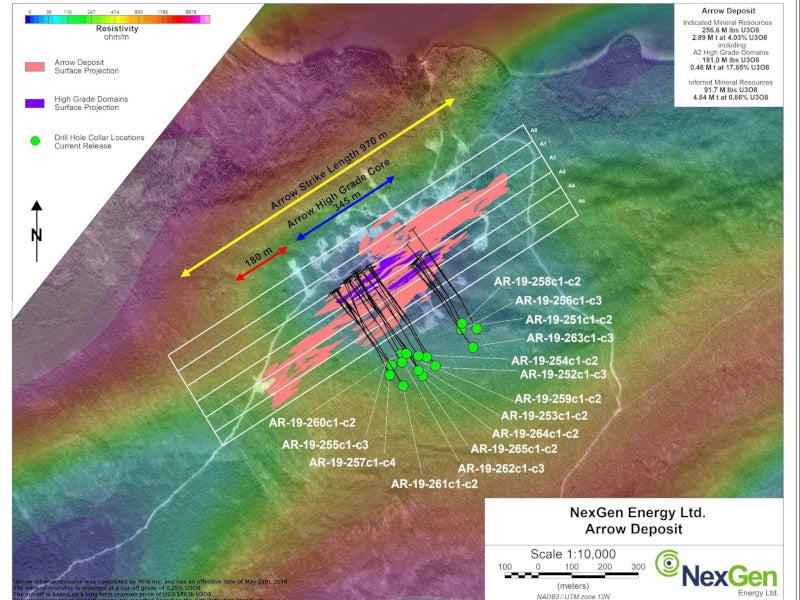

The project comprises the Arrow Deposit, a land-based, basement-hosted deposit that hosts majority of the project resources. The Arrow deposit is currently the biggest development-stage uranium deposit in Canada.

It is located on the south-western rim of the Athabasca Basin, a paleoproterozoic-aged, flat-lying, fluvial and red-based sedimentary basin.

The uranium mineralisation is associated with graphitic, pelitic and graphitic semipelitic gneiss lithologies and occurs within five discrete shear panels. The uranium mineralised lenses and pods, which are oriented parallel and sub-parallel to the regional foliation, are housed in the graphitic shear zones.

Rook I uranium project reserves

The project is estimated to contain reserves of 3.43 million tonnes (Mt), graded at 3.09 % triuranium octoxide (U3O8). It is estimated to contain 234.1 million pounds (Mlbs) of U3O8.

Mining at Rook I uranium project

The Rook I uranium project will employ transverse stope mining and longitudinal retreat stope mining methods for extracting ore.

The Arrow deposit is proposed to be accessed by using two shafts, including a production shaft and a ventilation shaft. The first shaft will be 658m below surface and will also be used to transport personnel and materials into the mine. Sunk to a depth of 533m below surface, the second shaft will be used as an exhaust shaft.

Ore processing at Rook I uranium project

The processing method employs the zero-based design approach, for achieving greater throughput with minimum redundancy, equipment, and design allowances.

The mined ore will be crushed underground and sized to obtain ideal feed for the grinding mill. It will be delivered to the ore feed hopper and weighed on the belt before gamma radiation scan activity to check the uranium content.

The material will be then leached in six mechanically-agitated tanks, with the solution transferred by using gravity. The tanks will have a ten-hour residence time to oxidise and dissolve the uranium, with approximately 99.3% of uranium is expected to dissolved.

The solution will be forwarded to the counter-current decantation (CCD) circuit, which comprises six thickener units operating in the opposite direction. Approximately 99.5% of dissolved uranium will be removed from leach residue solids and the overflow from CCD 1 will be sent to a pin bed clarifier. Overflow from the clarifier will flow to the solvent extraction (SX) feed tank through gravity.

The resultant product will undergo precipitation in a gypsum clarifier and the purified loaded strip from gypsum clarifier overflow will be forwarded to the yellowcake (YC) precipitation tanks.

The YC centrifuge will be washed and conveyed to the calciner, which will be heated by natural gas. The damp uranyl peroxide will be dried and oxidised to produce a U3O8 product.

The Rook I uranium project will employ transverse stope mining and longitudinal retreat stope mining methods for extracting ore.

Infrastructure

The project can be reached through an access road connecting to the existing provincial road 955.

Power supply for the project will be sourced from the on-site natural gas-fired power plant, which features nine generators.

Water required by the project will be collected from Patterson Lake and delivered to a storage tank. The water will be treated in an effluent treatment plant.

The project also proposes to construct a separate water intake, south of the existing camp, to treat the potable water.

Workers will be accommodated at the 500-person accommodation camp, while an airstrip is also available for the transportation of personnel.

Contractors involved

WoodCanada (Wood) and Roscoe Postle Associates (RPA) prepared the technical report of a prefeasibility study for the Arrow uranium deposit.