He Dreiht is a 900MW offshore wind farm planned to be developed in the North Sea, Germany. It is one of the biggest offshore wind power projects planned in Europe.

Energie Baden-Württemberg (EnBW), an integrated energy utility based in Germany, proposes to build the wind farm with the latest generation 15MW offshore wind turbines.

He Dreiht will be the first zero-subsidy offshore wind farm in Germany. EnBW secured development rights of the project in Germany’s first competitive offshore wind energy auction held in 2017.

The final investment decision (FID) on the project is expected in 2023, with construction works planned to start in the same year. The offshore wind farm is anticipated to commence operations by the fourth quarter of 2025.

Location and site details

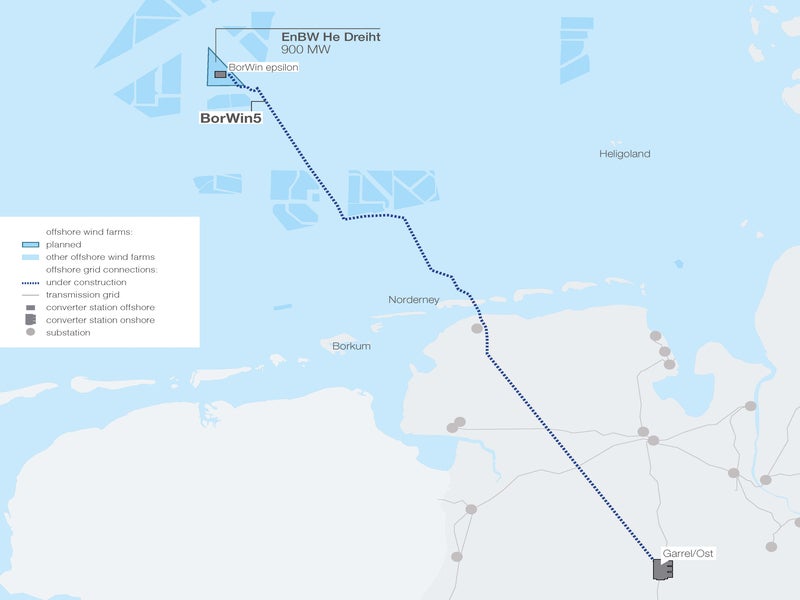

The He Dreiht offshore wind power project is located in the German waters of the North Sea, 90km north-west of the Borkum Island and 110km west of Heligoland Island.

The project site lies adjacent to the operational 497MW Hohe See and 112MW Albatros offshore wind farms.

He Dreiht offshore wind farm make-up

The He Dreiht offshore wind farm is planned to be installed with 60 Vestas V236-15MW wind turbines.

With a 236m-diameter rotor and 115.5m-long blades, each turbine will have a swept area of 43,742m2 and a rated power output of 15MW. The cut-in and cut-out wind speeds of the turbines will be 3m/s and 30m/s, respectively.

V236-15MW is claimed to be the world’s most powerful wind turbine design, with a single turbine unit capable of generating up to 80 gigawatt-hours (GWh) of electricity a year over its design life of 25 years.

Vestas V236-15MW turbine development details

Danish wind turbine manufacturer Vestas launched the V236-15MW offshore wind turbine in February 2021.

Vestas announced in October 2021 that the first V236-15MW prototype turbine is planned to be installed at the Østerild National test centre in Western Jutland, Denmark, in the second half of 2022. Serial production of the turbine is scheduled to begin in 2024.

Power evacuation from the He Dreiht wind farm

The electricity generated by the He Dreiht offshore wind farm will be evacuated through a 66kV alternating current (AC) transmission cable connecting the BorWin epsilon offshore high-voltage direct current (HVDC) converter station.

The direct current (DC) electricity will be transmitted through TenneT’s 230km-long BorWin 5 HVDC offshore grid connection system.

Planned for commissioning in 2025, BorWin 5 will comprise 110km of submarine cable and 120km of onshore cable from the landfall in Hilgenriedersiel to a converter station in Garrel/Ost near Cloppenburg.

Power purchase agreement

Fraport, the owner and operator of Frankfurt Airport, signed a 15-year power purchase agreement (CPPA) with EnBW in December 2021 to offtake 85MW of electricity a year from the He Dreiht offshore wind farm starting from 2026.

The renewable electricity will be used to operate three terminals, illuminate the airport’s apron and four runways, and charge more than 500 electric vehicles (EVs) on the airfield.

GÖRG Partnerschaft von Rechtsanwälten, a commercial law firm based in Germany, provided legal advisory services to Fraport on the PPA.

Contractors involved

Vestas was selected to manufacture and supply the wind turbines for the He Dreiht offshore wind farm in July 2021.

Jörss-Blunck-Ordemann (JBO), an engineering company based in Germany, was selected to provide the design of turbine foundation structures for the project in February 2021.

Bureau Veritas was contracted to provide certification services for the wind turbines and foundations of the He Dreiht offshore wind farm in December 2020.

IHC IQIP was contracted to provide a double-walled noise mitigation system called NMS-10,000 to reduce the noise created during the installation of monopiles for the project.

Moeller & Poeller Engineering (MPE) undertook the basic front-end engineering design (FEED) study for the offshore substation of the project in 2016.