Beatrice offshore wind farm is a 588MW project located approximately 13.5km from the coast of Caithness in Scotland, UK.

Beatrice Offshore Windfarm Limited (BOWL), a special consortium company, developed the wind farm. Scottish and Southern Energy (SSE) holds 40% stake in BOWL, while Copenhagen Infrastructure Partners and Red Rock Power hold 35% and 25% respectively.

The project was approved by the Scottish government in March 2014 and reached financial closure in May 2016. Onshore construction works were started in October 2016, while offshore construction was started in April 2017.

The Beatrice project involved an investment of £2.6bn ($3.4bn), making it one of the biggest ever private investments made in Scottish infrastructure.

The first wind turbine at the Beatrice wind project was installed in July 2018 with the help of Pacific Orca vessel, while the last of the 84 turbines was installed in May 2019.

The 588MW wind farm is expected to electrify approximately 450,000 Scottish houses over its estimated operational life of 25 years.

Beatrice offshore wind farm location and make-up

The Beatrice offshore wind farm covers an area of 131km² near the Beatrice and Jacky offshore oil fields. It is located on the north-western point of Smith bank in the Outer Moray Firth, Scotland.

The wind farm consists of 84 Siemens Gamesa SWT-7.0-154 offshore wind turbines, featuring three 75m-long fibreglass-reinforced epoxy blades each.

Each turbine has a rotor diameter of 154m, hub height of 264m, and swept area of 18,600m². A total of 26 jacket substructures, weighing approximately 83,000 tonnes (t), are installed at the project.

The wind farm is operated and monitored from the maintenance base at Wick Harbour.

Power generation and transmission from Beatrice project

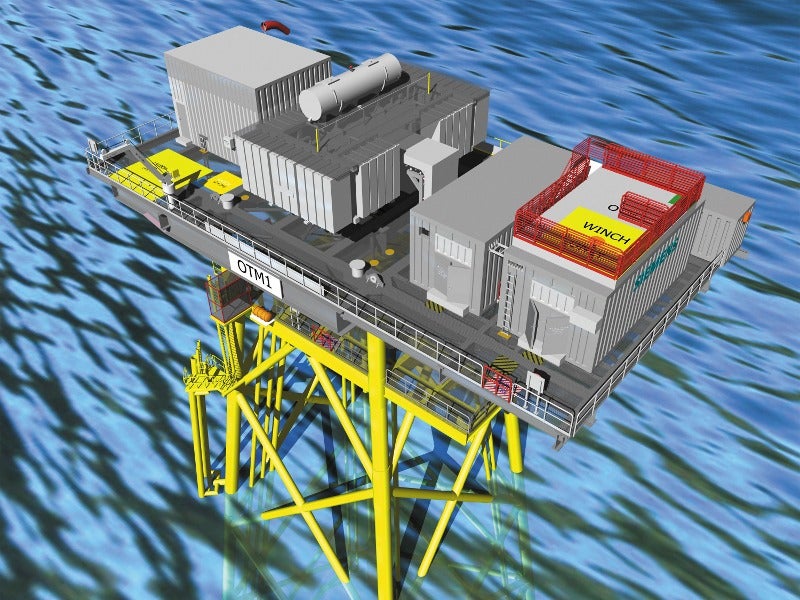

The voltage of power produced by the turbines is converted into 220kV at the offshore transformer modules (OTMs). The electricity is evacuated to the Blackhillock substation located onshore through subsea cables.

Its voltage is further stepped-up to 400kV at the substation for further evacuation to the GB transmission system.

Financing

The Beatrice wind project secured senior debt financing from 13 commercial banks, including a guarantee of £300m ($436m) by EKF (Eksport Kredit Fonden), in May 2016.

European Investment Bank (EIB) provided £525m ($762m) loan facility, under a 19-year long-term loan agreement. A portion of the EIB loan was guaranteed under the European Fund for Strategic Investments.

Power purchase from the Beatrice offshore wind farm

Danske Commodities agreed to offtake 294MW of the power generated by the Beatrice offshore wind farm, under a 15-year power purchase agreement signed in January 2016.

Contractors involved

Subsea 7 manufactured wind turbine foundations and array cables for the Beatrice power project under an engineering, procurement, construction and installation (EPCI) contract. The jacket foundations and array cables were manufactured in association with Seaway Heavy Lifting (SHL).

SHL deployed Stanislav Yudin and Oleg Strashnov heavy-vessels for the offshore installations, while Atkins was engaged for detailed design for the jacket substructures and foundations of the project.

In May 2016, BOWL awarded a contract to Siemens Gamesa, a subsidiary of Siemens, to supply 84 wind turbines for the wind farm. Siemens will also provide service and maintenance for the offshore wind turbines for a period of 15 years.

Siemens also provided onshore and offshore substations and offshore grid connection to the mainland in consortium with Nexans, the supplier of export cables.

Swiss Blue Ocean was sub-contracted for the installation vessels, while RJ McLeod and Glasgow were engaged for the construction of Blackhillock substation.

Burntisland Fabrications (BiFab) manufactured jacket substructures for the project, while Sarens transported and placed the jacket cluster of the offshore wind farm under a sub-contract with BiFab.

JDR Cables provided inter-array cables, while Babcock Rosyth was responsible for the fabrication and construction of the two offshore transformer modules.

Other participants in the wind farm development were DOF Subsea, Bladt Industries, Granada Material Handling, BMO Offshore, NHV Group, TRS Staffing Solutions, Smulders Projects, Sgurr Energy, Red7 Marine, and Hidef Aerial Surveying.