The Arkansas Smackover lithium project, also known as the Lanxess lithium project, is the flagship project of Standard Lithium, a specialty chemical company focussed on developing large-scale lithium brine resources in the US.

The Arkansas Smackover lithium project is located in southern Arkansas, US, the region that houses the biggest brine production and processing facilities in North America.

Standard Lithium announced the positive results of a preliminary economic assessment (PEA) for the Arkansas Smackover lithium project in June 2019. The PEA forecasts up to 20.900 tonnes per annum (tpa) of battery-quality lithium carbonate production over a project life of 25 years, with an estimated capital expenditure of £334m ($437m).

The company completed the installation of an industrial-scale lithium extraction demonstration plant based on its proprietary LiSTR direct lithium extraction technology at one of the Lanxess’s bromine production plants in southern Arkansas in December 2019.

The commissioning of the first-of-its-kind direct lithium extraction demonstration plant is expected in 2020.

Partnership with Lanxess

Standard Lithium plans to develop the lithium project through a joint venture partnership with Lanxess, the largest brine processing operator in the Smackover region of southern Arkansas.

The two companies signed a memorandum of understanding (MoU) to demonstrate the commercial viability of battery-grade lithium extraction from waste brine (tail brine) of Lanxess’s three existing bromine processing facilities in southern Arkansas in May 2018.

Location and site details

The Arkansas Smackover lithium project area covers approximately 150,000 acres, near El Dorado, in southern Arkansas, US. Lanxess owns approximately 10,000 brine leases in the project area.

The Lanxess bromine operations on the mineral-rich Smackover Formation in south Arkansas comprises a total of 65 wells, including 30 brine supply wells and 35 reinjection wells, 400km of brine supply pipelines, and three bromine production plants namely the South, West, and Central plants.

Standard Lithium has also secured the rights for exploration, production and lithium extraction on 27,262 acres of brine leases in a different area on the Smackover Formation in southwest Arkansas, located approximately 40km west of the Lanxess project site. Known as the South-Western Arkansas Tetra project, the area comprises 807 separate brine leases that are held by TETRA Technologies.

Arkansas Smackover lithium resource estimates

The Lanxess lithium project was estimated to contain 3.14 million tonnes (Mt) of indicated Lithium carbonate equivalent (LCE) resources as of June 2019, while approximately 802,000t of maiden inferred LCE resources were reported for the South-Western Arkansas Tetra project in January 2019.

Lanxess brine mining operation at Arkansas Smackover

Raw brine extracted from the 30 brine supply wells in the project area is sent through a network of 400km of pipelines to three processing facilities for bromine recovery.

Each supply well consists of a 1,100HP electrical submersible brine pump with a 17.8cm tubing. The pumps are submersed approximately 1,220m below ground level.

The sour gas produced during the brine extraction is separated at the wellhead by a gas separator. A separate pipeline transports the sour gas to the Central processing plant, from where it is further piped to the Delek Refinery.

Operating for almost the last 50 years, the three bromine extraction plants have been producing up to 5.3 billion gallons of brine annually.

The tail brine from the processing plants is injected back into the aquifer through 35 reinjection wells for maintaining pressure.

Lithium processing for the Lanxess Smackover project

The tail-brine, which is produced as a by-product from the Lanxess’s bromine extraction facilities, will be processed to produce battery-grade lithium carbonate.

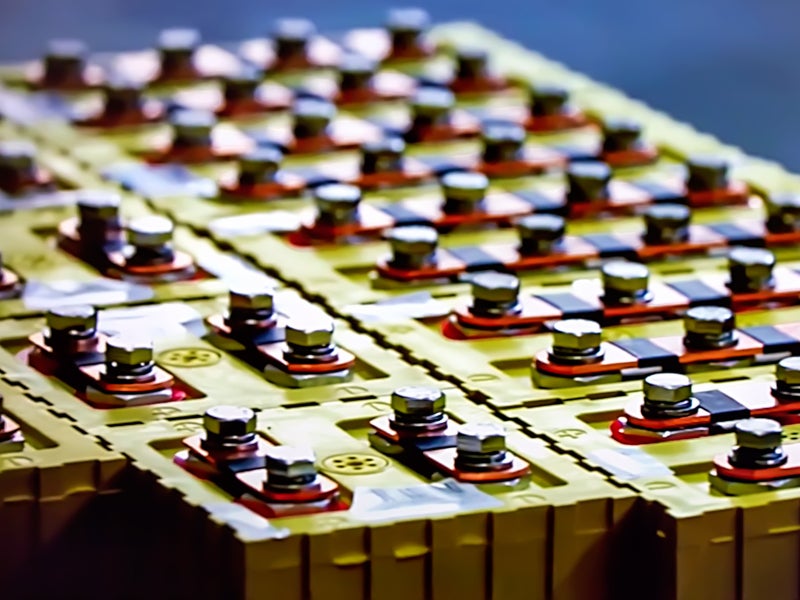

Each of the existing facilities will be added with its own primary lithium chloride extraction plant, where pre-treated tail-brine will be mixed with fine-grained ceramic powder adsorbent to absorb lithium ions.

The purified and concentrated lithium chloride solutions from each plant will be sent through pipelines to a single location at the existing Central bromine extraction facility for the production of lithium carbonate.

The concentrated lithium chloride solution will undergo reverse osmosis (RO) and mechanical vapour recompression (MVR) for further concentration and purification at the lithium carbonate production facility.

A soda ash solution will be used to precipitate the lithium carbonate from the hot lithium chloride solution discharge from the MVR evaporator.

The resultant lithium carbonate will undergo hot washing, drying, and micronisation for the production of the final battery-grade lithium carbonate product.

Southern Arkansas direct lithium extraction demonstration plant details

Standard Lithium installed a pre-commercial direct lithium extraction demonstration plant at Lanxess’s South plant facility in southern Arkansas in December 2019.

Designed to process 50 gallons of tail brine per minute, the demonstration plant is expected to produce up to 150tpa of lithium carbonate a year.

The plant is based on Standard Lithium’s proprietary LiSTR direct lithium extraction technology that uses a solid sorbent material to selectively extract lithium from waste brines.

Contractors involved with the Lanxess lithium project

The PEA for the Lanxess Smackover lithium project was prepared by Advisian, a subsidiary of Worley Parsons.