The Heartland complex is a petrochemical plant currently in the initial production stages in Alberta, Canada. The complex is the first integrated propane dehydrogenation (PDH) and polypropylene production plant in the country.

Inter Pipeline is the developer and operator of the petrochemical complex. Brookfield Infrastructure acquired Calgary-based Inter Pipeline in October 2021.

Construction on the Heartland complex commenced in early 2018 and the facility is estimated to be built with a total investment of approximately £2.7bn ($3.2bn). It was awarded a grant of around £264m ($312m) under the Alberta Petrochemicals Incentive Program (APIP) in April 2021.

Inter Pipeline commissioned the polypropylene plant at the complex in July 2022, utilising polymer grade propylene (PGP) feedstock from a cavern at its Redwater Olefinic Fractionator (ROF).

At full capacity, the Heartland Petrochemical Complex is expected to produce 525,000 tonnes per year of polypropylene by converting propane that will be sourced locally. Polypropylene is a plastic that is used in the manufacturing of food packaging, textiles, automobile components, healthcare products and medical supplies.

Location and site details

The Heartland Petrochemical Complex is located in Strathcona County, northeast of Edmonton, Alberta, Canada.

Occupying an area of 94ha, the project site lies within the Alberta Industrial Heartland (AIH) with access to a network of rail and storage terminals.

Heartland Petrochemical Complex details

The Heartland Petrochemical Complex comprises a PDH facility, a polypropylene production plant, a cogeneration plant and a rail yard.

The PDH facility will be the main source of feedstock for the polypropylene plant by converting propane into propylene, which will be used to produce various grades of polypropylene. It is expected to have a capacity to convert 22,000 barrels per day of propane into 525,000 tonnes per year of PGP.

The cogeneration facility, which will serve as a central utilities block (CUB), will produce steam, electricity, and other utilities required for the petrochemical complex.

A rail yard will be constructed as part of the petrochemical project for the transportation of the produced polypropylene to domestic and international markets.

The Heartland Petrochemical Complex is expected to benefit from the flexibility in feedstock supply from the onsite propylene production and the 600,000 barrel PGP storage cavern located at the Inter Pipeline’s ROF connected through a pipeline.

The complex will utilise UOP Oleflex technology for PDH processing and Grace UNIPOL to process polypropylene.

Central utility block (CUB) details

The CUB is a 102MW natural gas-powered cogeneration facility that will supply electricity, steam, and other utilities to the PDH and polypropylene plants.

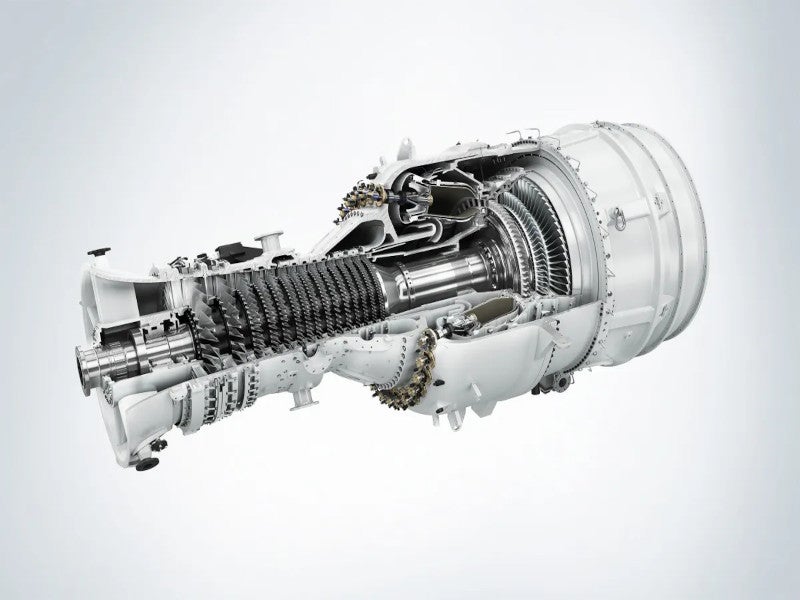

The block features two Siemens SGT-800 gas-fired turbine generators, two single-pressure heat recovery steam generators (HRSG), and two D-type water tube auxiliary boilers. It will also consist of a modular rack system, a water treatment plant and an Emergency power system.

It will be able to operate on natural gas and/or blended fuels that are rich in ethane or hydrogen.

Inter Pipeline sold the CUB to Fengate Capital Management (Fengate) in September 2018.

Heartland Petrochemical Complex rail yard

The Heartland petrochemical project will include the construction and operation of a rail yard within AIH.

Expected to cover an area of approximately 10ha, it will comprise a railcar loading facility and railcar storage yard. It will the construction of a rail line of up to 11km in length over 26 new onsite rail tracks.

The railcar storage area will have the capability to facilitate the loading of up to 24 cars per day and to store up to 200 loaded and empty cars.

Contractors involved

Waiward was contracted contract to carry out connection design, drafting, fabrication, and erection of 18,475 tonnes of structural steel for PDH area, polypropylene plant and the CUB at the Heartland Petrochemical Complex.

Becht Engineering was awarded an owner’s engineering quality assurance project for the petrochemical facility.

Fluor was engaged to conduct the detailed engineering and procurement for the PDH plant.

POWER Engineers was selected to provide design engineering services for the construction of the CUB. Fortress Engineering of Calgary was subcontracted by POWER Engineers for process safety analysis and CUB heat tracing coordination services.

Siemens was awarded a contract by Inter Pipeline to deliver long-term service for two SGT-800 gas turbine generator sets at the CUB in April 2018.

W. R. Grace was contracted to license its UNIPOL PP process technology for the Heartland Petrochemical Complex in April 2018.

Worley was awarded a master site services and supply contract by Inter Pipeline in January 2021. The contract included the delivery of commissioning support, direct hire maintenance, turnaround, engineering and consulting services.