Brixton Metals has discovered diamond bearing kimberlite at Langis project located in Ontario, Canada.

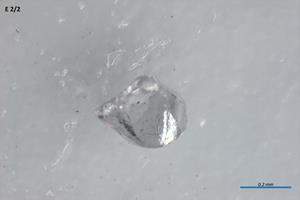

Image: Image of the diamond recovered at the Langis Project. Photo: courtesy of Brixton Metals Corporation.

The Company sent a total of 53.6 kg collected from the three holes that intersected the kimberlitic rock to SRC Geoanalytical Laboratories Diamond Services (GLDS) in Saskatoon for micro diamonds recovery tests. Micro diamonds recovery tests returned one diamond from the kimberlite intersected in drill hole LM-18-37.

Chairman and CEO of Brixton, Gary R. Thompson stated, “We are very intrigued by this discovery. We were targeting cobalt-nickel-silver mineralization in the shallow Archean rocks when we encountered the kimberlitic material. The fact that we recovered a diamond fragment given that the kimberlite sample size was very small is an exciting discovery. The kimberlite in hole 36 to hole 37 is 149m apart and the distance of the kimberlite from hole 37 to the kimberlite in hole 34 is 515m. This has piqued our interest as to whether a very large kimberlite pipe or a series of pipes exists.”

Three holes encountered kimberlitic breccia directly beneath the overburden (22m to 40m vertical depth). Please see figure 2.

Generally the kimberlitic rock is heavily weathered and brecciated. Additional work to determine the heavy minerals content and petrography is ongoing.

The first kimberlite unit was discovered in drill hole LM-18-34. Hole 34 was drilled at 130 degrees azimuth with a dip of 38 degrees. Overburden was encountered to 65m drill depth of approximately 40m vertical depth. The kimberlite in hole 34 is a 15m interval from 65m drill depth. The kimberlite is very weathered including limestone rich fragments.

Drill hole LM-18-36 is located 495m to the northeast from hole 34. Drill hole LM-18-36 was drilled at 120 degrees azimuth and a 38 degrees dip. Overburden was encountered to 36.5m or about 22m vertical depth. The syenite clast rich kimberlite was encountered over a 14m interval from 36.5m.

Hole LM-18-37 was located 149m northwest from drill hole 36 and 515m from hole 34. Hole 37 was drilled at 351.5 degrees azimuth and a 38 degrees dip. Overburden was encountered to 57m or about 35m vertical depth. The kimberlite interval in hole 37 was 44m in length from 60m. The kimberlite unit contained limestone fragments and is very weathered.

The Company is planning further core and RC drilling to test for the extent of the kimberlitic body. The company will consult with some of the top diamond exploration experts to assist with the evaluation and assessment of this new discovery.

Vice President of Exploration for Brixton, Sorin Posescu stated, “This is definitely an interesting time for Brixton and for the Langis project. We are excited to have discovered diamond bearing kimberlitic rocks and look forward to doing additional work to understand the full extent and the economic potential of this discovery. The Langis project is very well located with excellent infrastructure, year-round road and rail access, power, and low-cost drilling, which ultimately translates to a low cost of exploration.”

Quality Assurance & Quality Control

Sealed samples were shipped by the Company geologists to SRC Geoanalytical Laboratories Diamond Services (GLDS) in Saskatoon for processing and caustic fusion analysis. SRC Geoanalytical Laboratories Diamond Services are ISO/IEC 17025:2005 Accredited Laboratory for laboratory procedures. The GLDS are a SCC Accredited Laboratory (Standard Council of Canada). The kimberlite samples were analyzed for micro diamond recovery by Caustic Fusion at >106 microns.

About the Langis and Hudson Bay Silver-Cobalt Project

Brixton’s wholly owned Langis and Hudson Bay past producing mines are located 500km north from Toronto, Ontario, Canada. The cobalt-silver mineralization occurs as steeply-moderately and in some cases shallow dipping veins and as disseminations within any of the three main rock types: Archean volcanics, Coleman Member sediments and Nipissing diabase. The Langis mine produced 10.4Moz of silver at 25 oz/t Ag and 358,340 pounds of cobalt and the Hudson Bay mine produced 6.4Moz of silver at 123 oz/t Ag and 185,570 pounds of cobalt. Historically, the Cobalt Camp produced 50M pounds of cobalt as a by-product of 500M ounces of silver production.

Mr. Sorin Posescu, P.Geo., VP Exploration, is a Qualified Person as defined under National Instrument 43-101 standards and has reviewed and approved this news release.

Source: Company Press Release