The Linden gas thermal power station is a 972MW natural gas-fired cogeneration facility producing both steam and electricity in Linden, New Jersey, US.

Owned and operated by Linden Cogen Holdings, the cogeneration complex comprises five gas-fired combined-cycle units commissioned in 1992 and the Linden-6 gas-fired unit commissioned in January 2002.

JERA Americas, a subsidiary of JERA Corporation, which is a 50:50 joint venture between Tokyo Electric Power (TEPCO) and Chubu Electric Power, acquired 50% equity interest in Linden Cogen to become the asset manager of the facility in April 2018. JERA acquired the stake from funds managed by Oaktree Capital Management, Ares Management, and their co-investors.

The other stakeholders in the operating company include Thailand-based Electricity Generating Public Company (EGCO, 28%) and the Development Bank of Japan (DBJ, 12%), while Korean independent power producer GS EPS, together with US-based private equity firm Platform Partners, holds the remaining 10% interest.

JERA announced to modify the Linden-6 gas-fired unit to enable the co-firing of hydrogen from the fuel gas supplied by the co-located Bayway oil refinery in July 2021. Scheduled for completion in 2022, the gas turbine modification will reduce the unit’s annual carbon dioxide (CO2) emissions by 10%.

Location and site details

The Linden gas-fired thermal power station is located adjacent to Phillips 66’s Bayway oil refinery complex in Linden, New Jersey, approximately 21km south-west of New York City.

Linden thermal power station make-up

The Linden combined heat and power station comprises six gas-fired units for an aggregate power output of 972MW.

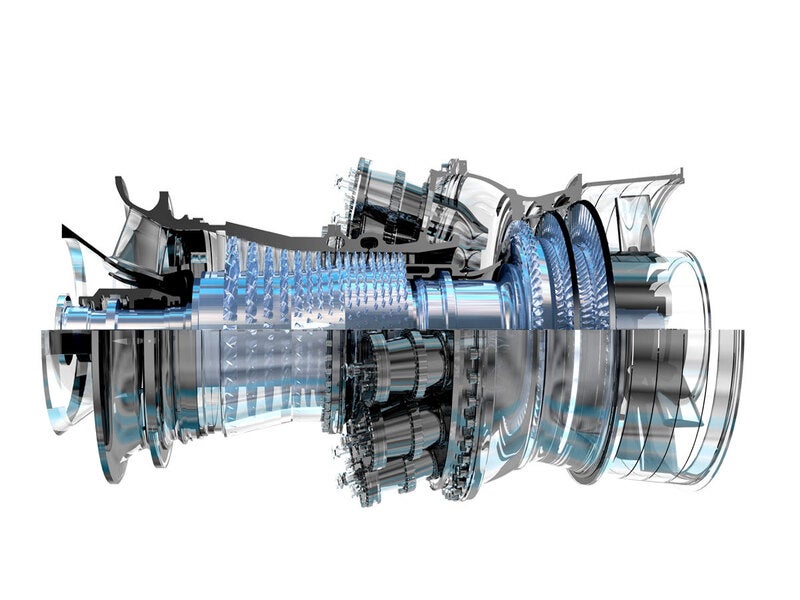

The Linden 1-5 combined-cycle units are equipped with five General Electric (GE) 7EA gas turbines, three D11 steam turbines, and five heat recovery steam generators (HRSGs) for a combined power output of 800MW. All the five units are designed to operate on natural gas as well as butane.

The Linden-6 unit, operating on natural gas as well as distillate, is equipped with a 172MW GE 7FA gas turbine connected to an HRSG.

Each unit of the Linden thermal power station is furnished with a selective catalytic reduction (SCR) system to reduce nitrogen oxide (NOx) emissions.

Linden-6 modification details

The Linden-6 gas-fired unit is being modified to add mixed fuel combustion capability including up to 40% hydrogen.

Linden Cogen signed an agreement with Phillips 66 to receive the supply of hydrogen-containing fuel gas produced by the Bayway oil refinery in July 2021.

The existing gas turbine will be retrofitted with the FlameSheet™ combustion technology from PSM, a subsidiary of South Korea-based Hanwha Group.

Incorporating a two-in-one can-annular combustor design, the innovative combustion system allows gas turbines to flexibly operate on blended fuel with reduced NOx and carbon monoxide (CO) emissions.

Steam and power offtake from the Linden cogeneration plant

The Linden thermal power station provides steam as well as electricity to the Bayway oil refinery under long-term supply agreements with Phillips 66.

It also supplies power to the New York Independent System Operator (NYISO) and the Pennsylvania-New Jersey-Maryland (PJM) Interconnection.

Power evacuation

The electricity generated by the Linden 1-5 block is evacuated into the NYISO Zone J (New York City) through a 345kV transmission line, while the electrical output of Linden-6 is fed into the PJM power markets through a 230kV transmission line.

Natural gas supply to the Linden power station

The Linden 1-5 block requires approximately 172,000 dekatherms of natural gas a day (dth/day), while Linden-6 consumes up to 45,000dth of natural gas a day.

The power station is supplied with natural gas through two separate gas pipelines comprising 14in, 12in, and 8in supply headers.

The Linden cogeneration facility was earlier connected through a single natural gas supply pipeline, which was replaced by two new independent gas supply lines to allow fuel supply flexibility for both the blocks of the plant in 2017.

The pipeline modification project also involved the installation of two separation isolation skids and a metering station.

Contractors involved

General Electric (GE) supplied the gas and steam turbines, while Nooter Eriksen delivered HRSGs for the Linden cogeneration facility.

Sargent and Lundy was contracted to provide engineering, procurement, and construction management services for the two new gas pipelines and the metering station in 2016.