The 1.28GW Qingyuan pumped storage hydroelectric power plant is located in the Guangdong province of China.

The power plant is owned by CSG Power Generation Company, a group company of China Southern Power Grid. It was developed as part of China’s Eleventh Five-Year Plan and serves as a key energy security project for the Guangdong Province.

The construction of the hydroelectric power station began in December 2009 and installation of equipment commenced in January 2012. The first unit of the power plant commenced operations in November 2015, while the final turbine started commercial operations in August 2016.

Qingyuan power station location and site details

Qingyuan pumped storage hydroelectric power station is located in Taiping town near Qingyuan.

The site lies approximately 20km northwest of Qingyuan in the Qingxin district of Gaungdong province, China. It was chosen due to the good geological conditions, which enabled the excavation and construction of an underground powerhouse.

Qingyuan pumped storage hydroelectric power plant make-up

Qingyuan pumped storage hydroelectric power station includes an upper and lower reservoir with a 500m elevation difference.

The power plant has four generators with a capacity of 356MVA each with a voltage rating of 15.75kV. It has an underground powerhouse measuring 169.5m x 25.5m x 55.7m. The powerhouse comprises of four vertical-shaft single-stage, reversible, mixed-flow Francis turbine units of 320MW capacity each.

Each turbine unit has a pumping head in the range of 470m and 509.08m.The maximum continuous rating (MCR) of each turbine is 326.5MW.

The turbine units employ splitter runners consisting of long and short blades placed alternatively as compared to conventional type runners. The splitter runner component increases the stability and performance of the power station by reducing pressure fluctuations and vibrations during partial load operation.

The powerhouse also includes a main control room, auxiliary workshop and installation field. It has a total of 16 openings in the underpass.

A water conduit system was established to distribute water into four units for both upstream and downstream section of the system without involving upstream surge tank.

Qingyuan pumped storage power station operation

The Qingyuan pumped storage power station generates electricity by shifting water between the upper and lower reservoirs. It serves as an emergency back-up for China Southern Power Grid and helps in peak shaving, valley filling, and frequency modulation.

During periods of low demand, water from the lower reservoir is pumped into the upper reservoir and stored. The water from the upper reservoir is released through a penstock that drives the 320MW Francis turbines during peak demand.

Contractors involved

Gaungdong Hydropower Planning and Design Institute was responsible for the design and construction of the power plant.

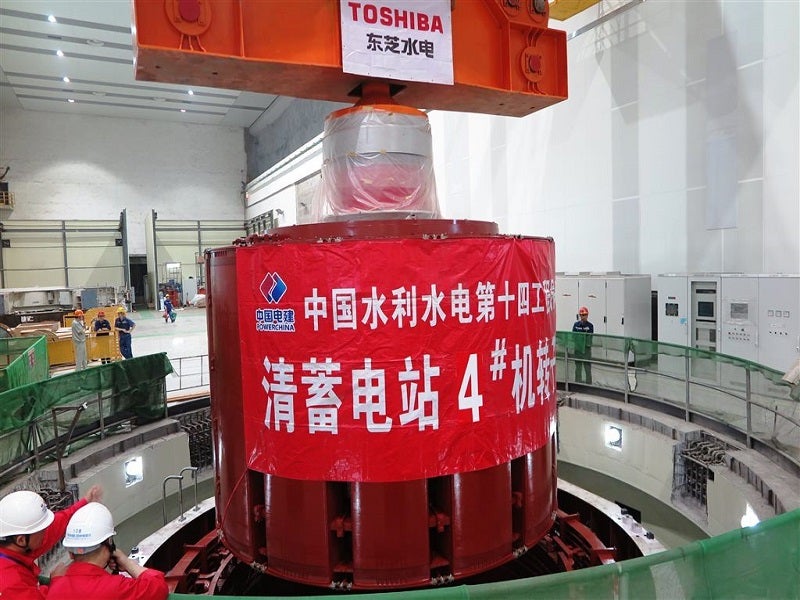

Toshiba Hydro Power (Hangzhou) Corporation (THPC), a joint venture of Toshiba and Sinohydro Corporation of China, was awarded a contract by CSG Power Generation Company in May 2010 for supply of pumped-turbines, generator-motors and ancillary equipment.

THPC supplied the balance of plant (BOP) systems including supervisory control systems, protection systems, speed governors, and excitation systems. It also supplied electromechanical systems such as static starter, main circuit equipment, switchgears, station service power supply systems, and emergency diesel generation systems.

Additional equipment supplied include draft gate systems, water supply systems, oil pressure systems, compressed air systems, and valves and piping.

Bentley Systems’ software was used to develop a 3D model of the hydroelectric power station. The software enabled optimisation of the design process and improvement of project quality during the construction phase. The 3D modelling also guided and executed the complex underground cable network of the project.