The Cinovec lithium-tin project is a high-grade underground deposit located in Prague, Czech Republic. It is the biggest lithium deposit in Europe and one of the biggest tin resources being developed in the world.

European Metals Holdings fully owns the project and is also developing it with an investment of £383m ($482m).

Pre-feasibility study for the Cinovec lithium-tin project was completed in April 2017. The average rate of production at the project will be 1.68 million tons per annum (Mtpa), through its anticipated mine life of 21 years.

Cinovec lithium-tin project location, geology, and mineralisation

The Cinovec lithium-tin project is situated approximately 100km to the north-west of Czech Republic’s capital Prague, on the German border.

The deposit is associated with the Cinovec Zinnwald granite cupola and comprises irregular metasomatic greisen, which hosts quartz, zinnwaldite, fluorite, and adularia-K feldspar.

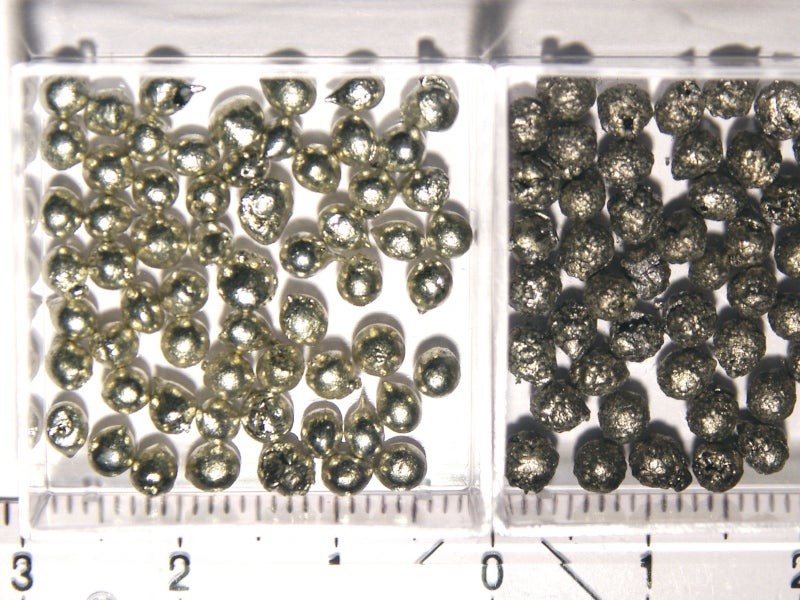

The thin and flat greisen zones enclosing quartz veins that are up to 2m-thick are part of the Cinovec deposit. The minerals contained in the deposit are cassiterite, scheelite, zinnwaldite, and wolframite.

Cinovec lithium-tin project reserves

The Cinovec lithium-tin project is expected to contain probable ore reserves of 34.5Mt graded at 0.65% Li2O and 0.09% Sn.

The indicated and inferred resources are estimated to be 695.9Mt, graded at 0.195% Li. Contained reserves are estimated to be seven million tonnes (Mt) of lithium carbonate-equivalent (LCE), 101,635t of tungsten, and 278,360t of tin.

Mining at Cinovec lithium-tin project

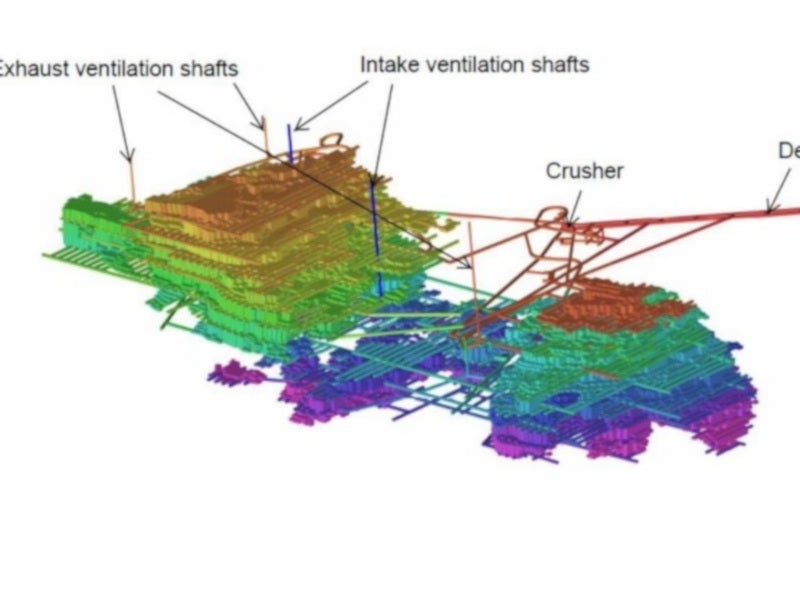

The mining method proposed to be used at the Cinovec lithium-tin project is long hole open stoping method. The ore body of the underground deposit is flat or shallow-dipping and will be mined with pillars support in addition to cement paste back-fill.

The mine will be accessed by two declines, with the first one comprising a conveyor to transport the material from the underground primary crusher to surface. The second decline will be used as a service decline for mineworkers, material, and as an intake airway.

Processing at Cinovec lithium-tin project

The Cinovec lithium-tin project is expected to provide 360,000 tonnes per annum (tpa) of mica concentrate to the lithium carbonate and hydroxide plants (LPP).

The processing plant will use a two-stage crushing plant, and screened in a double-deck vibratory screen.

The run-of-mine (ROM) ore will then be passed through a comminution plant for resizing to a particle size distribution (PSD) ideal for lithium recovery.

The product will be then conveyed to the beneficiation plant, which will produce lithium-rich magnetic stream (mica-concentrate) through the separation of paramagnetic zinnwaldite. It will also treat the non-magnetics by-product stream using gravity, flotation, magnetic, and electrostatic separation processes to produce tin and tungsten product.

The concentrate will be mixed with limestone, waste gypsum, and recycled sodium sulphate before roasting to convert the lithium into a lithium potassium sulphate. The product will be then leached to dissolve the contained lithium sulphate values.

Crude lithium carbonate is then precipitated from the purified leach solution through alum precipitation.

The beneficiation plant will also treat the non-magnetics by-product stream with gravity, flotation, magnetic, and electrostatic separation to produce tin and tungsten product.

Potassium sulphate, which is produced as a by-product, will be dried and packed for sale. The battery-grade lithium carbonate will be further processed to produce battery-grade lithium hydroxide.

Infrastructure facilities

The Cinovec lithium-tin project can be accessed through both road and rail. It is located near industrial and chemical plants with support services in Czech and Germany.

The site infrastructure includes a 22kV transmission line, and a well established water and communications network.

Underground infrastructure facilities will include mine service water systems, electrical reticulation system, control systems and instrumentation, trackless workshops, and underground crushers, tips, and conveyors.

Contractors involved

European Metals prepared the project PFS with support from independent consultants such as Widenbar and Associates, Bara Consulting, Ausenco, and Hatch Associates.