The Patterson Lake South uranium project is located in Northern Saskatchewan, Canada. Fission Uranium fully owns and is developing the project, which hosts the Triple R uranium deposit.

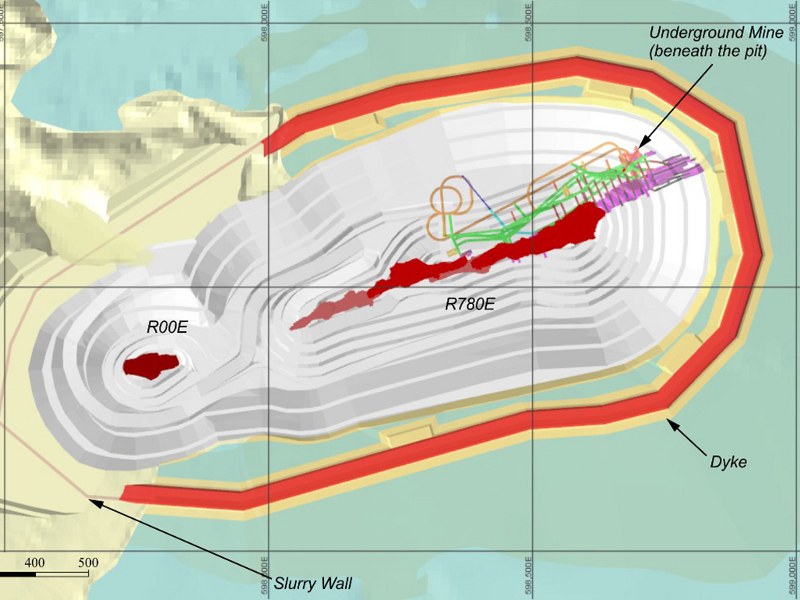

Fission Uranium conducted two pre-feasibility studies (PFS) for the project, including one that proposed combination of open-pit and underground mining methods and the other that proposed underground only.

The PFS for the hybrid model was completed in April 2019, while that for the underground only was completed in September 2019.

The hybrid mine development approach is estimated to cost £800m (C$1.33bn), while the underground only approach will cost approximately £830m (C$1.45bn). The ore processing rate over the mine life of approximately seven years is expected to be 1,000 tonnes per day (tpd).

Project Gallery

-

Fission Uranium is developing the Patterson Lake South property located in Saskatchewan, Canada. Image courtesy of FlickrLickr.

-

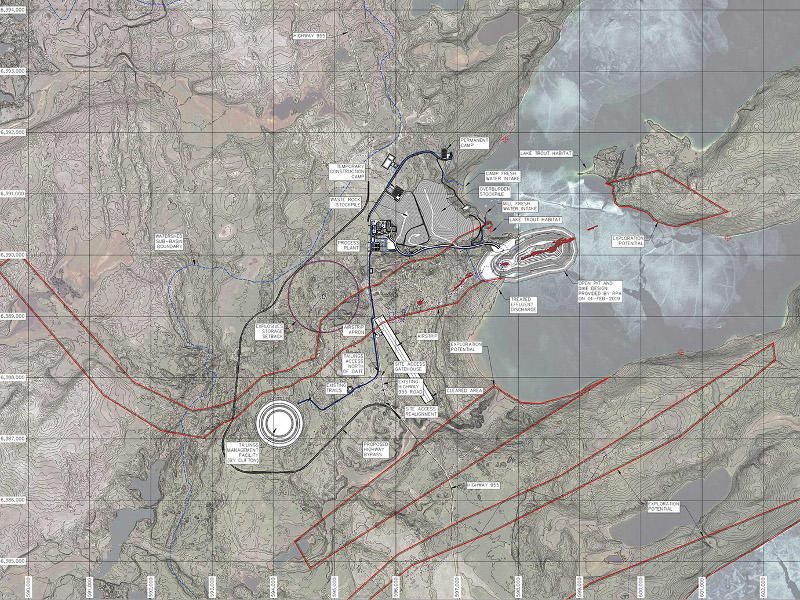

Construction works at the uranium project are expected to last for three years. Image courtesy of Fission Uranium.

-

The underground mining will be conducted for two years at a rate of 1,000tpd. Image courtesy of Fission Uranium.

The construction of the uranium project is expected to take three years for completion. The production during the first five years is expected to be 78.7 million pounds (Mlbs) of triuranium octoxide (U3O8).

Patterson Lake South project location, geology, and mineralisation

The Patterson Lake South uranium project is located within Athabasca Basin in the province of Saskatchewan, Canada. It comprises 17 contiguous mineral claims extending in 31,039ha, approximately 550km from the city of Prince Albert.

The Triple R deposit is a large, basement hosted, structurally controlled, sub-vertical, near-surface uranium deposit. Two geological domains lie underneath the property namely - Clearwater Domain in the west and the Lloyd Domain in the east.

Most of the mineralisation is hosted within metamorphosed basement lithologies and the Devonian age sandstones.

Reserves at Patterson Lake South property

The project is estimated to contain reserves of 2.9 million tons (Mt) of ore, grading 1.42% U3O8, as of April 2019 estimates. Contained U3O8 is estimated to be 90.5 million pounds (Mlbs).

As of September 2019 estimates, the underground reserves at PLS are estimated to be 2.3Mt, graded at 1.61% U3O8. The contained metal is estimated to be 81.4 million pounds (Mlbs) of U3O8.

Underground mining and ore processing at Patterson Lake South uranium project

Final decision on the mining method at the Patterson Lake South project is yet to be taken.

Longhole stoping mining method, along with isolated pockets of cut-and-fill method, will be used if the underground-only option is chosen. The deposit will be accessed through a decline developed on the western side of the deposit, which was excavated by using New Austrian Tunnelling Method (NATM).

Two vertical shafts, one fresh air intake shaft, and one exhaust air shaft, will be excavated sequentially in addition to the decline.

Fission Uranium proposes to use artificial ground freezing to extract the mineralised material near the contact between overburden and bedrock. Brine solution is proposed to be pumped by a refrigeration plant through holes to create a frozen cap, following freezing activity.

The processing plant at the Patterson Lake South property is proposed to be based on conventional processing technology.

Conventional processing technology, involving grinding, solvent extraction, and leaching processes, will be used to treat the PLS ore. Liquids and solids from the leached material will be separated by using counter current decantation, which will be followed by yellowcake precipitation. The resultant product will be packaged for delivery to customers.

Ancillary facilities at the processing plant will include an on-site acid generating facility.

Infrastructure

The project can be accessed through Highway 955, which passes through the property. Power supply for the project is proposed to be provided by an onsite power plant, which will feature six 2MW generators, with an option to add one more unit.

Water required for the mining operations will be sourced from Patterson Lake and pumped to a storage tank in the effluent treatment plant.

Contractors involved

Roscoe Postle Associates (RPA) prepared the pre-feasibility study for underground mining of the Patterson Lake South Property.

RPA was supported by BGC Engineering, Wood Canada, Newmans Geotechnique, Melis Engineering, Clifton Associates, Artisan Consulting Services, and Thyssen Mining Construction of Canada.