The Josemaría copper-gold project is a major open-pit mining development in the San Juan province of Argentina. The project is being developed by Josemaria Resources which holds a 100% interest in the copper-gold-silver asset through its subsidiary Desarrollo de Prospectos Mineros.

The Josemaria deposit was discovered during an initial drilling campaign by NGEx Resources in 2004, while NGEx Resources changed its name to Josemaria Resources in July 2019.

The feasibility study (FS) report for the project was published in November 2020, and the environmental and social impact assessment (ESIA) is currently underway with completion expected by the first quarter of 2021.

The total capital investment for the Josemaria project is estimated to be approximately £2.3bn ($3.09bn). The project is expected to produce an annual average of 131,000 tonnes (t) of copper, 224,000 ounces (oz) of gold, and one million ounces (Moz) of silver over an estimated mine life of 19 years.

Location, geology, and mineralisation

The Josemaria copper-gold project is located in the San Juan province of Argentina, approximately 9km away from the Chile-Argentina border. The mining property covers a total area of approximately 16,425ha.

The Josemaria deposit is mainly composed of volcaniclastic and ignimbritic rhyolites including granites, underlain by the Permo-Triassic rocks of the Choiyoi Group.

The rhyolite and granite sequences are intruded by Triassic intrusive complexes of tonalite, diorite, and granodioritic composition.

The copper-gold mineralization at Josemaria occurs as a porphyry system hosted by Late Oligocene porphyry within the Permian to Triassic basement rocks. The deposit encompasses an area of 1500m north-south by 1,000m east-west with a vertical depth of up to 700m from the surface.

The southern region of the ore body is open and overlain by a thickening cover of post-mineral volcanic rocks extending to depth.

Ore reserves at Josemaria

The proven and probable ore reserves for the Josemaria project were estimated to be more than one billion tonnes (Mt), grading 0.30% Cu, 0.22g/t Au and 0.94 Ag, as of September 2020.

The mine is estimated to contain up to 6.7 billion pounds of copper, seven million ounces (Moz) of gold, and 30Moz of silver in proven and probable reserves.

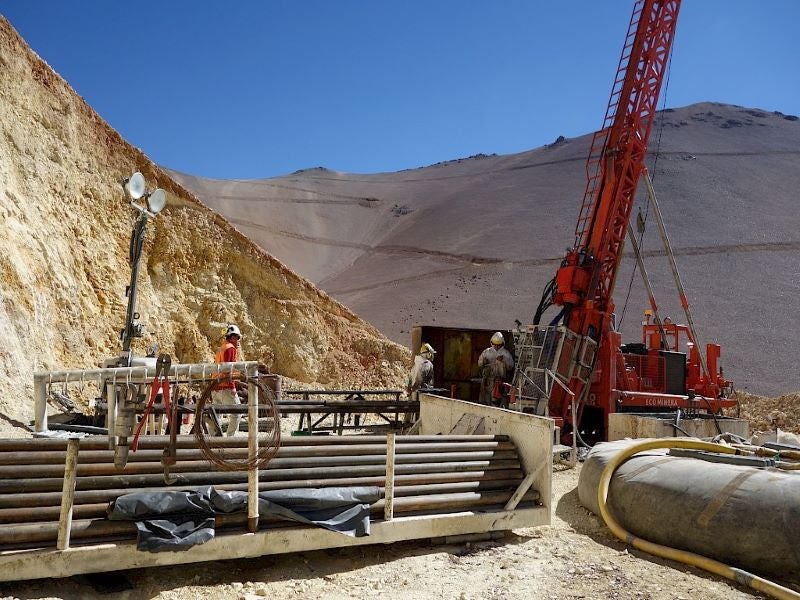

Mining methods

The Josemaria copper-gold project will utilise open-pit mining in 15m benches with average slope angles of up to 43 degrees.

The mining fleet will include electrically-powered hydraulic shovels supported by 360t haul trucks. Autonomous hauling and drilling techniques are planned to be incorporated as much as possible to maximize productivity, efficiency, and safety.

The in-pit haul roads will be 40m-wide while the ex-pit haul roads will be 45m to facilitate dual-lane operation for 363t autonomous haul trucks.

Mineral processing

The Josemaria processing facility will have a daily throughput rate of 150,000 tonnes per day (tpd) for hard tonalite ore, and 160,000tpd for the softer ores.

The run of the mine (ROM) ore will be introduced into the primary crushing and coarse ore handling circuit comprising two 1600mm x 2260mm Metso Mark III gyratory crushers and a 1.8 km conveying system connecting to a 60,000t ore stockpile facility.

The stockpiled ore will be fed into three identical semi-autogenous (SAG) grinding circuits and three corresponding ball milling circuits. The cyclone overflow from the ball mill will be introduced into the rougher-scavenger flotation cells to produce a copper concentrate and is transferred to the regrind circuit.

The flotation and regrind facilities will be housed in a single enclosed building and comprise rougher-scavenger flotation, regrind milling, and cleaner flotation circuits.

The rougher tailings will be passed through a sampler and onward to two 90m-diameter tailings thickeners, while the final concentrate from the cleaner flotation circuit will be pumped into a high-rate copper concentrate thickener, and will be filtered, dewatered, and stored at the site.

Concentrate transport from the Josemaria mine

The copper concentrate will be transported to a new road-to-rail intermodal facility near the Albardon Station, San Juan, from where the concentrates will be transported by rail to the Port of Rosario for export to smelters in Asia, Europe, and other South American regions.

The road-to-rail intermodal facility at Albardon will include a 15,000t concentrate storage shed, a scale, and a cleaning bay. A 45.000t storage shed will also be constructed at the Port of Rosario.

Infrastructure facilities

The Josemaria copper-gold project will be accessed through a 244km planned access road from the south via Rodeo.

The project site is planned to receive power supply through a 252km-long, 220kV, single-circuit transmission line connecting the substation at Rodeo.

The source of water for the project will be two groundwater well fields located approximately 25km away from the plant site.

A 250-person exploration camp currently exists at the project site, while a new accommodation camp will be constructed to house approximately 4,800 people.

Contractors involved

SRK Consulting prepared the feasibility study report as well as provided the mining, geotechnical engineering, and project economics consulting service for the Josemaria copper-gold project.

Fluor Canada provided the consulting services for the processing and infrastructure facilities, while Knight Piésold was engaged as the tailings management consultant during the feasibility study.

Fluor was engaged for the on-site electrical design while the off-site power supply design was developed by ESIN, a local electrical engineering firm.