As a realistic alternative to magnetic bottle designs, commercial laser-based fusion is closer to reality than ever before using high-powered pulsed laser technology, writes Todd Ditmire, Co-Founder and CTO of Focused Energy

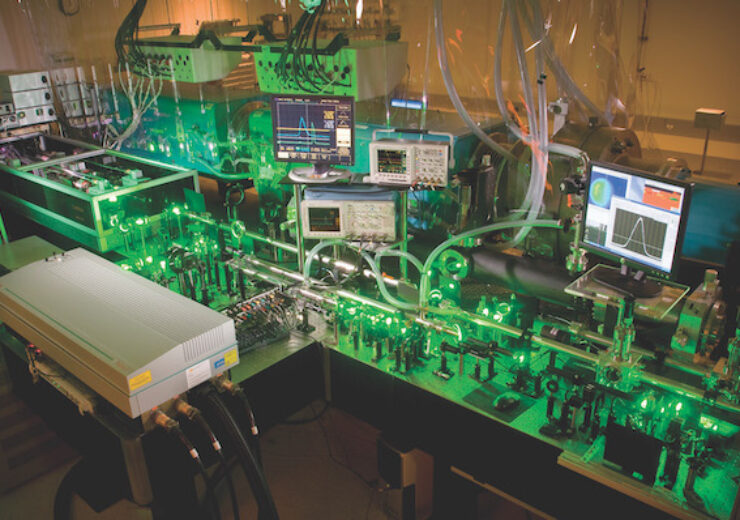

A petawatt laser is used to ignite the fusion reaction in this experimental set up (Credit: Focused Energy)

For more than half a century, scientists have been trying to recreate controlled solar energy on Earth. Theoretically, understanding the fusion of two hydrogen atoms to form a helium atom has long since ceased to pose any difficulties. However, the extreme conditions under which natural nuclear fusion takes place in the interior of our central star have so far prevented its practical application for electrical energy production. At about 15 million degrees Celsius, high thermal energy causes hydrogen atoms to collide so strongly that they fuse to form helium.

Can such fusion also be initiated under terrestrial conditions and used to generate energy? Yes – but only if it is possible to break through the electrical repulsion of two positively charged hydrogen nuclei using a technically controllable process. However, only at a very high temperature do the nuclei have enough energy to overcome this repulsion. At this temperature, the electrons of the atom are stripped, and the matter enters the fourth state – a so-called plasma.

Magnet versus laser

Different methods can be considered for creating appropriate fusion conditions in pressure and temperature. For many years, strong magnetic fields have been explored to hold such a hot fusion plasma, but now, pulsed laser light is considered a promising ignition mechanism for controlled nuclear fusion. It’s based on experimentally measured, and therefore, scientifically confirmed conditions.

In addition, research successes in recent years have brought groundbreaking progress to the development of strong magnets and high-power lasers. In this environment, a veritable ecosystem of companies from adjacent technology fields is currently emerging. These companies are collaborating with various materials, research companies, and diode manufacturers to advance their roadmap for commercially viable fusion reactors. It is perhaps possible to see the first fully operational demonstration plant by the 2030s.

Two-phase laser fusion

The two isotopes deuterium and tritium, whose atomic nuclei have one and two neutrons respectively in addition to a proton, serve as fuel for laboratory hydrogen fusion.

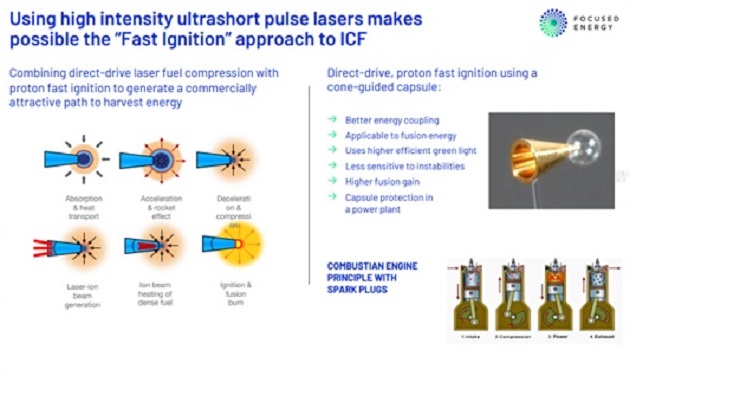

In a typical laser-driven fusion experiment, the two isotopes are housed in a pellet or target about two millimetres in diameter with a special coating. Then, in a specially constructed fusion chamber, laser light pulses strike the pellet and abruptly heat its shell. The shell vaporizes explosively and causes a recoil that extremely accelerates the hydrogen isotopes in the pellet, compressing and heating the fuel. The heating during compression is similar physics to how the cylinder in a diesel engine works (see the illustration below). In this heated and compressed fusion fuel, the isotopes collide and fuse, releasing so-called inertial fusion energy (IFE) forming two-proton helium.

How can electricity be generated from this process? Every fusion reaction leaves behind not only a helium nucleus, but also a free neutron that crashes against the reactor wall at high speed. There, the braking energy generates heat, which can be converted directly into electricity.

A slight variation of the laser-driven fusion approach works a bit more like a traditional combustion engine. A two-phase laser bombardment, or “fast ignition” for short, is the favoured approach for economic viability. First, a green laser flash compresses the capsule before a subsequent laser-generated proton beam heats the dense matter to ignition temperature. Similar to a gasoline engine, it works much more efficiently thanks to separate compression and ignition phases (see the illustration below). This approach is favoured for commercial energy production because it relaxes the stringent requirements of the lasers needed to compress the fuel, and it offers a more viable approach to the high energy gains of greater than 100 needed for electricity production.

The Focused Energy approach

The Focused Energy approach, shown in the figure above, builds on the tremendous progress made by the laser fusion research community over the past decade and introduces a few changes to increase the possibility for viable energy production. In addition to shifting from the diesel engine compression-heating approach to fast ignition, Focused Energy will also use slightly different laser parameters and target configuration. To perform fast ignition, Focused Energy will not use perfectly spherical targets as previous experiments have employed, but will instead use capsules with a cone inserted from the side. In addition to providing the second target for ultrashort pulse lasers to produce the proton “spark plug,” this configuration allows for easier filling of the pellet with fusion fuel and makes a more robust target for injecting into the reactor. In addition, Focused Energy will compress the fusion fuel with green light instead of the more traditional blue laser light used in previous experiments.

The benefit of using green laser light for pellet compression has to do, among other things, with an extended service life of the laser optics in this frequency range. In addition, the laser flashes can use the electricity from the socket more efficiently than in previous systems. These factors point to both the operational and process advantages of the two-phase fast ignition solution.

Focused Energy is taking this fast-ignition approach to IFE through high-intensity lasers, using the research and experiments conducted over the past 30 years. The company’s solution is inherently safe, efficient, and economically feasible – particularly in comparison to nuclear fission – and the energy produced will be a “CO2 friendly” alternative to support renewables.

Industrial process technology in view from the outset

In terms of the next steps for demonstrating high energy gain fusion ignition, it will be crucial to refine the production of the fusion target pellets and capsule robotic placement within the fusion chamber. There, the high-precision placement of new pellets must be able to occur every 3 minutes. By comparison, existing laser fusion facilities flash on average only every two hours.

The current conversion of laser energy to fusion energy is about 0.7, which was demonstrated by Lawrence Livermore National Laboratory’s National Ignition Facility (NIF) in August 2021. The experiment proved it’s possible to “ignite” a laser fusion pellet.

The goal is an energy yield efficiency of around 150. This is the factor by which the fusion energy obtained should exceed the laser energy irradiating the target. The target robot required for the demonstration system has been fully developed and is already in experimental use.

Another wrinkle to iron out concerns the optimization of pellet coating. Here, the aim is to achieve the lowest possible cost of materials and simplified production processes, while at the same time improving evaporation properties in the second ignition phase of fusion. In commercial operation, a pellet must not be more expensive than 50 cents. In addition, sufficient production capacity is needed. After all, with 24-hour reactor operation, the 10-hertz tempo in the fusion chamber requires no less than 860,000 pellets per day.

The future of energy is fusion

While there are still steps to be taken, inertial fusion energy through high-power lasers is now far closer than ever before to being viable under terrestrial conditions. The advances being made a point to market viability much sooner than expected – within the next ten years. Among others, these exciting recent advances include:

In August 2021, the NIF in California produced >1.3 MJ of fusion yield with 1.9 MJ of laser drive – a 70% conversion of laser energy to fusion energy.

Very high efficiency in laser-driven proton sources has been experimentally observed. More than 10% of picosecond laser pulse energy has been converted to a proton burst, and new techniques for fabricating cone-in-shell proton fast ignition targets are being developed.

Lasers with many hundreds of joules of energy operating at 10 Hz can now be constructed, and 100 J pulsed lasers operating at 10 Hz have been fielded. This is only within about a factor of 10 or 20 of what will be needed for the laser beams in an operating fusion power plant.

Commercialising fusion will have significant implications for the energy sector, provide a reliable way forward to solving climate challenges, and be a remarkable achievement in science and technology.

This article first appeared in Nuclear Engineering International magazine.