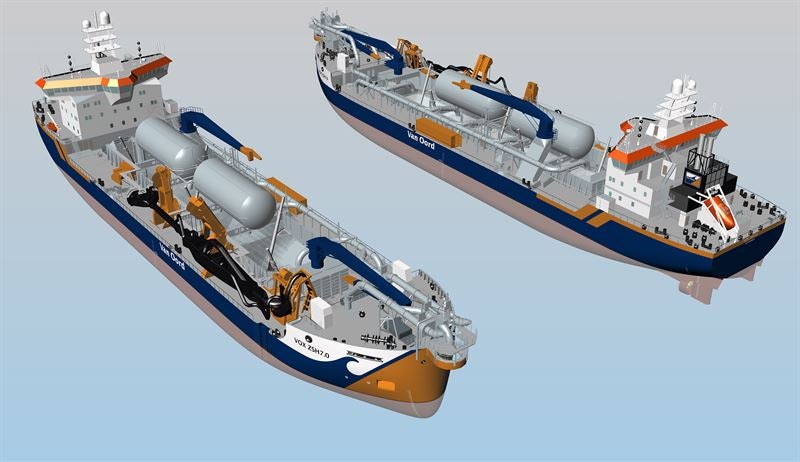

The technology group Wärtsilä will supply a unique and patent-pending LNG fuel storage and supply system for two new trailing suction hopper dredgers (TSHDs). The ships are being built by Keppel Offshore & Marine for Van Oord, the Dutch marine contractor. The order with Wärtsilä was placed in Q2 2019.

The Wärtsilä system comprises two 640m3 single-shell polyurethane insulated storage tanks, featuring a new and innovative ‘In Line Tank Connection Space (ILTCS)’ that contains the process equipment. This LNGPac-ILTCS has the process equipment mounted in front of the tanks, instead of the usual on top installation. For on-deck applications this significantly benefits the vessel’s view lines for better navigational safety, while also reducing the risk of damage to equipment that is typically installed on top of a single-shell tank. Furthermore for below deck installation, the ILTCS improves fuel storage volume efficiency by avoiding the need to have the process equipment on top of the tank, which simplifies installation of the LNG system.

“Our experience in the marine industry’s LNG fuel gas market is unmatched, and this latest development of the famous Wärtsilä LNGPac fuel storage, supply and control system reflects this knowledge and experience,” says Antti Kuokkanen, Vice President, Electronics, Entertainment and Processing, Wärtsilä Marine.

“We are very pleased to collaborate with Wärtsilä, a globally recognised leader in LNG fuel systems, for this project. Thanks to this unique technology we’ll be gaining more experience using LNG as an alternative fuel in our dredging fleet,” says Jaap de Jong, Director Ship Management Department, Van Oord.

The Wärtsilä equipment is scheduled for delivery to the yard in mid-2020 for the first vessel, and in autumn 2020 for the second one