Horne 5, owned by Falco Resources, is a gold deposit located in Rouyn-Noranda region of Quebec, Canada, underneath the historic Horne mine operated by Noranda between 1927 and 1976. The Horne mine produced more than 54 million tonnes (Mt) of ore during its mine life.

Falco acquired the Horne 5 project from Glencore Canada Corporation (Glencore) in 2011. Glencore retained a back-in right option as part of the acquisition, but later decided not to exercise the option, leaving full ownership of the deposit to Falco in September 2016.

Glencore retains a 2% net smelter royalty (NSR) on all metals produced from the Horne 5 deposit.

Feasibility study of the project was completed in October 2017, while construction is scheduled to begin in 2019. Falco aims to commission the processing plant in the first half of 2021 and pour first gold in late-2021, while full production is expected to be reached in 2022.

The Horne 5 gold deposit is expected to produce 3.3 million ounce (Moz) of gold or 5.1Moz of gold-equivalent over its estimated 15-year mine life.

The project is expected to create approximately 800 jobs during construction and 500 operational jobs.

“The Horne 5 deposit is estimated to contain proven and probable ore reserves of 80.9Mt .”

Horne 5 gold project geology and mineralisation

The Horne 5 deposit is located within the Abitibi terrane in the Archean Superior Province, which is host to some of the richest mineral deposits of the Superior Province including the Kidd Creek sulphide deposit.

The deposit lies within the east-trending segment of felsic volcanic rocks, which are an integral part of the Horne Block in the Blake River Group. The stratigraphy of the deposit strikes approximately west-northwest plunging steeply to the north.

The orebodies in the deposit submerge within rhyolitic flows, breccias and tuffs, and comprise least-altered rhyolites with low K2O contents and other geochemical features.

Horne 5 project reserves

The Horne 5 deposit is estimated to contain proven and probable ore reserves of 80.9Mt at an average grade of 2.37g/t of gold-equivalent. It is estimated to contain 6.13Moz of gold-equivalent.

Mining at Horne 5 gold deposit

Transverse long-hole stoping method of mining is proposed to be used at the underground deposit, which is located at a depth ranging from 600m to 2,300m below surface. Paste backfill will be used to fill the extracted stopes to ensure stability.

A 1,200m-deep existing shaft, Quemont 2, will be rehabilitated for transferring the mineralised material, waste, and services personnel, as well as for ventilation.

Mining will be undertaken in two phases, with the first phase running from 2021 to 2028 to extract 43.2Mt of ore at a rate of 15,700 tonnes per day (tpd). The second phase, from 2029 to 2035, is expected to extract 37.7Mt at a rate of 15,300tpd.

Automated and remote-controlled equipment will be used for conducting underground operations from the surface. The mining fleet will include 34 units including load/haul/dump machines, trucks, five 21t scoops, five 17t scoops, four 50t mine trucks, and other equipment.

Ore will be transported to the underground crushing facility through two ore pass systems and will be conveyed to the Quemont shaft.

“The Horne 5 project in Rouyn-Noranda will benefit from the existing mine infrastructure of the historic Quemont and Horne mines.”

The crushed material will then be transported by two 250m conveyors and transferred further to the shaft loading point by a 600m conveyor. It will then be hoisted to the surface using 43.5t skips on a continuous basis.

Ore processing at Horne 5

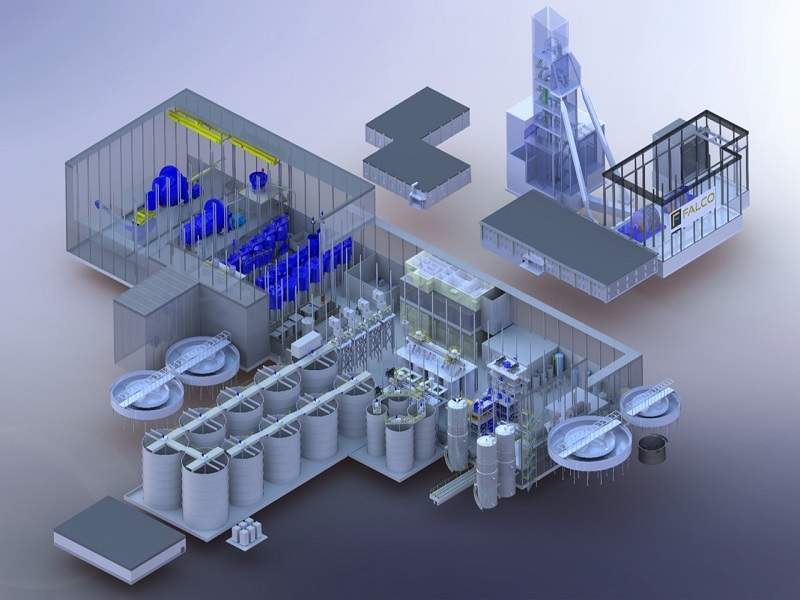

The processing plant will include a 15,000tpd conventional semi-autogenous-ball milling-crushing (SABC) circuit on surface for processing the crushed ore.

The milled ore will pass through three selective flotation circuits for recovering copper, zinc and pyrite concentrates. The copper and zinc concentrates will be stored directly in trucks and railcars before shipping.

The pyrite concentrate will undergo cyanide leaching to obtain a P80 size of 12 microns. It will then be leached along with the flotation tailings in separate leaching circuits. The resultant product will be transferred to the carbon-in-pulp (CIP) circuits before production of final gold silver doré.

Infrastructure at Horne 5 project

The Horne 5 project in Rouyn-Noranda will benefit from the existing mine infrastructure of the historic Quemont and Horne mines. The mine can be accessed either from Route 101 or from the Trans-Canada Highway.

Electricity will be supplied to the site through Hydro-Quebec’s Rouyn-Noranda substation, which is located 1km away.

The mine will also include supporting infrastructure such as site access roads, maintenance shop and warehouse, mine office and administration building, and railway spur lines.

Contractors involved

BBA prepared the feasibility study for the underground gold project, with support from a group of consulting firms including Golder Associates, InnovExplo, SNC-Lavalin Stavibel, and Ingénierie RIVVAL.

WSP Canada prepared the environmental impact assessment study.

Falco reached an exclusive agreement with ABB Canada for the supply of hoisting systems for the project.

Sandvik Mining and Rock Technology were contracted for the supply of mining equipment. The contractual scope also includes supply of AutoMine® Loading system, which enables multiple loaders to operate in separate production areas from a single operator station.