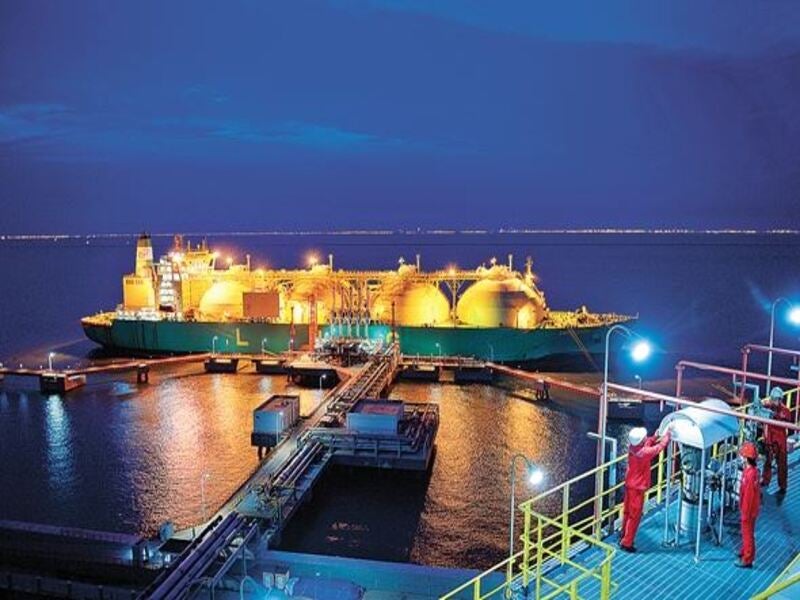

The Tianjin LNG receiving terminal at the Port of Tianjin, China is undergoing the second phase expansion to increase its LNG import and regasification capacity from six million tonnes per annum (Mtpa) to 10.8Mtpa.

Owned and operated by Sinopec Group, the Tianjin LNG) receiving and regasification facility is China’s first indigenously-developed LNG terminal featuring domestically-made process technology.

The National Development and Reform Commission (NDRC) of China approved the construction of the Tianjin LNG import project in July 2014. The terminal was brought online with an annual LNG receiving capacity of 3Mt and a gas supply capacity of four billion cubic metres (bcm) per year in March 2018. The first phase expansion doubled the terminal’s receiving capacity to 6Mt and the gas supply capacity to 8bcm.

The construction works for the second phase expansion were started in March 2019. Scheduled for commissioning by 2022, the phase two expansion will increase the annual gas transmission capacity of the terminal to 13.6bcm, which will serve the increased natural gas demand in the Beijing-Tianjin-Hebei region of northern China.

Location and site details

The Tianjin LNG receiving terminal is located on a 60ha-site in the Nangang Industrial Zone at the Tianjin port city of China.

The presence of industrial and free trade zones in Tianjin’s Binhai New Area benefits the project by reducing the construction costs associated with the storage and transportation facilities.

Tianjin LNG receiving terminal development

The phase one development of the Tianjin LNG receiving terminal added a total LNG storage capacity of 640,000m³ along with transshipment facilities.

The terminal consists of two berths for handling three 270,000m³-capacity LNG vessels each. It also has a berth for handling roll-on/roll-off (Ro/Ro) ships, and another berth for 3,000 deadweight general cargo vessel.

The terminal facility also includes cold storage, a refrigeration station, and an auxiliary station.

The phase two development will include the addition of five 220,000m³-capacity storage tanks, 12 gasification units, 12 high-pressure pumps, four export metering skids, three seawater pumps, a combustion vaporiser, and ancillary facilities. It will also include the construction of an additional berth for LNG vessels.

Gas supply from the Tianjin LNG receiving terminal

The regasified LNG from the Tianjin receiving terminal is supplied to the Beijing-Tianjin-Hebei-Shandong region in northern China through the Sinopec natural gas pipeline network.

The terminal is connected to the Shandong natural gas pipeline, the Ordos-Anping-Cangzhou gas pipeline, as well as the Wen 96 and Wen 23 gas storage facilities.

Contractors involved

China National Offshore Oil (CNOOC) Engineering was awarded the engineering, procurement and construction (EPC) contract by Sinopec for one cryogenic LNG storage tank for the Tianjin LNG terminal phase one.

Sinopec Fourth Construction Company was contracted for the second phase development.

Hyundai Heavy Industries delivered a floating storage regasification unit (FSRU) for the Tianjin LNG receiving terminal in April 2018, while Ampo Group supplied cryogenic valves for the project.

Tianjin LNG receiving terminal operations

The Tianjin LNG terminal received the first LNG cargo from Australia aboard the Zhongneng Beihai tanker with a carrying capacity of 160,000m3 in February 2018.

Höegh Esperanza was commissioned as a floating, storage and regasification unit (FSRU) at the Tianjin LNG receiving terminal in November 2018. The FSRU comprises an open and closed-loop regasification facility. The vessel has an import capacity of 6Mtpa of LNG per year and a storage capacity of 170,000 cubic meters.

The terminal received a total of 14.04Mt of LNG and supplied 15.33bcm of regasified LNG in 2018.