La India gold-silver project is an open-pit mine located in Nicaragua. Condor Gold fully owns the project and is developing it with an estimated cost of approximately £70m ($110m).

Pre-feasibility study (PFS) for the project was completed in November 2014, while the environmental permit was granted in August 2018.

The project will have capacity to process up to 2,300 tonnes per day (tpd) of mineralised ore and produce 79,300 ounces (oz) gold a year. It is estimated to have a mine life of eight years.

La India gold-silver project location, geology, and mineralisation

The mining district is part of a 588km² concession package, fully owned by Condor. The concession is made up of 12 contiguous concessions, eight of which were directly awarded by the government and the remaining four were acquired from other owners.

Project Gallery

-

Environmental permit for the La India gold-silver project in Nicaragua was granted in August 2018. Image courtesy of Condor Gold.

-

The project holds 6.9 million tonnes (Mt) of probable reserves. Image courtesy of Alchemist-hp.

-

The La India project is expected to produce an average of 80,000 tonnes of ore a year. Image courtesy of Alchemist-hp.

The mineral concessions extend in various municipalities across Leon Department, Matagalpa Department, and Esteli Departments of Nicaragua.

The La India mining district is situated within a tertiary-aged island arc volcanic setting formed on the Caribbean Tectonic Plate’s edge.

Low sulphidation epithermal quartz vein and quartz breccia gold mineralisation is identified at La India.

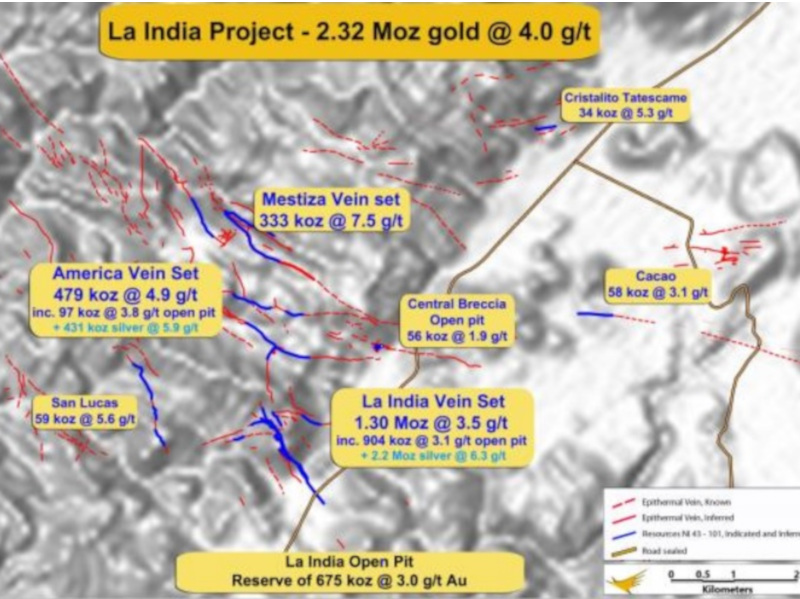

La India gold-silver project reserves

The La India gold-silver project is estimated to contain probable ore reserves of 6.9Mt, grading 3.0 grams per tonne (g/t). It is estimated to contain 675,000 ounces (koz) of gold and 1.19 million ounces (Moz) of silver.

Mining at La India gold-silver project

The La India gold-silver project will be mined using open-pit mining method, with the help of a cut-and-fill access ramp to access the upper levels of the mine. The project also proposes to use underground mining method at a later stage of development.

Major mining fleet will comprise a Komatsu PC1250 waste shovel, Caterpillar 777F haul trucks, Caterpillar 390 loading unit, and Caterpillar 773F haul trucks.

Processing at La India gold-silver project

The processing plant at La India project will have a capacity of 800,000tpa. It will feature a single-stage semi-autogenous grind (SAG) comminution and conventional carbon-in-leach (CIL) circuit.

Ore will be initially dumped into a ROM bin and then fed to a jaw crusher before conveying to the SAG mill.

The SAG mill will operate in closed circuit with cyclones and produce a required grind size, which will be thickened in a pre-leach thickener. The product will be then forwarded to the CIL circuit, which comprises one leach tank and six adsorption tanks, wherein gold will be adsorbed onto activated carbon.

Gold from the loaded carbon will be recovered in an elution circuit and then forwarded to electro winning and smelting processes to produce dore bar.

Infrastructure facilities

Power for the La India project is proposed to be supplied from a 138 kilovolt (kV) transmission line owned by Nicaraguan National Transmission Company. A tie-in and 138/11kV transformer, and associated switchgear will be installed as part of the project.

A purpose-built accommodation block will be built for senior and mid-level management, near the operations unit.

The site infrastructure will comprise a single-storey administration building, explosives storage facility, and a mine maintenance area.

Contractors involved

SRK Consulting prepared the PFS for the La India gold-silver project, while Lycopodium is responsible for engineering design of the processing plant and capital cost estimate for the PFS.