Mt Carrington gold and silver project is being developed in northern New South Wales, Australia, by White Rock Minerals (WRM) in two phases.

Pre-feasibility study (PFS) of stage one of the Mt Carrington mine was completed in December 2017. WRM aims to commence construction of the project in the first quarter of 2020 and produce first gold by the fourth quarter of 2020.

The first stage of the project is expected to produce 148,000oz of gold over its initial mine life of four and half years. The second stage is expected to be focused on silver-only indicated mineral resources.

Mt Carrington project location, geology, and mineralization

The Mt Carrington project is located near the town of Drake on the Bruxner Highway. The tenement extends in more than 22 mining leases and a 183km² exploration license.

Project Gallery

-

The high-grade Mt Carrington project is estimated to produce 148,000oz of gold in its first stage. Image courtesy of White Rock Minerals.

-

White Rock Minerals is developing the gold and silver project in New South Wales, Australia. Image courtesy of White Rock Minerals.

-

Ore will be processed at a 1Mtpa plant, which includes a conventional carbon-in-leach (CIL) circuit. Image courtesy of White Rock Minerals.

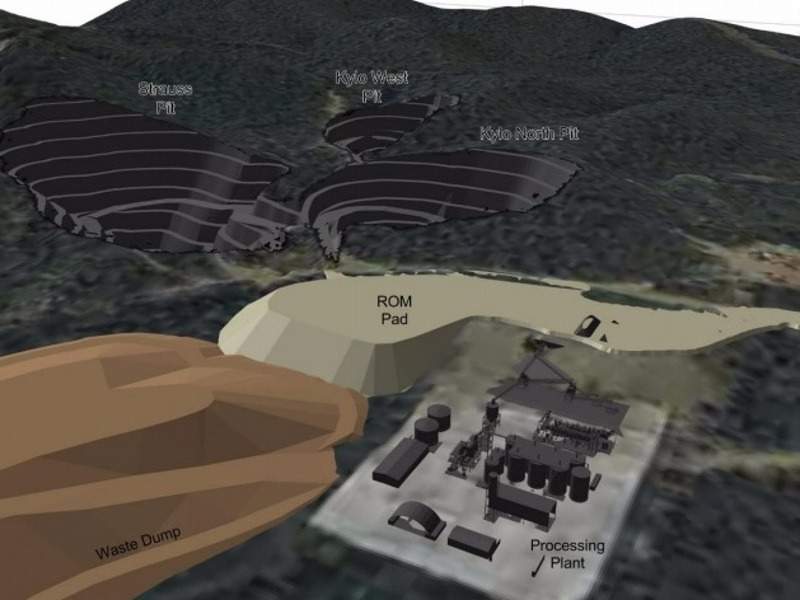

The Australian gold-silver project comprises two major gold deposits and hosts epithermal mineralization, which is associated with a large 250km² collapsed volcanic caldera structure. The deposits are further classified into three gold pits namely Kylo North, Kylo West, and Strauss.

The gold-only deposits consist of a primary zone of quartz-jasperoid and quartz-based metal veins overlain by an oxide cap and a thin transition zone. Low sulphidation epithermal vein type mineralization is found in the deposits. In addition to gold, the project hosts a minor amount of silver and significant quantities of zinc, copper, and lead.

Mineralization occurs from surface, is open along strike, and dips downwards. It is mostly associated with sulphides, pyrite as well as certain base metal sulphides, notably sphalerite and chalcopyrite.

Reserves

The Mt Carrington project is expected to host probable ore reserves of 3.47 million tonnes (Mt) grading 1.4g/t gold and containing 159,000oz of gold.

Indicated and inferred mineral resources are estimated to be 341,000oz gold and 23.2Moz of silver.

Mining and ore processing at Mt Carrington

Conventional open-pit method of mining including drill and blast followed by load and haul using trucks and excavators will be applied at the project.

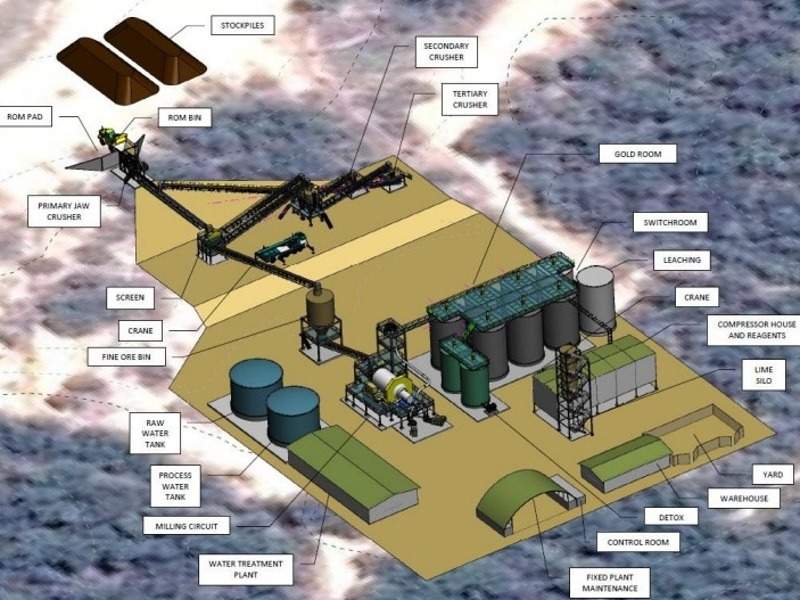

Ore will be processed at a 1Mtpa plant, where the oxide, transitional, and primary sulphide material will be treated in a conventional carbon-in-leach (CIL) circuit.

Run-of-mine ore will undergo three stages of crushing in primary, secondary, and tertiary cone crushers to produce a P80 product size of 10mm. The crushed fine ore will be stored in a 200t bin before being ground in a 3.5MW single-stage ball mill. The product size will be further reduced to 75µm in a classification circuit.

The resultant product will be leached with cyanide and adsorbed onto activated carbon using one pre-aeration tank, followed by a six-stage CIL circuit. It will further undergo acid washing and elution in separate columns.

Barren carbon will undergo thermal regeneration before being forwarded to the CIL circuit and then undergoes electro-winning onto steel wool cathodes. The calcined steel wool cathodes will be smelted to produce a final gold doré product.

Financing

WRM signed a binding conditional term sheet with Cartesian Royalty Holdings (CRH) in June 2016 and secured financing for developing the Mt Carrington project.

The financing comprises a two-tranche equity investment of A$1m ($746,000) and a future streaming financing of $19m in return for a share of gold and silver production.

The equity investment will be used for preparing the definite feasibility study and environmental impact statement. It will also be used for meeting the working capital requirements, while streaming financing will be used for the construction and commissioning of the project.

Infrastructure

Access to the project site will be provided primarily by the existing site entrance off the Cheviot Hills Road.

Existing infrastructure includes a connection to the NSW state power grid, haul roads, previous processing plant foundation, and a water treatment plant. It also comprises a 1.5Mt tailings storage facility in addition to a 750 million litre freshwater dam.

Raw and process water will be collected either from the existing Humphries Creek dam on the property or discharge water from the TSF through overland pipelines and transfer pumps. Process water will also be collected in containment ponds, which are intended to collect pit and surface run-off water.

Power for the project will be sourced from the local grid supply at 11kV and distributed via a high-voltage switchyard.

Temporary construction and permanent operations staff will be accommodated at the local township of Drake and surrounding towns of Casino and Tenterfield.

Contractors involved

Mining Plus and Mincore, supported by Mannerim Partners, prepared the PFS of the project.

WRM engaged RW Corkery to assist in managing the environmental permitting process, while Umwelt is responsible for preparing a social impact assessment (SIA) and community engagement strategy for the project.