The Copper World is an open-pit copper mining complex planned to be developed in Pima County, Arizona, US. Hudbay Minerals is the owner of the copper mining project.

Hudbay Minerals released the preliminary economic assessment (PEA) for the development of the mining complex in June 2022.

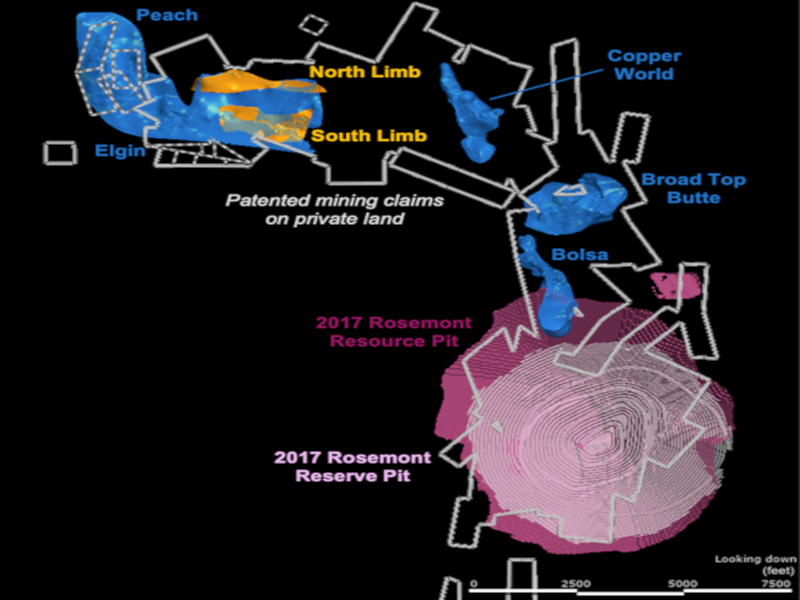

The complex comprises seven deposits that include Bolsa, Broad Top Butte, West, Peach, Elgin, South Limb and North Limb. It will also include the development of the Rosemont deposit.

The Copper World project will be developed in two phases and will include four open pit mines. Phase I development is estimated to require a total investment of about $1.9bn, with an annual copper cathode production of approximately 100,000 tonnes.

The Phase II project is expected to involve capital costs of $885m with an increase in production to 125,000 tonnes.

The Copper World Complex is expected to have an overall mine life of 44 years, with Phase I operations running for the initial 16 years and Phase II activity continuing for the remaining period.

The project will also produce molybdenum concentrate, silver and gold in doré and sulphuric acid as a by-product.

Location and site details

The Copper World Complex deposits are located within the historic Helvetia-Rosemont mining district, approximately 50km southeast of Tucson in Pima County, Arizona.

The project site lies on the northern block of the Santa Rita Mountain range and is accessible through South Santa Rita Road from Tucson.

Phase I operation of the project with processing infrastructure will be located on Hudbay’s private land and patented mining claims in the area, while Phase II mining activities will expand onto federal land.

Geology and mineralisation

The Copper World Complex deposits are situated in the porphyry province Laramide belt that stretches for approximately 1,000km from Arizona to Sinaloa, Mexico, and hosts many other major deposits, including Morenci, Resolution, and Cananea.

The deposits significantly contain Precambrian granite with a presence of Paleozoic and Mesozoic sediments and small stocks and dikes of quartz monzonite or quartz latite porphyry occurring in slices belonging to porphyry copper and skarn mineralisation.

The oxidation of the sulfides is observed at near-surface Paleozoic units at the Copper World deposits due to surface weathering.

Mineralisation at the deposits occurs as copper, molybdenum and silver-bearing sulfides, which are identified in stockwork veinlets, and distributed in the altered host rock below the surface.

Mineral Resources

The Copper World Complex was estimated to contain measured and indicated resources of 1,173Mt grading 0.41% Cu, as of June 2022.

Total Inferred resourced were estimated to be 262Mt grading 0.37% Cu.

Mining method and ore processing

The Copper World Complex will deploy a conventional shovel and truck method for the mining operation that is expected to consist of four open pits.

Milling, leaching, solvent extraction and electrowinning of both copper sulfide and oxides will be carried out to produce copper cathode and other products.

The processing facilities will include a 60,000 tonne per day sulfide concentrator, a concentrate leach facility, an oxide leach and solvent extraction and electro-winning (SX/EW) facility, and an acid plant. The concentrator capacity is expected to be expanded to 90,000 tonnes per day in the second phase.

The sulfide mill will include conventional crushing, grinding, flotation, molybdenum separation, concentrate dewatering and tailings dewatering. Haul trucks will be used to deliver the run-of-mine (ROM) sulfide feed to a primary crusher.

Processing of the sulfide concentrate produced in the mill will be carried out in the concentrate leach facility to produce a pregnant leach solution (PLS).

Later the treatment of the PLS that is combined with the solution from the oxide leaching circuit will be done in the SX/EW facility in copper cathode.

The concentrate leach facility is also expected to produce sulphur, which will be converted into sulfuric acid at the acid plant. The produced acid will be used on the oxide leach pads.

Waste rock and tailings produced during the mining and processing activities are proposed to be moved to the storage facilities.

Infrastructure facilities

The Copper World Complex infrastructure will consist of access and plant roads, electric power supply and distribution, water supply and distribution, voice and data communication, waste rock and tailings storage facilities, leach pads, and other ancillary facilities.

The other facilities will include a mine office building, explosives storage facility, truck shop, heavy equipment fuel storage and dispensing facilities, and light vehicle fuel station facility.

Water and power supply

Electricity for the Copper World Complex will be supplied by Tucson Electric Power (TEP) through a 138kV transmission line connected at the Toro Switchyard, which will be located in the private land parcel of Hudbay.

Water supply requirements will be met through groundwater in the basin-fill deposits of the upper Santa Cruz Basin, situated west of the project.

Contractors involved

Kappes, Cassiday & Associates (KCA), Laboratorio Metalúrgico Chapi (Chapi) and SGS were selected by Hudbay to conduct mineralogical and metallurgical testing on the Peach, Elgin and Broadtop Butte deposits.

Wood was engaged to provide pre-feasibility level pit slope design recommendations for the Peach-Elgin, Broadtop Butte and Copper World pits.