The Zhaoqing Dinghu combined heat and power (CHP) project is a 920MW gas-fired combined-cycle power plant under construction in the Guangdong province of China. It will provide clean electricity and support the heating demand of the industries in the Guangdong-Hong Kong-Macao Greater Bay Area (GBA) by replacing a number of small-size boilers in the region.

Guangdong Energy Group (formerly Yudean Group) is developing the project with an estimated investment of £747m ($1bn). The Guangdong government owns 76% interest in the company.

Construction works started after the Guangdong Provincial Development and Reform Commission found that the project complies with the guidelines of China’s National Development and Reform Commission (NDRC) in June 2020.

Scheduled for commissioning in 2023, the Zhaoqing Dinghu cogeneration plant will generate up to 3.5 billion kilowatt-hours (kWh) of electricity and about 6.27 million gigajoules (GJ) of heat a year.

Zhaoqing Dinghu CHP project location

The combined heat and power plant is being developed in the Dinghu district of Zhaoqing city, Guangdong, China.

The project site occupies 150,689m² on the eastern side of Zhaoqing Dinghu industrial park located in the Beishui village of Yong’an town.

Zhaoqing Dinghu CHP plant make-up

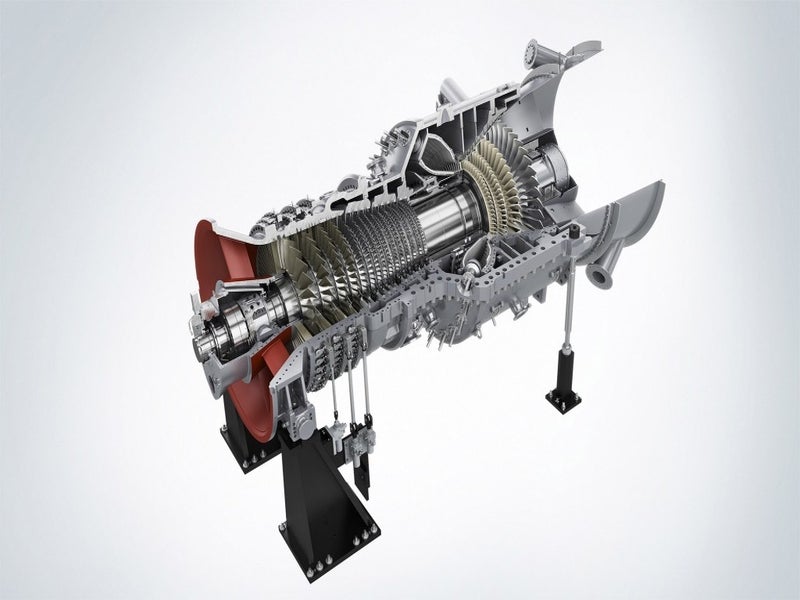

The Zhaoqing Dinghu CHP plant will comprise two 460MW combined-cycle units, each equipped with one SGT5-4000F gas turbine, one steam turbine, two generators and one SPPA-T3000 control system from Siemens. Each unit will also use a waste heat recovery boiler supplied by Dongfang Lingri Boiler.

Zhaoqing Dinghu will be the first project in the world to adopt Siemens latest F-class combined-cycle design that can operate at more than 60% efficiency and cut carbon dioxide (CO2) emissions by 60%.

The facility is estimated to consume 718.65 million m³ of natural gas a year. Its flue gas will be discharged through an 80m-tall chimney, while the exhaust gas from the waste heat recovery boiler will be released through a 15m-high stack.

Other components of the plant will include a natural gas pressure regulating station, closed-loop cooling water system, make-up and recirculation pumps and screw air compressors.

The main electrical equipment will comprise a 220kV gas-insulated substation (GIS), low and medium-voltage switchgear, 220kV busbar and protection relays, and the main and auxiliary transformers.

Contractors involved

Siemens Energy signed an agreement with Guangdong Energy Group to supply the main equipment including F-class gas turbines, steam turbines, generators and control systems for the Zhaoqing Dinghu CHP project in February 2021.

Dongfang Lingri Boiler was selected to supply waste heat recovery boilers, while Zhonghuan Guangyuan Environmental Engineering Technology was engaged to carry out the environmental impact assessment (EIA) for the project.

Guangdong Tianxin Power Engineering Inspection was contracted to monitor and inspect the soft ground foundation treatment works at the project site.

Guangdong Mingyang Electric Company was selected to supply 6kV switchgear for the project in November 2021.