Bombore gold project is located approximately 85km east of Ouagadougou, in the Ganzourgou Province, Burkina Faso. It is one of the biggest undeveloped oxide gold deposits in West Africa.

Orezone Gold, which acquired the property in 2003, owns 90% interest, while the remaining 10% interest is owned by the government of Burkina Faso.

Orezone completed an updated feasibility study for the project in July 2018 and plans to commence construction in the first half of 2019.

The Bombore gold mine is expected to commence production by the end of 2010 with an overall plant throughput of 5.2 million tonnes per annum (Mtpa). It is expected to produce more than one million ounces (Moz) of gold over its estimated mine life of 13 years.

The initial project construction cost is estimated to be $143.7m.

Orezone commissioned a further updated feasibility study for the project in November 2018, to incorporate the Phase II Sulphide Expansion at Bambore.

Expected to commence commercial production in the third year of the current mine schedule, the expansion project will target the higher-grade sulphide ore lying beneath the oxide ore deposits, and replace the lower-grade oxide ore feed to the processing plant.

Bombore geology and mineralization

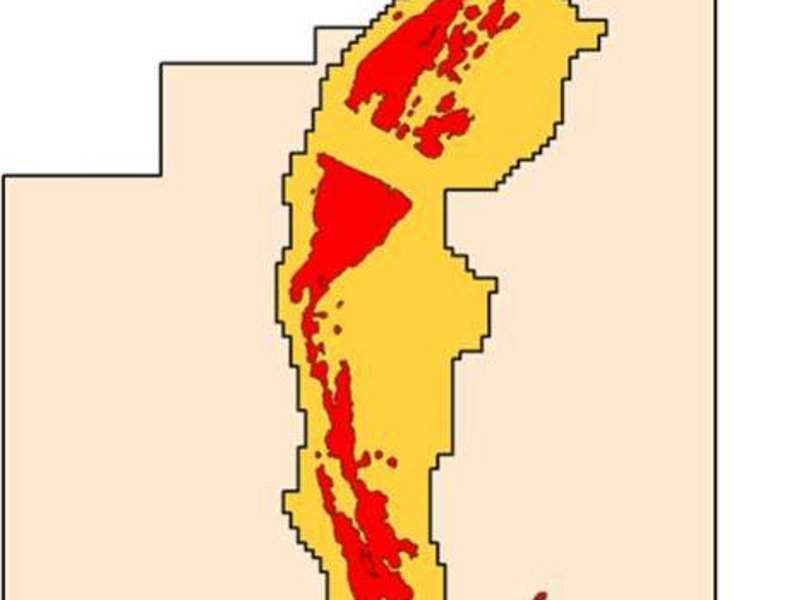

The Bombore gold project area occupies 15,029ha within the Tiebele-Dori-Markoye shear zone.

With a length of 14km and average width of200m, the Bombore shear zone substructure represents the biggest gold-in-soil anomaly in Burkina Faso.

The gold mineralization in the Bombore shear zone is associated with silica, sulphide, as well as minor arrays of quartz veins and veinlets. It’s mostly found disseminated in pyrite, chalcopyrite arsenopyrite, and stringers.

Bombore gold project reserves

The Bombore gold project was estimated to contain 56Mt of proven and probable ore reserves grading 0.64g/t gold, as of July 2018.

Mining and ore processing for the Bombore project

Bombore will be a shallow, free-dig open- pit mining operation involving excavators of 3m³ to 6m³ capacity and highway dump trucks of capacity between 30t and 50t.

The run-of-mine ore will be hauled to the nearby processing plant where it will undergo single-stage ball mill grinding and hydrocyclone separation before entering the seven-stage carbon-in-leach (CIL) circuit.

The obtained leach material will further pass through a pressure Zadra elution circuit. The soluble gold from the pregnant eluate will be recovered by electrowinning onto stainless steel cathodes.

The gold sludge will then be washed off the cathodes, and filtered, dried, and smelted to produce dore ingots.

The Bombore phase II sulphide expansion project will involve the addition of a separate small crushing and grinding circuit without any other expansion or upgrade to the original processing infrastructure.

Infrastructure facilities for the Bombore gold project

The Bombore gold mine site is accessed from the Ouagadougou city via a paved road connecting the N4 national highway.

The average power load for the gold mine operation is estimated to be 5.45MW, which will be supplied by an on-site heavy fuel oil-based power plant.

The mine will use fresh water from the Nobsin River as well as the decant water from the on-site tailings management facility (TMF).

Contractors involved

Lycopodium Minerals was the front-end engineering and design (FEED) contractor and acted as the lead study manager for the project’s updated feasibility study, which was completed in 2018.

AMC cConsultants provided the mineral reserves estimate for the project during its feasibility study, whereas Roscoe Postle Associates (RPA) provided mineral resources estimate along with geological consulting services.

Knight Piesold Consulting (KPC) provided the design for the tailings storage facility as well as the water management and supply system.

The same consultants have been retained for the feasibility study of Bombore phase II sulphide expansion project.

SRK Consulting was engaged for the mineral resource estimates for the project prior to 2013, whereas Kappes, Cassiday and Associates (KCA) were engaged in preparing a feasibility study in 2014.

The geotechnical study for the project was carried out by Golder Associates.

The preliminary economic assessment (PEA) for the Bomber gold project was completed by G Mining in 2012.