The Block 14 gold project is located in the northern part of the Republic of Sudan, in close proximity to the Egyptian border. The project is being developed by Orca Gold, a mineral properties explorer and developer based in Canada.

Preliminary economic assessment (PEA) of the gold project was completed in July 2016, while feasibility study was completed in November 2018.

The project development is estimated to cost $328m (£254.54m). It is expected to produce an average of 167,000oz of gold a year through its anticipated life of mine of 13.5 years.

Block 14 gold project location, geology, and mineralisation

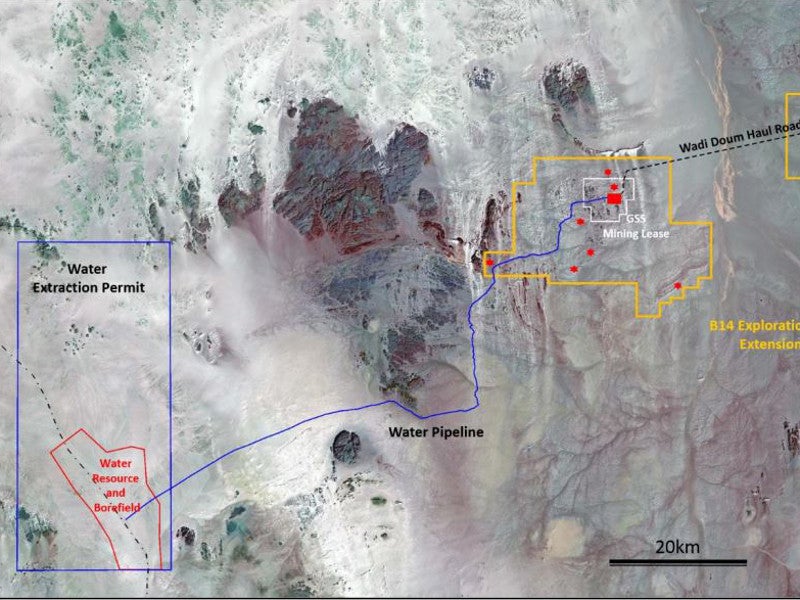

The Block 14 mineral exploration project lies in the Nubian Desert, north of the Republic of Sudan over 2,170km². It lies approximately 700km north of the national capital, Khartoum. The landscape is characterised by rocky hills separated by wide, flat sand filled drainage channels.

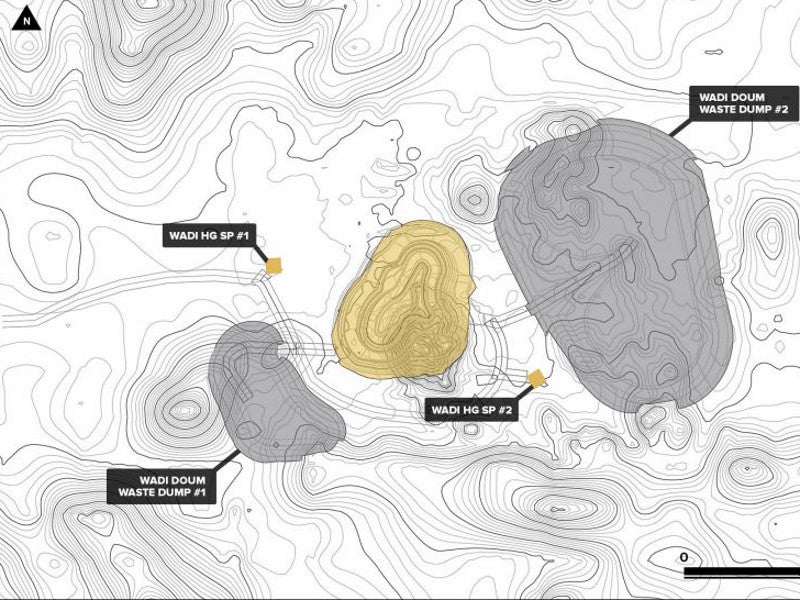

The project comprises two deposits namely Galat Sufar South (GSS) and Wadi Doum, which were discovered in 2012 and 2014, respectively. The deposit is identified in the central portion of the Galat Sufar Andesite Domain, an anomalous exposure within the Keraf sediments. The mineralisation is concentrated in a discrete 80-200m-wide volcaniclastic‐sedimentary horizon containing dioritic sills.

Wadi Doum hosts high-grade mineralisation in a strong sulphidic volcaniclastic unit, which dips at an angle of 20° to the south-west. The gold mineralisation is associated with stringer zones and smaller shears.

Pyrite is the most dominant sulphide at Wadi Doum and accounts for up to 85% of the mineralisation, while the remainder comprises a mix of sphalerite, galena, chalcopyrite, and freibergite.

Block 14 comprises an andesite, which is dominated by the eastern Gabgaba terrain of the Arabian Nubian Shield (ANS) on the east and the Keraf Suture to the west.

Gold mineralisation at Block 14 is categorised into three groups namely orogenic gold, volcanogenic massive sulphide, and rift-associated epithermal.

Block 14 gold project reserves

As of November 2018, the mineral reserves at Block 14 were estimated to be 79.94Mt grading 1.11g/t of Au. Contained gold is estimated to be 2.85 million ounces (Moz).

Mining and ore processing at Block 14 gold project

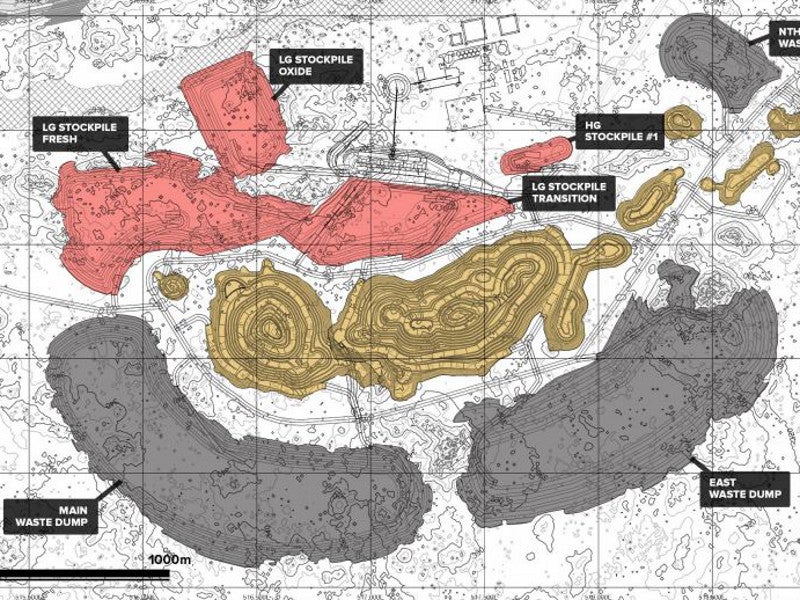

Conventional open-pit mining technique, using trucks and excavators, will be applied at Block 14. A pre-production period of six months will be maintained to separate waste and stockpile feed for commissioning the processing plant.

The processing plant will have a production capacity of 6Mtpa and will feature a single-stage gyratory crusher to produce a crushed size P80 of approximately 110mm. The crushed material will be forwarded to a two-stage grinding circuit comprising a semi-autogenous (SAG) mill and a closed-circuit ball mill.

The grinded ore will undergo pre-leach thickening before being fed to a leach and carbon-in-pulp (CIP) circuit, which reduces the overall reagent consumption. The leaching circuit incorporates a pre-aeration tank to reduce the cyanide consumption rate.

The leached product will be passed on to a Kemix Pumpcell CIP circuit, where carbon is adsorbed. A split 12.5t AARL elution circuit will be used to separate gold and silver from the carbon.

The material will be forwarded to the gold room featuring an electro-winning circuit and mercury retorting to separate mercury from gold. The resultant product will be smelted to produce doré.

Block 14 gold project infrastructure

Water required by the project will be sourced from the aquifer in Area 5, where 17 exploration boreholes and four test production holes were already drilled.

The power supply required for the project is estimated to be 24.3MW, which will be supplied by an on-site heavy fuel oil (HFO)-fuelled power generation plant.

The project comprises a 100‐person exploration camp made from converted sea container and brick buildings, while a satellite camp is proposed to be constructed at Wadi Doum.

Contractors involved

Lycopodium prepared the feasibility study report for the Block 14 gold project, while SRK Consulting conducted geotechnical reviews.

GCS Water & Environmental Consultants provided hydrogeological consultancy services for the project.