The Seagull oil field development project is located in the central North Sea, approximately 230km east of Aberdeen, UK.

Operator Neptune Energy holds a 35% interest in the field which was acquired from Apache Corporation in 2018, while BP holds a 50% stake. The remaining 15% stake is held by Japan Petroleum Exploration (JAPEX) which was acquired from Apache in March 2014.

The project partners reached a final investment decision in March 2019 after the Seagull field development plan was approved by the UK’s Oil and Gas Authority in the same month.

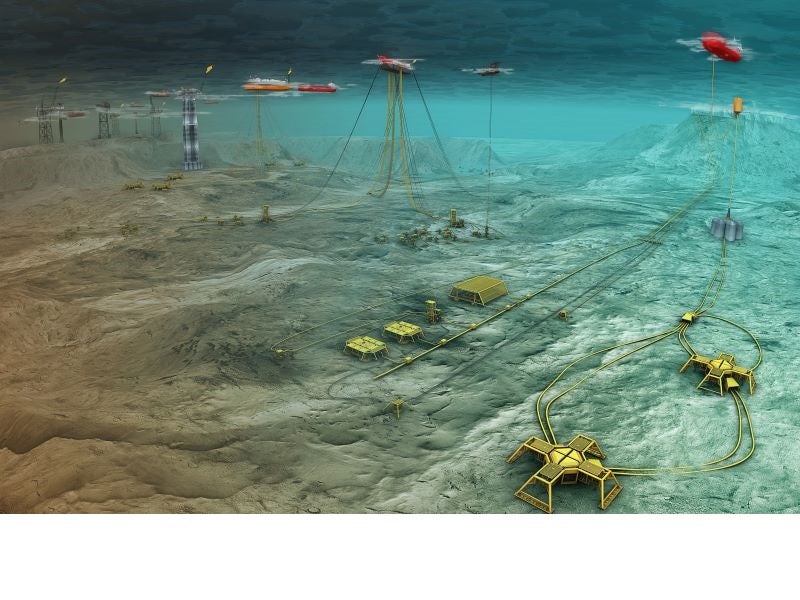

The Seagull offshore field development involves subsea tie-back to the existing facilities of the Eastern Trough Area Project (ETAP).

The subsea construction works for the Seagull project was commenced in September 2020 with the first oil expected in 2022.

The initial production capacity of the project is expected to be approximately 50,000 barrels of oil equivalent a day (boepd) with oil accounting for 80% of the production.

Location and field details

The Seagull offshore project is being developed in Block 22/29C in the Central North Sea, UK, approximately 17km south of the BP-operated ETAP central processing facility. The water depth in the field area is approximately 90m.

Seagull is a high-pressure, high-temperature offshore development project with a reservoir depth of more than 4,000m. The 2P gross reserves of the project are estimated to be approximately 50 million barrels of oil equivalent (Mboe).

Project layout

The Seagull offshore oil field development project involves four production wells and associated subsea structures tied-back to the ETAP central processing facility.

A new 5km-long pipe-in-pipe production line will connect the Seagull development to the Egret manifold, while a 17km-long control umbilical will be laid from ETAP central processing facility to Seagull development.

The well stream from Seagull will flow through the Heron pipeline system to the ETAP central processing facility.

The gas will flow from the ETAP central processing facility through the Central Area Transmission System (CATS) pipeline system to CATS processing terminal in Teeside, UK. The crude oil from ETAP will be transported via the Forties pipeline system to the onshore Kinneil Terminal in Grangemouth, UK.

ETAP

The Eastern Trough Area Project (ETAP) located in the central North Sea consists of multiple fields and a central processing facility that started operations in July 1998. ETAP is expected to continue operations till the mid-late 2030s.

The central processing facility, located in the Marnock field, is operated by BP. The facility consists of a production drilling riser platform and a quarters and utilities platform. Both the platforms are connected by a bridge.

Contracts awarded

TechnipFMC bagged an integrated engineering, procurement, construction, and installation (iEPCI) contract to provide the subsea production system (SPS) as well as the subsea umbilicals, risers, and flowlines (SURF) for the Seagull project in July 2019.

As part of the contract, TechnipFMC will manufacture, deliver and install subsea equipment including wellheads, Xmas trees, an umbilical, flowlines, a four-slot manifold, a subsea wye structure, and a subsea control system.

Valaris was contracted to provide a heavy-duty jack-up drilling rig to drill four wells for the project in September 2019. Rowan Gorilla VI (VALARIS JU-248) will be deployed to drill wells.

Weatherford UK was contracted to provide managed pressure drilling services in July 2020, while Baker Hughes received contracts for coiled tubing & pumping and leak testing services in February 2020.

The Seagull field development partners awarded a bunch of drilling services contracts worth approximately £31m ($40m) for the project in December 2019.

M I Drilling Fluids was contracted to provide mud, drilling fluids, and well-bore clean-up services.

Halliburton Manufacturing & Services was contracted for the provision of high-pressure/high-temperature completions equipment, while Schlumberger Oilfield UK was contracted to provide perforating services.

Vessels used for the Seagull oilfield development

TechnipFMC deployed vessel Normand Mermaid to conduct pre-lay activities including surveying and boulder removal in August 2020.

Apache II pipelay vessel was deployed for laying approximately 5km-long pipe-in-pipe production line from the Seagull development to the Egret manifold, while the Normand Ranger vessel will be used for trenching activities after the pipeline installation.