The Port of Rotterdam CO2 transport hub and offshore storage (Porthos) project is an innovative carbon capture utilisation and storage (CCUS) project being prepared near Europe’s biggest port Rotterdam in South Holland, Netherlands.

It is proposed to be developed as an open-access project to capture, transport, and store the CO2 produced from refineries, chemical, and hydrogen plants in the Port of Rotterdam area in empty gas fields in the North Sea. The Rotterdam port region accounts for approximately 16% of the total CO2 emissions in the Netherlands.

The £450 (€500m) Porthos CCUS project is proposed to developed through a joint venture partnership between three state-owned companies, including Energie Beheer Nederland (EBN), Gasunie, and the Port of Rotterdam Authority.

Expected to commence operations in 2023, the Porthos CCUS project will be capable of storing approximately 2.5 million tonnes (Mt) of CO2 a year.

Rotterdam CCS project development

A feasibility study for the carbon capture and storage project was completed in April 2018, while the front end engineering and design (FEED) studies were started in the first half of 2019 and the project was awarded Connecting Europe Facility (CEF) subsidy by the European Commission in July 2019.

The Porthos joint venture signed an agreement with four oil and gas, and chemical companies for preparing for the CO2 capture, transport, and storage as part of the project in December 2019.

The environmental impact assessment (EIA) for the project is expected to be completed in September 2020, while a final investment decision is expected in 2021 with the start of construction expected in 2022.

Porthos was recognized as a “Project of Common Interest (PCI)” by the European Union (EU) in February 2020.

Porthos project make-up

The interested refineries and chemical companies will capture CO2 at their facilities and transport the same through a collective pipeline which will run onshore in the Rotterdam port area for a total distance of 32km. The operating pressure and temperature of the onshore pipeline will be up to 40 bar 15°C respectively.

The CO2 will then be pressurised to 132 bar and transported through a 19km-long offshore pipeline to a platform in the North Sea. The operating temperature of the offshore pipeline will be up to 80°C and it will be buried approximately 10m-deep beneath the seabed.

The CO2 received at the offshore platform will be pumped into the sealed reservoirs of empty gas fields located approximately 3km below the seabed. The maximum CO2 storage capacity of these reservoirs is estimated to be approximately 37Mt.

The project will involve a compressor station to be built on a 16ha-site on Maasvlakte, which is the westward extension of the Europoort port facility within the Port of Rotterdam.

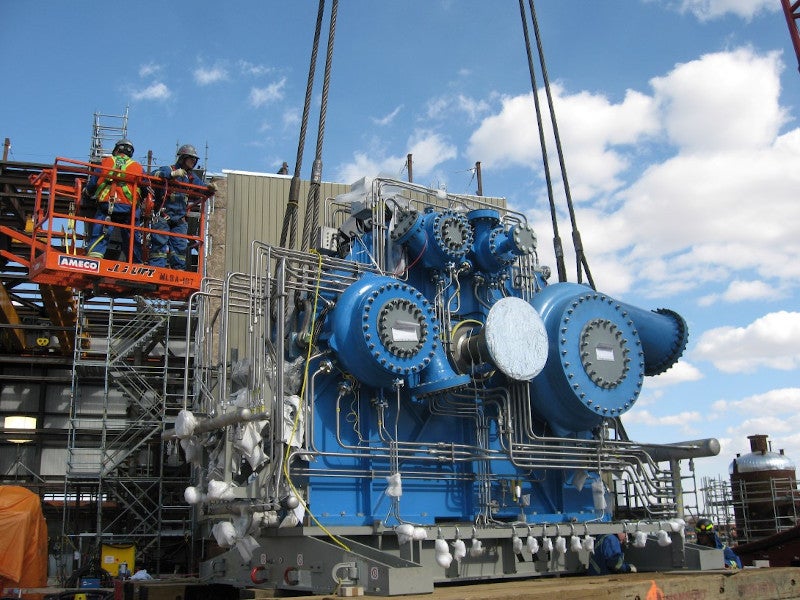

The compressor station will initially comprise three compressor trains capable of handling 258t of CO2 per hour with three additional units planned to be added in the future.

Project partners and contractors

Porthos signed an agreement with ExxonMobil, Shell, Air Liquide and Air Products for preparatory works for capturing and transporting the CO2 from their refineries and hydrogen-producing facilities at Rotterdam as part of the Porthos CCUS project in December 2019.

Germany-based MAN Energy Solutions was contracted to supply three compressor trains, including two RG 25-4 and one RG 31-4 type compressor trains for the compressor station of the Porthos project in May 2020.

Future plan

Although the first phase of the Porthos CCS project involves the capture and storage of CO2 from companies in Rotterdam, it has also the potential to provide the carbon storage solution to the industry in Antwerp, Ghent, Terneuzen and Vlissingen in a subsequent phase.