The Liuhua 16-2 oilfield/ 20-2 oilfield joint development project, located offshore in the Chinese part of the South China Sea, came on stream in September 2020.

China National Offshore Oil Corporation (CNOOC) is the developer and operator of the project and holds a 100% stake in the fields.

The project is expected to reach the peak production capacity of 72,800 barrels of oil a day (bbd) in 2022.

It is claimed to be the first deep-water oil field development project independently implemented in China.

Location and discovery

The Liuhua 16-2 oilfield/ 20-2 oilfield joint development project is located in the Baiyun Sag in Pearl River Mouth basin, eastern South China Sea, China, approximately 240km south of Hong Kong. The water depth in the field area is approximately 410m.

Located in the Northern Slope Belt of Baiyun Sag, the Liuhua 20-2 structure was discovered by CNOOC in 2015. The discovery well encountered approximately 35.2m-thick oil pay zones in the Liuhua 20-2 structure.

Project layout

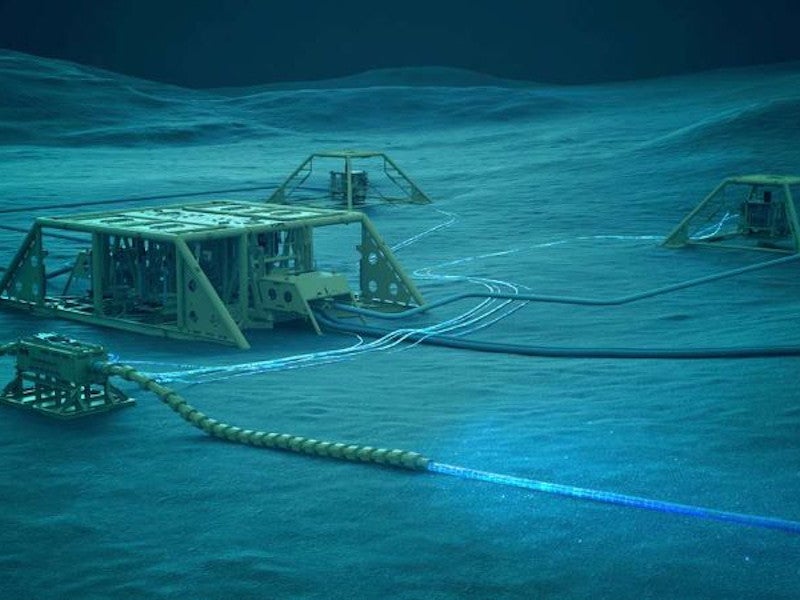

The Liuhua oil fields joint development project involves subsea development and tie-back to a floating production, storage, and offloading (FPSO) facility.

The project involves a total of 26 development wells and associated subsea equipment. The initial field development comprises three underwater production systems tied back to the FPSO.

FPSO details

The turret-moored floating production, storage, and offloading (FPSO) vessel deployed for the project is known as HAI YANG SHI YOU 119. The FPSO is anchored using nine suction pile anchors with chain-wire-chain legs.

The processing capacity of the FPSO is 21,000 cubic metres of crude oil a day and 540,000 cubic metres of natural gas a day. The FPSO is around 256m-long, 49m-wide, and 26.7m deep, while its deadweight tonnage (DWT) is approximately 150,000t.

The FPSO can operate at a water depth of 429m and has a design life of 30 years.

Subsea contractors involved

TechnipFMC bagged an engineering, procurement, and construction (EPC) contract for the subsea equipment for the project in May 2018. The scope of the contract included the supply of wellheads, subsea control systems, manifolds, tie-in systems, intervention workover control systems (IWOCS), and 26 units of enhanced horizontal christmas trees (EHXT).

Aker Solutions was awarded a contract worth more than £33m ($42m) to supply power umbilical systems for the project in August 2018. OsciLay manufacturing process was used for the production of static power umbilical. The length of the dynamic and static power umbilicals connecting subsea equipment to the FPSO is more than 115km.

COOEC Subsea Technology was contracted for the engineering, procurement, construction, and installation (EPCI) of subsea umbilicals, risers, and flowlines (SURF).

Ocean Installer was subcontracted by COOEC Subsea Technology to lay subsea power cable for the project in March 2020. The scope of the contract also included project management, engineering, transportation, and installation services.

Contracts awarded for the FPSO

Offshore Oil Engineering, a subsidiary of CNOOC, was responsible for the engineering, procurement, construction, and installation (EPCI) of the FPSO.

Qingdao Beihai Shipbuilding Heavy Industry was contracted to construct the hull of the FPSO in 2018.

Royal IHC was awarded the EPC contract for a comprehensive offloading system in June 2018. The contract included the supply of crude oil and LPG offloading reels, a tandem mooring system, a hydraulic power unit, and equipment controls for the FPSO.

InterMoor was subcontracted by Offshore Oil Engineering for the installation of deepwater mooring systems for the FPSO unit. The scope of work included project management, review and verification of detailed designs, detailed installation methodologies and procedures, installation engineering, and offshore preparation and execution.

TMC Compressors of the Seas (TMC) received a contract to supply the marine compressed air system for the FPSO in October 2018. The scope of the order included two 235kW instrument air compressors and a large adsorption air dryer with filters.