Cerro Blanco is a high-grade gold mining project planned to be developed by Entre Mares, a wholly-owned subsidiary of Bluestone Resources, in Jutiapa, Guatemala.

Feasibility study for the underground project was completed in January 2019, while environmental approval was received in 2007.

With an estimated pre-production capital investment of $196m, the Cerro Blanco project is forecasted to produce approximately 902,000oz of gold and 3.03 million ounces (Moz) of silver, processing 3.44 million tonnes (Mt) of ore over its initial eight years of mine life.

Cerro Blanco gold project background

Exploration activities on the Cerro Blanco gold project were initiated in 1998 by Mar-west, which transferred the project ownership to Glamis Gold in 2000.

Goldcorp acquired the exploration property from Glamis Gold in 2006 and spent more than $170m in exploration and development, before selling the project to Bluestone Resources in May 2017. Cormark Securities and Axium Law acted as the financial and legal advisors to Bluestone Resources for the Cerro Blanco acquisition.

Bluestone Resources commissioned the feasibility study of the project in September 2017.

Cerro Blanco location, geology, and mineralization

The Cerro Blanco gold-silver mining concession covers 15.25km2 in Asuncion Mita municipality of Jutiapa district in south-east Guatemala, approximately 160km away from the Guatemala City.

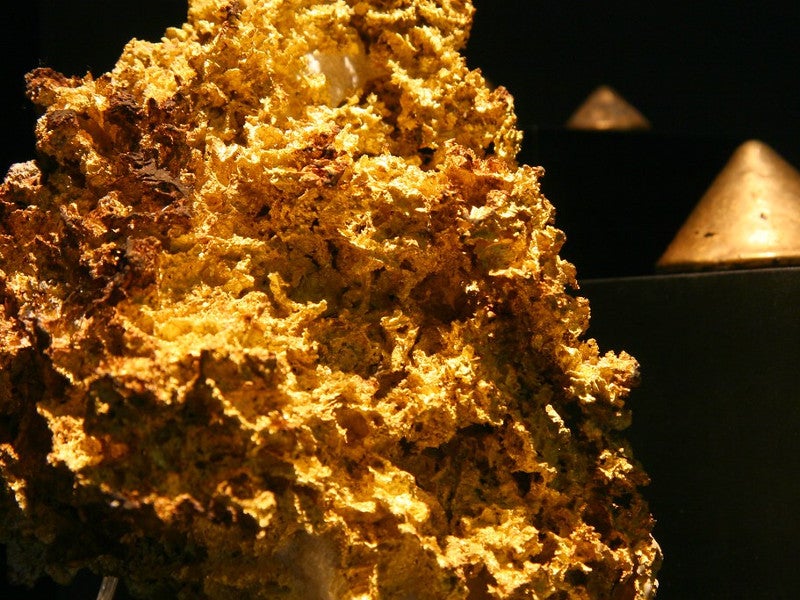

The Cerro Blanco gold deposit is found hosted in more than 50 individual veins over a strike length of 800m, within a 5km-long and 1km-wide hydrothermal alteration zone, which is associated with a hot springs-type epithermal system.

Mineralization occurs in siltstones, sandstones, and limestones that are overlain by silicified conglomerates and sediments with cryptodomes.

Ore reserves

The Cerro Blanco project is estimated to contain 3.44Mt of proven and probable ore reserves grading 8.5g/t Au and 32.2 g/t Ag and containing 940,000oz of gold ore and 3.5Moz of silver.

The project is also estimated to contain 1.2Moz of gold and 4.5Moz of silver in measured and indicated resources.

Mining and ore processing

Cerro Blanco will be an underground mining operation involving a combination of long-hole stoping (LH) and mechanized cut-and-fill (MCF) mining methods using cemented paste and rock backfill.

The underground mine infrastructure will include two underground declines, four ventilation shafts, 3.2km of lateral underground development, and 17 dewatering wells.

The run-of-the-mine (ROM) ore will be processed at a 1,250 tonnes per day (tpd) processing plant located nearby. The ore will pass through three-stage crushing, two-stage grinding, gravity separation, pre-leach thickening, and carbon-in-pulp (CIP) leaching, for the recovery of gold.

The Cerro Blanco project is estimated to produce 112,000oz of gold and 579,000oz of silver a year.

Infrastructure facilities

The project can be reached from the Pan-American Highway via a new 5km-long access road, which will involve the construction of a bridge over the Rio Grande de Mita River.

Electricity for the mine operations at Cerro Blanco will be supplied through an 8.2km-long, 69kV single-circuit overhead transmission line connecting the Energuate Barranca Honda substation.

Other infrastructure facilities of the project include a 3Mt drystack tailings facility (DSTF), a water treatment plant, and a 4MW emergency generator power supply facility.

Contractors involved

JDS Energy & Mining, an engineering and project management consultancy firm based in Vancouver, Canada, acted as the lead technical consultant and prepared the feasibility study for the Cerro Blanco gold project.

Kirkham Geosystems studied the deposit geology and provided mineral resource estimate, while Stantec Consulting provided designs for the drystack tailings, waste rock, and water management facilities for the project during its feasibility study phase.

Hatch Consulting provided site development plan and detailed engineering for the processing facilities, while Paterson & Cooke Canada was engaged for the engineering designs and cost estimates of dewatering and paste plants.