The Whabouchi lithium project located in James Bay region of Quebec province, Canada, is expected to be one of the richest lithium spodumene deposits in the world, both in terms of volume and grade.

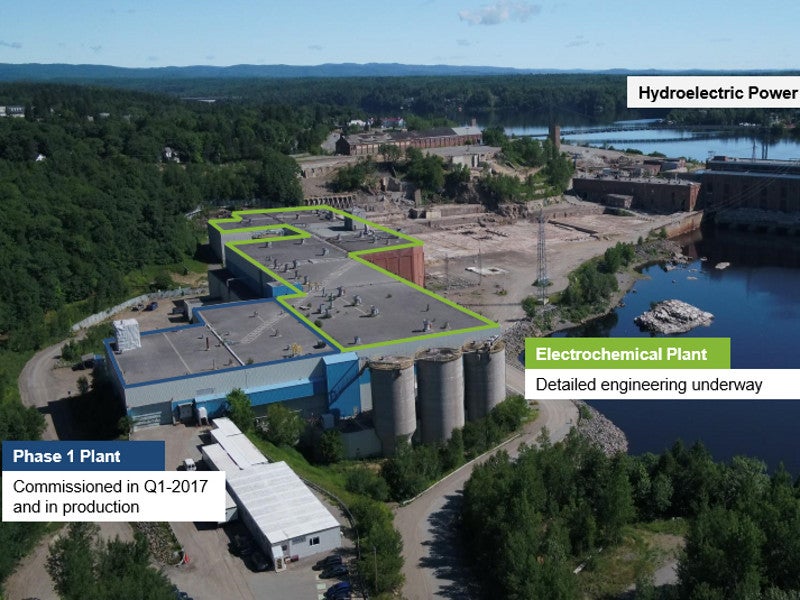

The project is being developed by Nemaska Lithium as an open-pit and underground operation, with an expected mine life of 33 years. The development will include a mine and an electrochemical plant to process the recovered ore and convert spodumene concentrate into lithium hydroxide.

Feasibility study of the project was updated in 2018, while commercial operations are expected to be started by the second half of 2019. The capital cost of the project is estimated at C$801m ($616m).

Whabouchi lithium project location, geology, and mineralization

The Whabouchi lithium mine lies approximately 30km from the Nemaska community and 300km from the town of Chibougamau. It is located in the north-eastern segment of Superior Province, within the Canadian Shield craton.

The property is made up of a block containing 33 claims, extending in 1,761.9ha, and a mining lease. The area is topographically flat except for the local ridge with competent pegmatites that form the surface expression of the mineral deposit.

Lithium mineralization is mostly identified in medium to large spodumene crystals of up to 30cm in size.

Whabouchi lithium project reserves

The proven and probable reserves of Whabouchi open-pit mine are estimated at 24Mt, while the underground mine is estimated to contain 12.7Mt grading 1.16% Li2O.

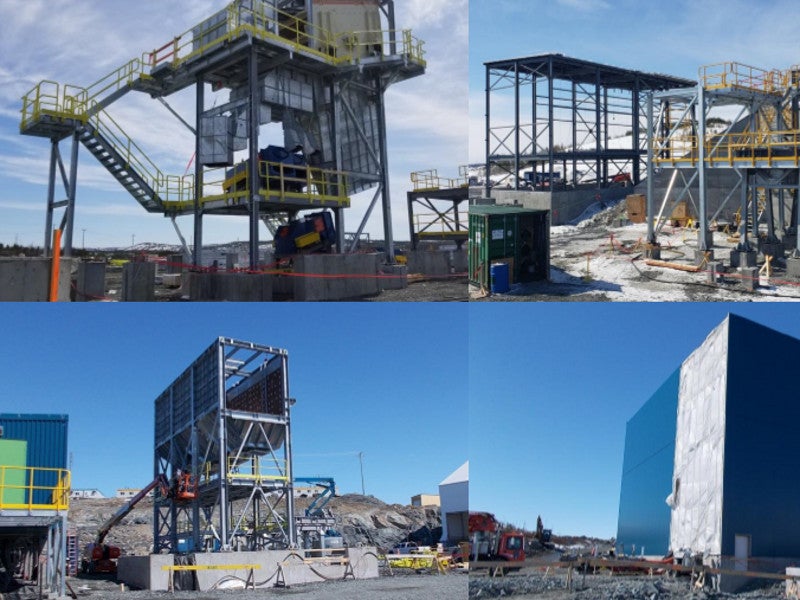

Mining of ore at Whabouchi lithium project

The Whabouchi open-pit mine is proposed to be mined using conventional method, involving truck and shovel followed by drill and blast operation. It will be developed to a maximum depth of 244m, during its operational period of 24 years.

Underground mining is expected to be conducted during the last ten years of the mine life, using longhole stoping mining method.

The underground mine will be located underneath the final open-pit floor mined during the 24th year of the operation.

Ore processing at Whabouchi

The ore mined will undergo three stages of crushing namely primary, secondary, and tertiary following which, the fine ore is screened.

The screened product will be forwarded to grinding circuit, dense media separation (DMS), and a wet magnetic separation (WMS) circuit to remove minerals bearing iron oxides.

The oversize product will be upgraded in the DMS circuit, followed by mica hydro-separation to produce a coarse spodumene concentrate, a tailings product, and a middlings product.

The coarse concentrate will be dried in a rotary dryer prior to treatment by a dry magnetic separation system. Magnetic product will be removed from the concentrate, while the non-magnetic product will be the initial portion of the final spodumene concentrate.

The DMS middlings product will pass through grinding, mica hydro-separation, and flotation processes to produce spodumene flotation concentrate.

The resultant flotation concentrate will be thickened, filtered, and combined with the dry DMS concentrate before being trucked to Chibougamau. It will be loaded onto railcars and forwarded to the Shawinigan electrochemical plant for further processing.

The Shawinigan plant will employ a unique membrane electrolysis process to produce 33,000tpa of lithium carbonate-equivalent (LCE) in the form of lithium hydroxide monohydrate crystals and lithium carbonate powder.

Infrastructure

Access to the Whabouchi property is through Route du Nord, the main all-season gravel road linking Chibougamau and Nemaska.

Power supply for the project will be provided from the Hydro-Québec Nemiscau sub-station, through a new 12km-long, 69kV overhead power line.

Workers will be accommodated in two accommodation camps, to be constructed near Relais Routier Nemiscau. A 169-room camp facility is already installed for the project.

Underground wells will be the main source of fresh and fire water for the project. A pumping station equipped with two electric pumps will pump water to the surface, which will be stored in the fresh / fire water tank located south of the concentrator.

Contractors involved

ASEA Brown Boveri (ABB) was engaged as the key technical supplier and project management consultant with regards to the electrification and automation of the project.

Met-Chem, a division of DRA Americas, was engaged to prepare the feasibility study of the Whabouchi lithium mine.