The Séguéla gold project is an open-pit gold mine being developed by Canadian gold mining company Roxgold in Côte d’Ivoire.

Roxgold announced the completion of a preliminary economic assessment (PEA) for the project in April 2020 and received a 10-year mining permit in December 2020.

The pre-production capital cost is estimated to be approximately £105m ($142m), while the mine life is estimated to be 8.2 years.

The Séguéla open-pit mine is expected to produce an annual average of 143,000 ounces (oz) of gold in the first three years of production and more than 100,000oz per year during the remaining mine life.

Roxgold identified more than 28 highly prospective exploration targets at the time of acquisition of the Séguéla property in April 2019, and the exploration and drilling activities have been underway since then.

Early works including a front-end engineering and design study (FEED) and the upgrading of the site access were commenced in December 2020. A feasibility study is expected to be completed by early 2021 with the start of production targeted for 2022.

Location and geology

The Séguéla gold project is located in the Worodougou Region of the Woroba District in Côte d’Ivoire, approximately 240km northwest of the political capital Yamoussoukro and 480km northwest of the commercial capital Abidjan. The Séguéla property covers an area of approximately 363km2.

The project is situated within the Paleoproterozoic (Birimian) Baoule-Mossi domain of the West African Craton which hosts two cycles of volcanism/sedimentation. It comprises four resource-defined, near-surface deposits namely, Antenna, Agouti, Boulder, and Ancien.

The Antenna deposit is located within a litho-structural domain called the West Domain, which comprises mafic volcanic (basalts) and hypabyssal (sills and dykes) rocks, minor granitoids, rhyolitic lava flows, and volcaniclastic rocks.

The Agouti, Boulder, and Ancien satellite deposits are located in the East Domain that comprises high strain granitoids, orthogneisses, schists, and andesite and basaltic units. The East and West domains are separated by a north-south trending mylonite zone.

Mineralisation and resources

The gold mineralisation at the Boulder and Agouti deposits is related to strongly foliated or mylonitised, quartz/quartz-carbonate veined basalt, and the margins of the felsic intrusive rocks. A brittleductile quartz-albite vein stockwork hosts mineralisation at the orogenic lode Antenna deposit.

The gold mineralisation at the Ancien deposit is related to a brittle-ductile quartz, and quartz-carbonate vein network hosted by intensely sheared tholeiitic basalt.

The project is estimated to contain more than one million ounces (Moz) of measured and indicated mineral resources grading 2.5g/t Au, while the inferred resources are estimated to be 370,000oz grading 4.8g/t Au.

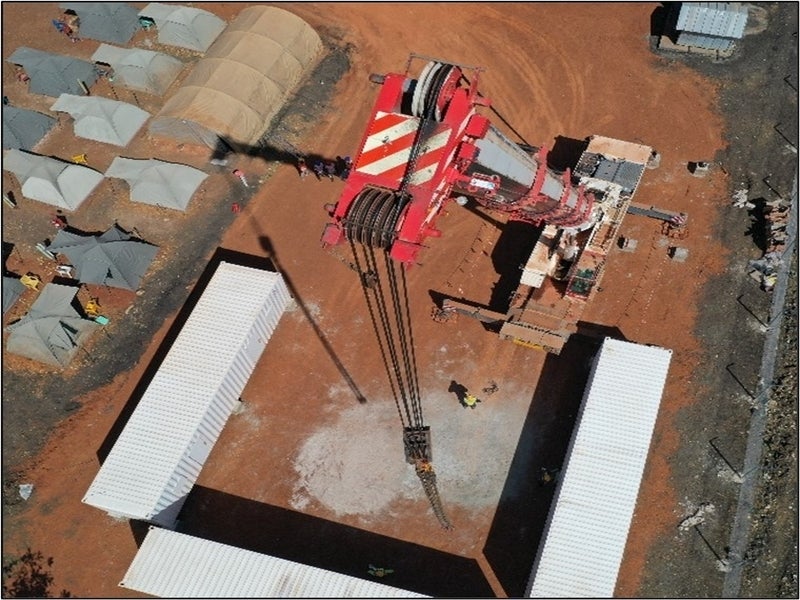

Mining operations

The Séguéla mine will utilise conventional open-pit mining with drill, blast, truck, and loader methods.

The mining fleet will comprise two 125t and two 65t excavators, up to nine Caterpillar 777 trucks, and several smaller articulated trucks to truck and haul the mineralised ore and the waste material.

The run-of-the-mine (ROM) mineralised material will be transported to the ROM pad. The ore material will undergo a single stage primary crush/SAG milling comminution circuit before being conveyed to a surge bin.

Processing

The crushed mineralised material and water will feed the mill that will operate in a closed circuit with hydrocyclones. The gravity gold will be recovered by guiding the cyclone underflow slurry to the gravity circuit.

The gold gravity concentrator tailings will be fed to the cyclone feed hopper and the gravity concentrate will be leached in an intensive leach circuit. The recovery of gold in solution will be achieved with a dedicated electrowinning system.

The recovered gold will be filtered, dried, and will be smelted in a furnace to doré bars.

The processing plant is expected to have a processing capacity of 1.25Mt per year.