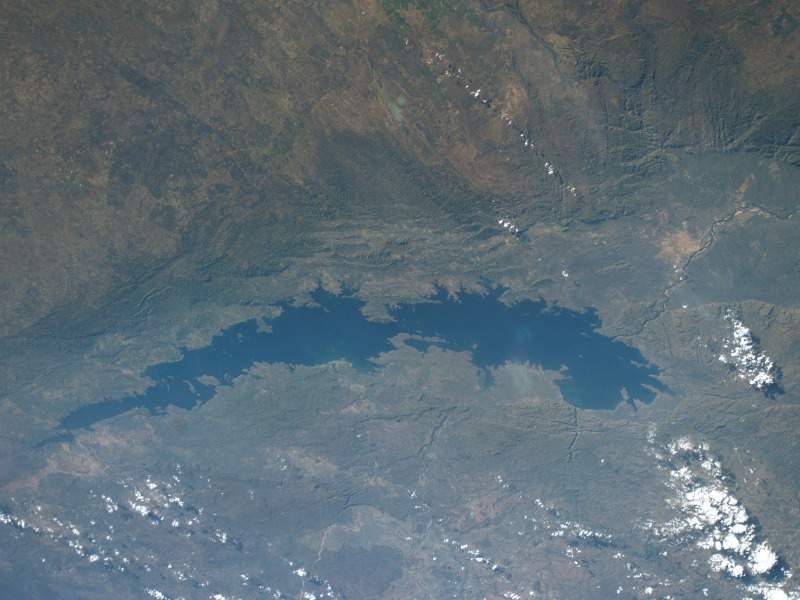

Situated 200km south of Lusaka, Zambia, Matunga uranium project consists of three contiguous mining licenses covering 720km² immediately north of Lake Kariba near Siavonga, in the southern province of Zambia.

The uranium project is being undertaken by GoviEx Uranium, a Canada-based mineral resource company focused on African uranium properties, which is also developing the Madaouela uranium project in Niger.

The preliminary economic assessment (PEA) of the Mutanga project was completed in November 2017. It predicts annual production of 2.4 million pounds (Mlb) of triuranium octoxide (U3O8) with 88% uranium recovery rate, over initial 11years of mine life.

A definitive feasibility study for the uranium project is expected to be undertaken in 2019, while production is expected to start by 2023.

Matunga uranium project development details

GoviEx acquired the Matunga project from Denison Mines in 2016. At the time of acquisition, the project consisted of three uranium deposits namely Mutanga, Dibwe, and Dibwe East.

Later in 2017, GoviEx acquired neighbouring Chirundu and Kiraba deposits from African Energy Resources and integrated them with the Matunga uranium project development plan.

The project currently consists of five main uranium deposits under three fully-permitted contiguous mining licenses totalling 140km in strike length. It also includes two more prospective licenses covering 100km².

The pre-production capital cost of the uranium project is estimated to be $121m, while the operating cost is estimated to be $31.1 per pound of U3O8.

Matunga is evaluated as a large-scale uranium project with low capital and operating costs.

GoviEx forecasts increased market demand for uranium by the time Matunga project is brought into production, because of the recent revival of nuclear power generation worldwide.

GoviEx received “Best Mining Project” Gold award at the 2017 Africa Investment Forum and Awards (AIFA) ceremony held in Paris, France, because of the quality of investment, and innovativeness in its two African uranium projects including Matunga.

Matunga geology and mineralisation

Matunga uranium deposits are located within the Karoo Supergroup, a thick sedimentary strata spread across most part of southern Africa, which was formed during late Carboniferous to late Triassic period.

Uranium mineralisation at Matunga is found disseminated in mudstones, siltstones, pyrites as well as in pore spaces, joints and other fractures hosted within the 400m-thick Escarpment Grit formation of the Karoo Supergroup in southern Zambia.

Uranium reserves at Matunga

Matunga uranium project was estimated to hold 21.6 million tonnes (Mt) of measured ore resources grading 317 parts per million (ppm) U3O8 containing 15.1 million pounds (Mlbs) of triuranium octoxide, as of November 2017.

Inferred resources were estimated to be 74.6Mt grading 273 ppm U3O8, containing 44.9Mlbs of triuranium octoxide.

Mining method for Matunga

Matunga will be a conventional, shallow, open-cast mining operation involving drilling, blasting, loading and hauling, as the economic uranium mineralisation is found within 125m of surface.

Uranium processing at Matunga

The run-of-mine ore will be trucked to three separate ore preparation and leach areas adjacent to the pits, where it will undergo two-stage crushing, agglomeration and acid heap leaching. The leach solution will be sent to the central processing facility for uranium oxide production.

The crushed material will be transported to the leach pads by conveyors and stacked in 4m lifts, which will be irrigated with acidic solution to dissolve the uranium. The leached solution will percolate the heap and drain into the intermediate pregnant leach solution (PLS) pond and pumped back to the heap till the solution has sufficient uranium content.

The uranium-rich lixiviant solution will then be directed by open ditches to the pregnant leach solution pond and pumped from there to the central processing facility, where uranium will be stripped and loaded into resin.

The barren leach solution will be sent back to the barren pond for reuse as leach solution. The central processing facility will produce dry uranium oxide (yellowcake), which will be loaded into 1,000kg sealed drums.

Further, the drums will be transported to the nearby storage facility from where they will be loaded into 6.3m sea containers for transport by truck to Walvis Bay port, for export.

Infrastructure facilities

The project site will be accessed through a 26km new sealed road connected to the Siavonga Highway at Lusitu.

Matunga mine will get electricity supply via a new 66kV transmission line connected to nearby Chirundu substation.

Process water for the project will be sourced either from bore wells or from the Kafue and Zambezi rivers located near the project site.

Other infrastructure will include waste rock dumps, ore stockpiles, mine workshops, mine camp, sewage treatment plant, raw water tank, administration building and an assay laboratory.

Contractors involved with Matunga uranium project

SRK Consulting prepared the technical report on the preliminary economic assessment of Matunga uranium project.

Orway Mineral Consultants provided modelling service for the leach test during the metallurgical test work programme for Matunga uranium project.