The Sabiya West gas-fired combined-cycle power plant is the biggest power station in Kuwait. Owned and operated by Kuwait’s Ministry of Electricity and Water (MEW), the 2GW gas-fired power station comprises three combined-cycle power blocks.

The Sabiya West power station has been undergoing an upgrade to increase its total output by more than 7% as part of the New Kuwait Vision 2035 to improve the performance of the country’s power and water infrastructure. The first power block of the facility was upgraded by 2019.

The construction on the £1.59bn ($2.65bn) Sabiya West combined-cycle power project was started in September 2009; while the plant commenced simple-cycle operation with approximately 1,400MW installed capacity in phase one in June 2011.

The plant was converted into combined-cycle operations with a total generating capacity of 2GW in phase two that was completed in July 2012.

The Sabiya West combined-cycle power station accounts for approximately 23% of Kuwait’s total electricity demand. The other major gas-fired power station in the country is the 1.5GW Az-Zour North One combined-cycle power plant located approximately 100km south of Kuwait city that was commissioned in December 2016.

Location

The Sabiya West combined-cycle power plant is located at Subiyah, Al Jahrah, approximately 32km away from Kuwait City, Kuwait.

Sabiya West power plant make-up

The 2GW power station consists of three gas-fired combined-cycle units. Each power block is equipped with two GE 9FA gas turbines and one GE D11 steam turbine from General Electric, and two 569ºC class 270t/h heat recovery steam generators (HRSG) from Hyundai Heavy Industries.

The GE 9FA series gas turbines are single shaft heavy duty combustion turbines designed to operate at 50HZ frequency in large-scale combined-cycle configuration. The gas turbine provides up to 56% combined-cycle efficiency with fast start-up and high ramp rates. It comes with an 18-stage compressor with variable inlet guide vanes and a three-stage hot gas path (HGP) for advanced cooling.

The 3,000rpm GE D11 steam turbine consists of a high pressure (HP), an intermediate pressure (IP) and a double flow low pressure (LP) section. The turbine is designed to operate at 124 bar steam pressure and 566ºC steam temperature. The rated output of the steam turbine is 295MW.

Feed gas supply

The Sabiya West combined-cycle power plant uses natural gas as the primary fuel while distillate is used as the backup fuel.

The Kuwait Oil Company (KOC) supplies feed gas for the power station from a pipeline originating from the Mina al-Ahmadi refinery facility.

Sabiya West combined-cycle power plant upgrade

The combined-cycle gas turbine facility was migrated to the Asset Performance Management (APM) software solution in 2017. The main equipment of the facility, including the combustion turbines, hydrogen-cooled generators, heat recovery steam generators, steam turbines, and condensers were digitised.

The on-going upgrade programme at the power station includes the installation of GE’s Advanced Gas Path (AGP) turbine upgrade solution to boost the output of the gas turbines by more than 6%.

The upgrade to two gas turbines of the first power block has already increased the power production capacity of the unit by more than 35MW.

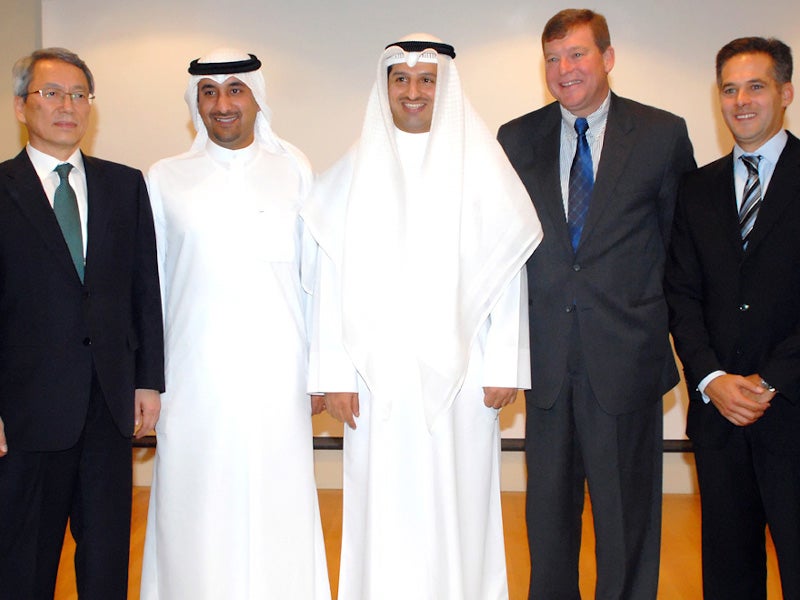

Contractors involved

GE in consortium with Hyundai Heavy Industries (HHI) was awarded an engineering, procurement, and construction (EPC) contract worth £1.59bn ($2.65bn) for the 2GW Sabiya West power project September 2009.

GE’s share of the contract amounted to approximately £800m ($1.3bn). It supplied six gas turbines, three steam turbines, nine generators as well as the plant level control protection system, while HHI supplied six HRSGs for the plant.

Alghanim International was awarded a subcontract worth £274.56mn ($450mn) by HHI for the main civil and electro-mechanical construction works for the project, while the Heavy Engineering Industries & Shipbuilding Company (HEISCO) was subcontracted for the construction and installation of gas storage tanks, main extraction control valves as well for the piping works at the power station.