The Kola project is a sylvinite deposit under development in the Sintoukola Basin in the Republic of Congo.

Kore Potash holds 97% ownership of the Kola potash project through its subsidiary Sintoukola Potash (SPSA), while the remaining stake of 3% is owned by Les Establissements Congolais MGM.

SPSA owns a 100% stake in Kola Potash Mining (KPM), which holds the Kola mining lease. In March 2020, the Minister of Tourism and Environment of the Republic of Congo approved the environmental and social impact assessment (ESIA) of the Kola mining licence for a period of 25 years.

The definitive feasibility study (DFS) for the Kola potash project was released in January 2019. The study considers an underground mining method for the project.

Kore Potash signed a Memorandum of Understanding (MoU) with the Summit Consortium for the optimisation, construction and financing of the Kola project in April 2021.

Later, the company published an optimisation study in June 2022, outlining a reduction in the total investment for the project by $520m to $1.83bn compared to the $2.35bn capital cost estimated in the DFS.

The Kola potash project is expected to produce up to 2.24 million tonnes per annum (Mtpa) of granular muriate of potash (MOP) over an initial mine life of 31 years.

Location and site details

The Kola potash project is located in the Kouilou province, approximately 70km north of Pointe Noire city in the Republic of Congo.

The project is accessible from the port city of Pointe Noire, through the existing National Highway routes via Madingo Kayes.

Geology and mineralisation

The Kota potash seams are hosted by the Lower Cretaceous-aged Loeme Evaporite formation, which is 300-900m thick and belongs to the Congo (Coastal) Basin.

A thick sequence of carbonate rocks and clastic sediments of Cretaceous age to recent (Albian to Miocene) occurs over the evaporate formation. The thickness of the cover sequence is between 170 and 270m over the Kola deposit.

The Kola sylvinite deposit consists of flat or gently dipping seams located at depths ranging from 180 to 300m underneath the surface.

The seams include Hangingwall Seam (HWS), Upper Seam (US), Lower Seam (LS), and Footwall Seam (FWS), which are separated by Rock-salt.

The US and LS are the widely distributed Sylvinite seams at the Kola deposit, with an average grade of 35.5 and 30.5 % KCl, respectively. The seams have an average thickness of 3.7 and 4.0m.

Mineral Reserves of Kola project

The Kola sylvinite deposit was estimated to contain proved and probable reserves of 152.4Mt grading 32.5% potassium chloride (KCI), as of June 2022.

Total measured resources were estimated to be 215.7Mt grading 35% KCI, while indicated and inferred resources stood at 340Mt grading 34% KCI.

Kola project mining method and ore processing

The Kola potash project is expected to employ a conventional mechanised underground mining method, utilising vertical shafts to access the mine. Continuous Miner (CM) machines of the drum-cutting type are expected to be deployed to mine the orebody.

The mined ore is planned to be transported to the surface through an exhaust shaft fitted with a pocket lift conveyor system. The ore transportation to the shaft will be carried out using underground conveyor belts. Later, an approximately 25km-long overland conveyor will deliver the extracted ore to the processing plant.

The ore will then undergo crushing and a conventional flotation process will be employed by the plant to produce the potash concentrates. No separation process will be used due to low insoluble material.

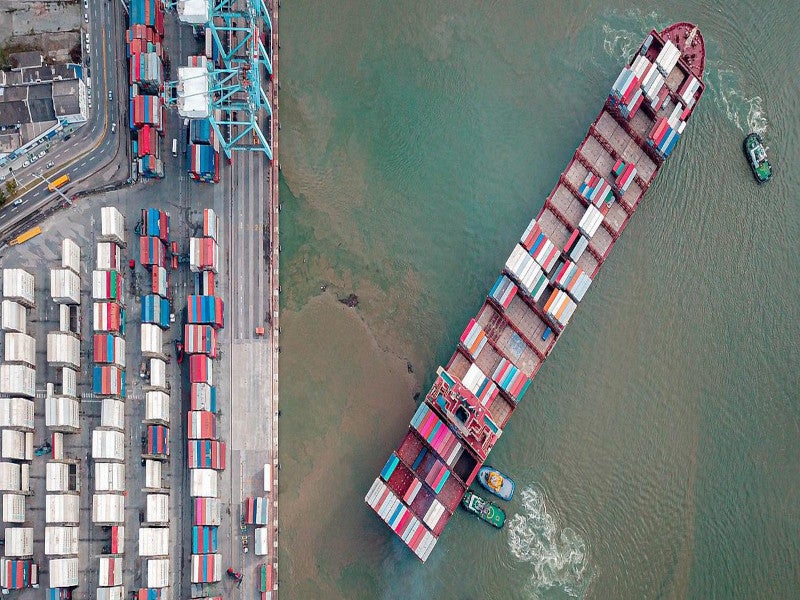

Upon the completion of the processing, the final MoP product is delivered to the marine export facility, located 11km from the plant, through a conveyor. The product from the storage area at the facility will be later transhipped into export vessels, utilising a dedicated barge loading jetty.

Infrastructure facilities

The Kola potash project will consist of infrastructure such as a mineral processing plant, permanent accommodation camp, administrative camp, solid waste management centre, access roads, and power, water and communication facilities.

The other infrastructure facilities will include maintenance roads for long-distance belt conveyors, a product and marine export facility at the coast, a gas pipeline, power transmission lines, and transshipment facilities.

Water, power and gas supply

The Kola project will meet its water requirements from the raw water wells located at the mine site and near the processing plant.

The project will be supplied with electricity from the national grid in the country, through a 57km-long 220kV transmission line that will be laid between the processing plant and the Mongo Kamba II substation located north of Pointe Noire.

A 73km-long pipeline will deliver the natural gas required for product drying from the M’Boundi gas treatment plant.

Contractors involved

SEPCO Electric Power Construction Corporation was engaged to carry out the optimisation study for the Kola potash project.

China ENFI Engineering was subcontracted by SEPCO to conduct a review of the mining, processing and infrastructure aspects of the potash project, whereas CCCC-FHDI Engineering was subcontracted for the marine facilities optimisation.

A consortium of French companies consisting of Technip France (TPF), Vinci Construction Grands Projets (VCGP), Egis International (EGIS) and Louis Dreyfus Armateurs (LDA) was engaged to undertake the DFS for the project.

SRK Consulting (UK) was contracted for the ESIA of the project.

Met-Chem DRA Global was selected by Kore Potash to prepare the mineral resource estimate.