The Dougou Extension is a sylvanite mine located in the Kouilou district of Democratic Republic of Congo.

Owned and operated by Kore Potash, the mine holds one of the world’s highest grade potash reserves. The mine is part of the Dougou Mining Lease, which is 100% owned by Sintoukola Potash SA (SPSA), a subsidiary of Kore Potash.

A scoping study for the prospect was completed in 2019 for a solution mining operation. A pre-feasibility study (PFS) was subsequently undertaken in 2019 and completed in May 2020.

The project is expected to have a low capital expenditure of $286m (£234m) with an estimated 21 months construction period. The project will produce 400ktpa of Muriate of Potash (MoP) over an 18 year mine life.

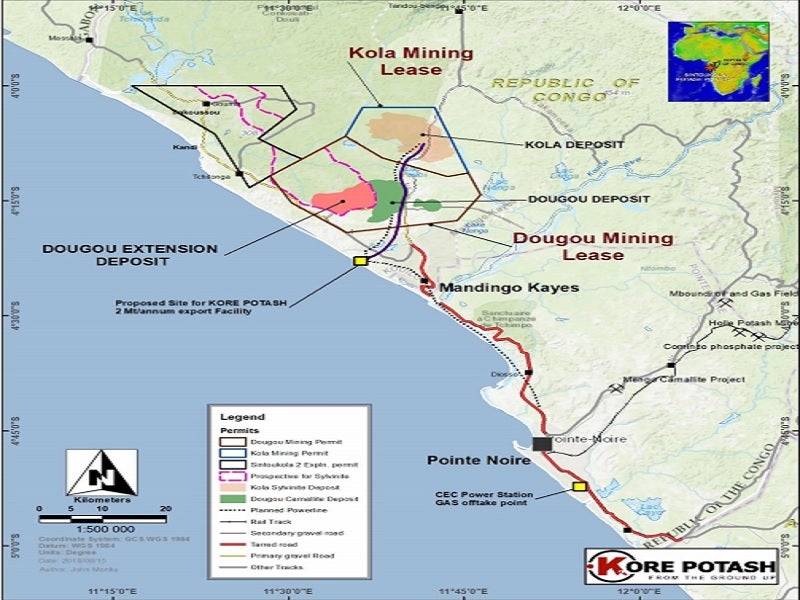

Project location and mineralisation

The Dougou Extension project is located within 20km of Kore Potash’s flagship Kola Sylvinite deposit (Kola) and occupies an area of approximately 10km x 15km.

The sylvinite deposit at the Dougou Extension project is hosted by two flat-lying or gently dipping seams. The seams are hosted by 400m-500m thick Loeme Evaporite formation of sedimentary evaporite rocks.

The seams are separated by 8m-15m of rock-salt. The uppermost seam is the Top Seam (TS) and the lowermost is the Hanging Wall Seam (HWS).

Resources and Reserves at Dougou Extension (DX) Project

As per the PFS, the mineral reserves at the Dougou Extension project are estimated at 17.7 million tonnes (Mt) grading 41.7% Potassium chloride (KCl) and 0.06% Magnesium (Mg).

The total indicated and inferred resources are estimated at 145Mt grading 39.7% KCl and 0.05% Mg.

Mining method

The Dougou Extension project will utilise single well, solution mining method with one well per cavern. The wells will be drilled to a depth of approximately 460m for areas where hanging wall seam solution (HWSS) mining is used. In the areas where top seam solution (TSS) mining is planned, the wells will be drilled to a depth of approximately 440m.

A brine saturated with halite (NaCl) will be used for the solution mining so that only the sylvite containing KCl and NaCl minerals is dissolved.

Surface casing will be installed at approximately 400m vertical, which is the top of the salt layer and an intermediate casing will be installed to the base of the HWSS. The single well caverns will feature a well radius of 60m.

The HWSS zone has a KCl content of 57.1%, which should facilitate selective mining. Mining of the TSS zone is more challenging as the halite interbeds will not be dissolved by the NaCl rich solvent to provide access to the overlying high-grade potash beds. The TSS mining plan is to selectively mine the high-grade beds and induce the low-grade beds to fall to the bottom of the cavern.

Production of KCl in the first seven years of operation will be 78.1% from the HWSS and 21.9% from the TSS.

Processing methods at Dougou Extension

The process plant will be located east of the Dougou Extension mine plan area and house all processing equipment, along with associated electrical and instrumentation.

The brine solution will be pumped to the surface crystallisers after being cooled to approximately 28°C in the vacuum crystalliser. The surface crystallisers will produce a slurry containing KCl solids precipitates. The slurry is pumped to the centrifuge to remove brine and produce a potash product with less than 5% moisture.

The potash product is introduced to a rotary drum dryer to further reduce the residual moisture in the potash product to 0.2% or less and produce a dried solid product.

Two compaction circuits each comprising of a compactor, flake breaker, hammer mill, sizing screen and a conveyance system will operate in parallel to properly size the product. The screen oversize will be returned to a hammer mill for further crushing.

The finished product will be transported to a glazing circuit to harden the particle surfaces and smoothen the sharp edges to avoid product degradation during transportation.

Granular MoP product from the glazing circuit will be treated with anti-caking and de-dusting reagents and transported through 150t storage bins by trailers to the marine storage facility located at Pointe Noire.

Infrastructure details

Dedicated pipelines will transport raw water from the sea through a permanent sea water intake to the process plan area. A pumping station and water supply pipeline connecting to the production wellfield will also be developed. Waste brine produced in the process plant is planned returned to the sea through a pipeline.

An 85km overhead high-voltage power transmission line will be developed from M’Boundi to the process plant to meet the electricity requirements of the mine.

Camp accommodation for 250 people will be provided during construction, while capacity will be reduced to 100 during operations.