The Dewey Burdock uranium project is a high grade uranium project located in South Dakota, USA. The project is fully owned and operated by Azarga Uranium.

The uranium project was issued the final supplemental environment impact statement (SEIS) by the Nuclear Regulatory Commission (NRC) in the first quarter of 2014.

A preliminary economic assessment (PEA) of the project was released in January 2020. Azarga Uranium is currently in the process of obtaining regulatory permits to commence construction of the project.

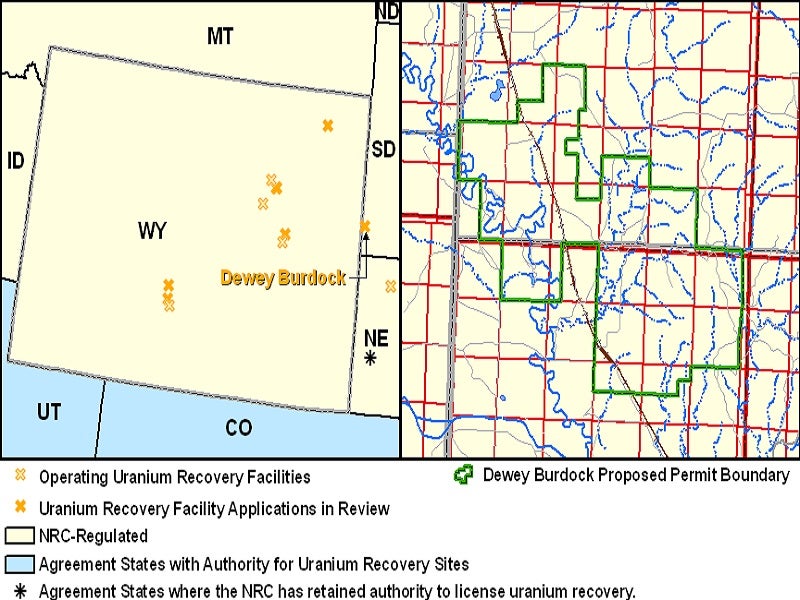

Dewey Burdock uranium project location and geology

The Dewey Burdock uranium project is located in the Edgemont uranium district, in South Dakota, USA. The project covers a surface area of approximately 12,613 acres and 16,960 net mineral acres.

The project is divided into Dewey and Burdock resource areas. The Dewey resource area comprises of approximately 73 surface acres and 32 well fields, while the Burdock resource area includes 93 surface acres and 19 well fields, where mineral extraction will occur.

Geology and mineralisation

The Dewey Burdock deposit consists of permeable sandstone deposits of the Fall River and Lakota Formations of the lower Cretaceous age.

The Lakota formation consists of point bar and transverse bar deposition sediments with typical stream channel systems of meandering fluvial deposition. The Fall River channels sands are noticeably thinner with superimposed marine sediments on the fluvial sands.

The uranium mineralisation at the deposit occurs in sandstone packages within the Inyan Kara Group of the Fall River Formation and the Chilson Member of the Lakota Formation.

Dewey Burdock uranium project resources

As of January 2020, the measured resources of the Dewey Burdock uranium project are estimated at 5.42 million tonnes (Mt) grading 0.132% U3O8.

The indicated resources are estimated at 1.96Mt grading 0.072% of U3O8 and inferred resources are 645,546 tonnes grading 0.055% of U3O8.

Mining methods at Dewey Burdock Uranium Project

The Dewey Burdock uranium project will utilise in-situ recovery (ISR) method to mine the uranium.

The production well fields will be developed based on conventional five-spot patterns with injection and production wells at an interval of one mineralised zone at a time to isolate the screened uranium-bearing interval.

Each injection and production well will be connected to their respective injection or production manifold in a header house. The header house will distribute barren lixiviant solution to injection wells and collect pregnant lixiviant from recovery wells. Each header house will be connected to two production and two restoration trunk lines as required.

The ISR process will involve the dissolution of uranium compound from the host using the barren lixiviant solution, which contains dissolved oxygen and carbon dioxide. The uranium-rich solution will be pumped through the recovery wells to the nearby satellite facility developed in the Dewey resource area.

The water recovered from the mineralised zone will be injected into deep disposal wells (DDW) after treatment for radionuclide removal.

Mineral processing

The project’s central processing facility (CPP) will be located at the Burdock resource area. It will feature a uranium recovery/extraction circuit (IX), an elution circuit, a yellowcake precipitation circuit and a dewatering, drying and packaging circuit.

The satellite facility will be installed with anion exchange (IX) and resin transfer systems to provide loaded resin to the CPP for removal of uranium from the resin and further processing. The CPP will have four pressurised IX trains at full production capacity for a combined production capacity of one million pounds (mlb) of U3O8 per year.

Each IX train is designed to contain 500 cubic foot batch of anionic ion exchange resin, configured in parallel trains of two columns operating in a series. The loading mechanism will utilise a pressurised down-flow methodology.

The loaded resin from the IX circuit is transferred to the elution circuit for uranium stripping using a mixture of sodium chloride and sodium carbonate. The barren resin is rinsed and returned to the IX circuit.

The rich eluate solution from elution circuit is mixed with sulfuric acid in the precipitate circuit to break down the uranyl carbonate and liberate carbon dioxide, leaving free uranyl ions. After precipitation, the uranium precipitate slurry is pumped to a thickener to produce the uranium precipitate or yellowcake.

The yellowcake is then removed for washing, filtering and then drying in a low temperature vacuum dryer and packaged into 55 gallon drums for storage and transportation to a conversion facility.

Project infrastructure

A public access road, approximately 1.4km north-west from Burdock to the west from Fall River County Road 6463 allows access to the western portion of the Dewey Burdock project. All other portions of the project can be accessed via private ranch roads.

Power required for the project is anticipated to be provided by The Black Hills Electric Cooperative via a substation located in Edgemont, South Dakota. Power will be transmitted by overhead distribution lines from the substation to medium voltage transformers located near the central processing plant and satellite sites.

The nearest accessible domestic water supply is approximately 3,000ft below the surface in the Madison Formation. Two water wells will pump water to the plant for storage in either the utility water tank or the domestic water tank. The utility water tank will provide water for plant processing circuits and the domestic water tank will provide water for domestic uses.