The switchgear with a capacity of 72.5kV has been installed at wind farm, which is being built by Siemens Gamesa Renewable Energy, to protect the wind turbines from overloads and short circuits and ensure an uninterruptible power supply.

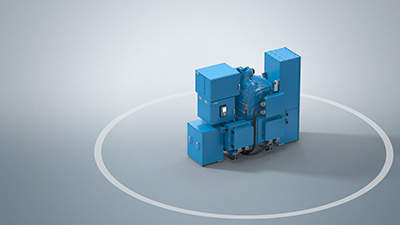

Siemens said that the metal-encapsulated 8VM1 from the blue GIS portfolio has been developed specifically for use in offshore wind turbines.

The new switchgear does not require SF6, instead, uses clean air as the insulating medium.

For the wind project, the operators Nissum Bredning Vindmøllelaug and Jysk Energ are using new cable and turbine concept at a voltage of 66kV to connect the four units of 7MW wind turbines from Siemens to the grid.

Siemens said in a statement: “Compared with the usual 33kV grid connection, this new concept increases transmission capacity and lowers the cost of laying cables.”

The wind farm has commenced electricity generation since March 2018.

The firm noted that the 8VM1 blue GIS is an enhancement of the switchgear that use SF6 as the insulating, switching, and extinguishing gas.

Siemens Energy Management Division High Voltage Products Business Unit CEO Karlheinz Kronen said: “We’re proud that our new SF6-free switchgear are being used successfully in the Nissum Bredning Vind wind farm.

“We’ve constructed the 8VM1 specifically for this type of deployment and focused on an environmentally compatible design during development. Customers will therefore benefit from the advantages of our proven vacuum switching technology with no SF6.”

According to the company, the economic prospects of the offshore wind energy technology being tested in the project are expected to show a major positive impact on the costs for power generation.

The Danish energy agency DEA expects the components being tested in Nissum Bredning to help in saving investment and operating costs.