The Lone Star Express pipeline expansion project in Texas, US was put into service in August 2020, increasing the capacity of the existing NGL pipeline system to 907,000 barrels per day (bpd).

Owner and operator Energy Transfer undertook the expansion project as part of its 2020 capital programme.

The NGL pipeline expansion involved the construction of a 566km-long, 24in-diameter pipeline between Wink in Winkler County and the Morgan Junction in Bosque County, where it connects to the existing 30in Lone Star Express pipeline south of Fort Worth, Texas.

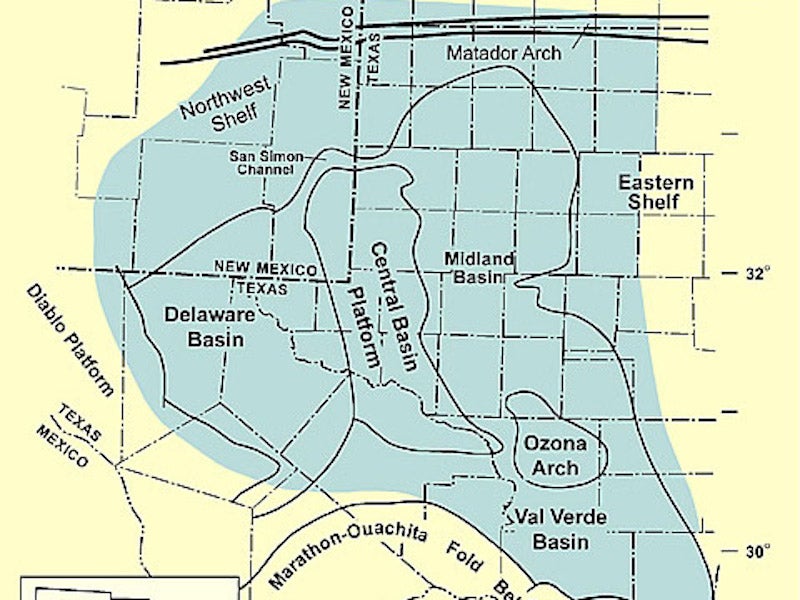

The expansion added approximately 400,000bpd of NGL capacity to the existing Lone Star Express Pipeline, which transports mixed NGL and other hydrocarbons from processing plants in the Permian and Delaware basins in West Texas to Energy Transfer’s integrated NGL storage and fractionation facility in Mont Belvieu.

Existing Lone Star Express NGL pipeline

The original Lone Star Express pipeline is an 861km-long, and 24in and 30in interstate pipeline capable of transporting up to 507,000 barrels of NGL a day to the Mont Belvieu NGL storage and fractionation facility.

Built with an estimated investment of approximately £1.4bn ($1.8bn), the pipeline came online in 2016.

Lone Star Express pipeline expansion details

The Lone Star Express pipeline expansion project to deliver additional capacity to the Mont Belvieu facility was announced in November 2018.

The pipeline was buried 4ft-deep or more beneath the ground surface with the regulating devices and safety valves installed along the route for the safe operation of the pipeline.

Mont Belvieu NGL storage and fractionation facility

The Mont Belvieu integrated NGL storage and fractionation facility is located in Chambers County, Texas, approximately 483km away from the Class 1 area of Caney Creek Wilderness. The facility is located in an ozone non-attainment area.

Strategically located along the US Gulf Coast, the Mont Belvieu facility has connectivity to more than 35 petrochemical plants, fractionators, refineries, the Houston Ship Channel trading hub, and third-party pipelines.

The Mont Belvieu facility was commissioned in 2012 and it currently consists of seven fractionation facilities, where NGLs delivered from various sources are separated to gas products including ethane, propane, butanes, and natural gasoline.

Energy Transfer plans to construct the eighth fractionator, which will increase the total fractionation capacity from 900,000bpd to more than one million bpd when commissioned in 2022.

The facility can store up to 50 million barrels of NGL in underground wells. It also features truck and rail loading facilities.

Contractors involved

McGuireWoods Consulting provided consulting solutions for the Lone Star Express pipeline project, while Stupp supplied high-strength steel for the Lone Star Express pipeline expansion project.

Natural gas liquid market in the US

The NGPL production in the US increased from 2.5 million bpd to 4.3 million bpd between 2012 and 2018, primarily driven by the production from tight rock formations developed using horizontal drilling and hydraulic fracturing techniques.

The major international challenge faced by the US NGL industry is the disruption caused by COVID-19 that has pulled the US and the Middle East in the oil price war. The US crude oil prices significantly dropped on falling gasoline demand, while the NGL products including ethane, propane, butane, natural gasoline have been affected with a varying degree of price shock from high to low.