Segovia gold project is an underground mine located in the Antioquia Department of Colombia. Gran Colombia Gold is the owner and developer of the mine, which has been operational for more than 150 years. The mine has produced more than five million ounces of gold since its inception.

Gran Colombia updated a pre-feasibility study (PFS) to expand the Segovia underground operations in April 2019. The project is estimated to require a sustaining capital investment of £105.2m ($131.8m).

The mine produced 200,964 ounces (oz) of gold for the year ended March 2019. It is expected to be operational until 2023, at current production rate.

Segovia gold project location, geology, and mineralisation

The Segovia gold project is located in the Segovia-Remedios mining district, approximately 180km to the south-west of Medellin, the capital city of Antioquia.

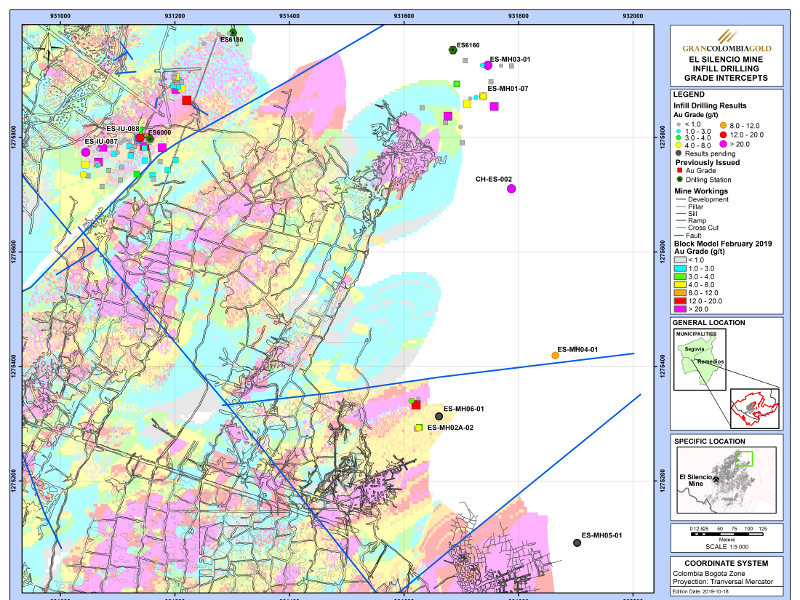

The deposit is divided into five vein systems namely Providencia, El Silencio, Sandra K, Carla, and Las Verticales.

The Segocia-Remedios district is situated with the Colombian Central Cordillera, which comprises metamorphic and igneous rocks angled north-south. Unconsolidated alluvial material is found in the region, while a thick layer of saprolite around 60m deep is formed due to the local climate.

The gold mineralisation is associated with mesothermal quartz-sulfidic veins and diorite to granodiorite rocks of Segovia Batholith. The main sulphides identified at the deposit include pyrite, chalcopyrite, galena, and sphalerite.

Segovia gold project reserves

The proven and probable ore reserves at Segovia gold project are 1.9 million tonnes (Mt) of ore graded at 11.02g/t of Au. Contained gold is estimated to be 687,926oz.

Mining and ore processing at Segovia gold project

The mining methods currently employed at Segovia are room-and-pillar mining as well as cut-and-fill.

The room-and-pillar mining method is divided into two phases, with the first phase employing a traditional room and pillar layout. The second phase extracts additional material from pillars in addition to the stated extraction ratio.

Gran Colombia also uses two methods of cut-and-fill. In primary cut-and-fill method, diesel load, haul and dump machines (LHDs) and electric/hydraulic jumbo drills are used to extract the ore. The vein is accessed through cross-cuts and drifting along the vein.

Whereas, jackleg drills are used to drill and blast the mineralised veins and ore recovery is performed either manually or with a slusher, in the secondary cut-and-fill method.

The ore is currently processed at the Maria Dama processing plant, the capacity of which will be increased to 1,500 tons per day.

The run-of-mine (ROM) material will be fed to a conventional crush and grind circuit followed by gravity concentration, flotation, and cyanidation of the flotation concentrate. The resultant product undergoes Merrill-Crowe precipitation, while the resultant zinc precipitate and gravity concentrate will be refined to produce the final dore product.

Infrastructure

The Segovia/ Remedios area is accessible through a paved four-hour highway from Medellin.

The Segovia gold project receives electricity from two sources – the national grid and the Dona Teresa hydroelectric project, which is operated by Proveniente de Central Dona Teresa (PCH). The power is supplied to the site through 44kV lines.

Water required for processing, approximately 100m³/hr, is pumped from the La Tupia pond as well as through underground dewatering activities.

Contractors involved

The PFS report for the Segovia project was prepared by SRK Consulting.

Geomecanica del Peru Consulting collected the geotechnical information of the project in 2017.